Efficient composite powder grinding aid and preparation method thereof

A compound type, grinding aid technology, applied in the cement field, can solve the problems of grinding aid failure and inconvenient use of cement, and achieve the effect of low cost, good grinding aid effect and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

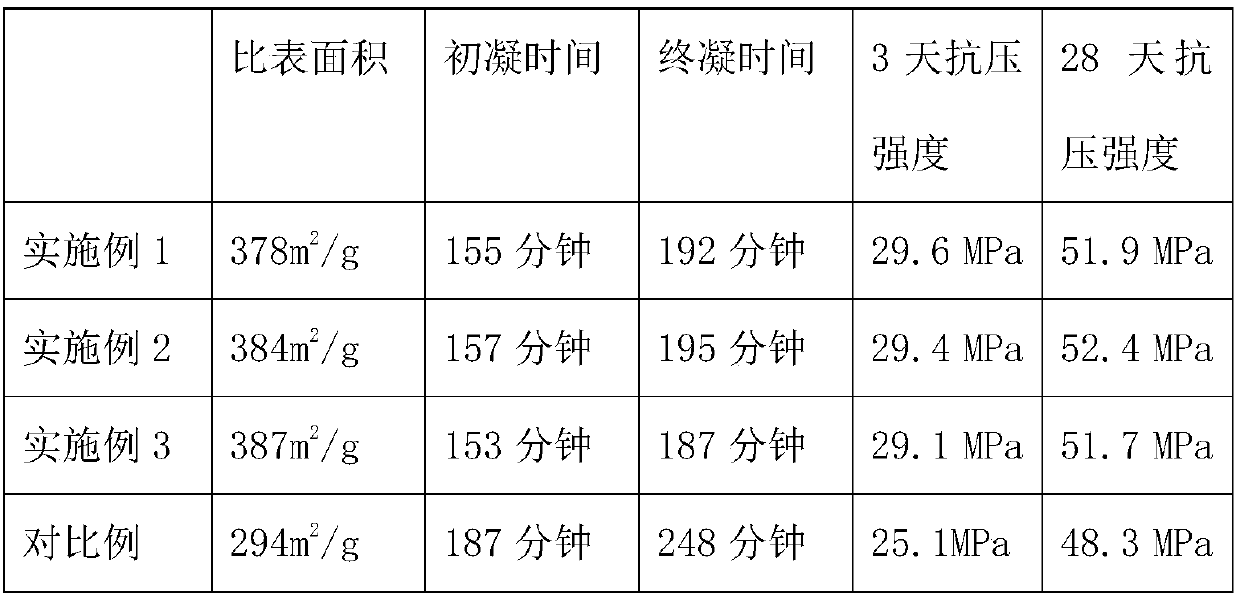

Examples

Embodiment 1

[0020] A high-efficiency composite powder grinding aid, including the following raw materials in parts by weight: 0.8 parts of triethanolamine, 1 part of polyol, 0.3 parts of sodium thiocyanate, 0.8 parts of PC water reducer stock solution, 0.3 parts of sodium hydroxide and steel slag 94 copies. The polyol is a mixture of pentaerythritol and trimethylolethane.

[0021] The preparation method of described high-efficiency composite powder grinding aid, concrete steps are as follows:

[0022] Step 1: Add the stock solution of triethanolamine, polyol and PC water reducer in sequence to the stirring tank and fully mix and react for 2 hours to obtain a mixed solution;

[0023] Step 2: fully mix the steel slag, sodium hydroxide and sodium thiocyanate, then add to the mixed liquid, and mix evenly to obtain the finished product.

Embodiment 2

[0025] A high-efficiency composite powder grinding aid, including the following raw materials in parts by weight: 1 part of triethanolamine, 1.2 parts of polyol, 0.4 part of sodium thiocyanate, 1 part of PC water reducer stock solution, 0.4 part of sodium hydroxide and steel slag 96 servings. The polyol is a mixture of pentaerythritol, glycerin, trimethylolethane and xylitol. The particle size of steel slag is 0.25mm. The mass fraction of PC water reducer stock solution is 35%.

[0026] The preparation method of described high-efficiency composite powder grinding aid, concrete steps are as follows:

[0027] Step 1: Add the stock solution of triethanolamine, polyol and PC water reducer in sequence to the stirring tank and fully mix and react for 2 hours to obtain a mixed solution;

[0028] Step 2: fully mix the steel slag, sodium hydroxide and sodium thiocyanate, then add to the mixed liquid, mix evenly at a mixing speed of 75 rpm, and obtain the finished product.

Embodiment 3

[0030] A high-efficiency composite powder grinding aid, including the following raw materials in parts by weight: 1.5 parts of triethanolamine, 1.8 parts of polyols, 0.6 parts of sodium thiocyanate, 1.5 parts of PC water reducer stock solution, 0.4 parts of sodium hydroxide and steel slag 97.5 servings. The polyhydric alcohol adopts pentaerythritol. The mass fraction of PC water reducer stock solution is 35%.

[0031] The preparation method of described high-efficiency composite powder grinding aid, concrete steps are as follows:

[0032] Step 1: Add the stock solution of triethanolamine, polyol and PC water reducer in sequence to the stirring tank and fully mix and react for 2 hours to obtain a mixed solution;

[0033] Step 2: fully mix the steel slag, sodium hydroxide and sodium thiocyanate, then add to the mixed liquid, and mix evenly to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com