High glowing filament ignition temperature high-strength polyketone composite material and preparation method and application thereof

A high glow wire and composite material technology, applied in the field of polymer materials, can solve the problems of low strength of flame retardant POK materials, failure to meet high flame retardant requirements, and inability to use, achieve excellent mechanical properties, improve strength and flame retardant. performance, the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

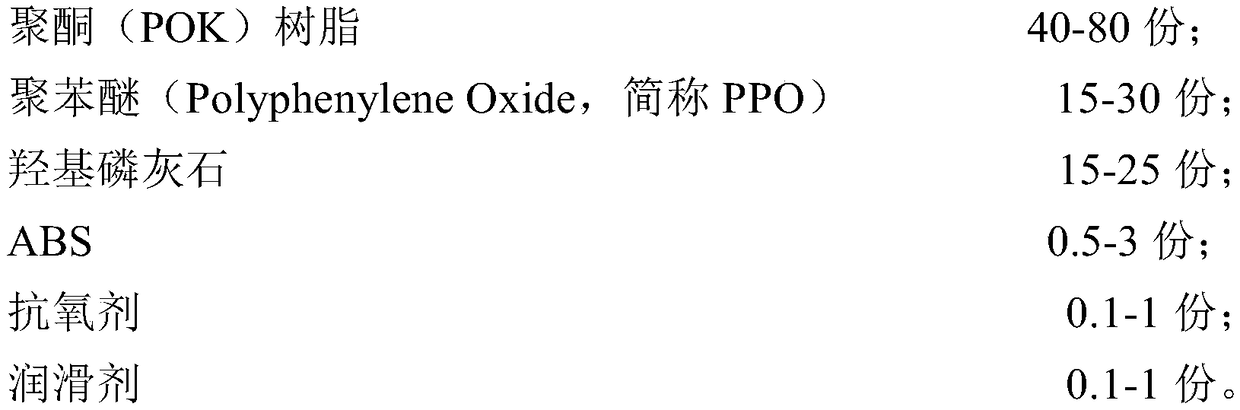

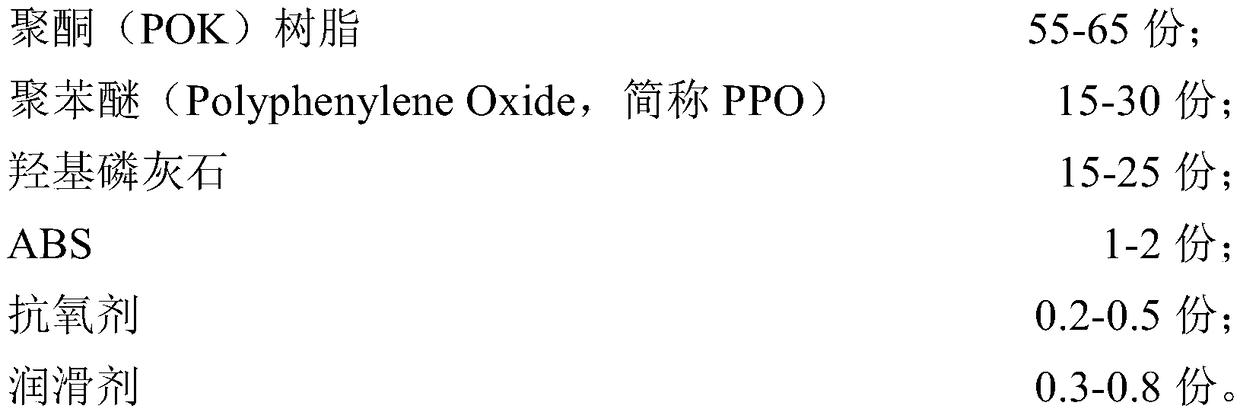

Method used

Image

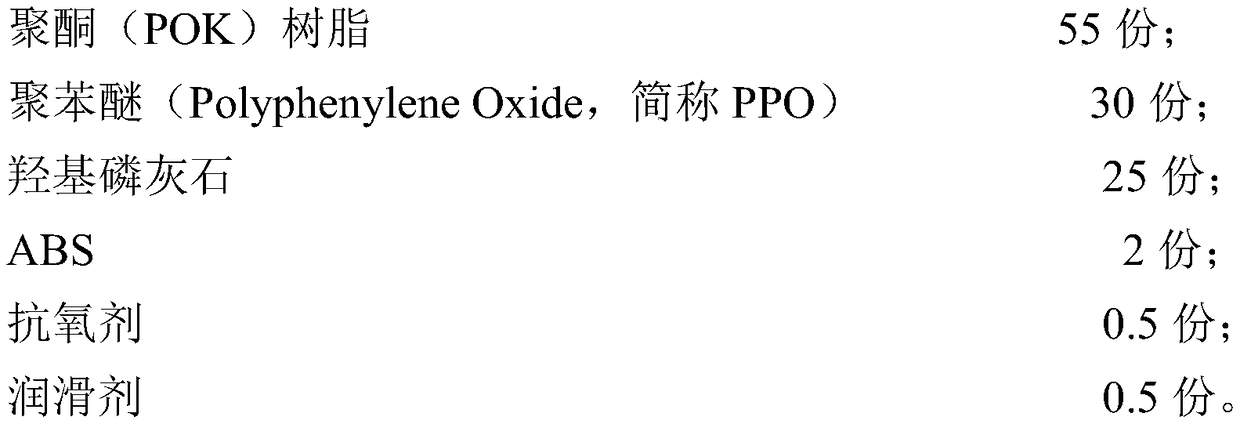

Examples

Embodiment 1~3 and comparative example 1~2

[0039] POK (M330A, Korea Hyosung), PPO (646, SABIC), ABS (727, Taiwan Chimei Company), hydroxyapatite, antioxidant (1098, BASF) and lubricant (sodium stearate , hair-based chemicals) mixed through twin-screw physical extrusion of strands, cooling, and granulation to obtain products. The processing temperature of twin-screw mixed extrusion is 245-280°C, and the screw speed is 30-40Hz.

[0040] The preparation method of hydroxyapatite: 100mL 0.5mol / LCa(NO 3 ) 2 ethanol solution [Ca(NO 3 ) 2 In ethanol solution, the solvent is ethanol, Ca(NO 3 ) 2 The concentration is 0.5mol / L], add 10g sodium dodecylbenzenesulfonate, 10g polyethylene glycol (PEG-400, molecular weight is 380-420), slowly add 50mL P 2 o 5 Ethanol solution (P 2 o 5 In ethanol solution, the solvent is ethanol, P 2 o 5The concentration is 0.5mol / L), the pH was adjusted to 8.5 with ammonia water, and after standing for 5 days, it was treated at 800°C for 6 hours to obtain hydroxyapatite.

[0041] The materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com