A kind of dull glaze and its preparation method and application

A matte glaze and raw material technology, applied in the field of matte glaze and its preparation, can solve the problems of inability to guarantee, reduce gloss, influence of antifouling ability, etc., and achieve good exhaust gas, less gas production, and good antifouling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

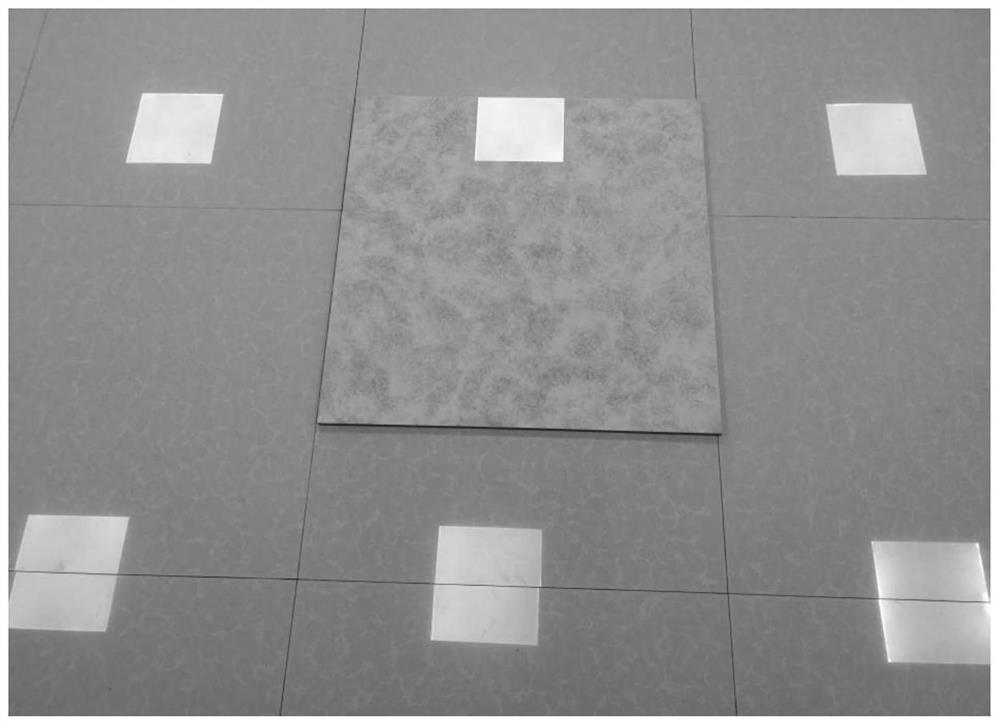

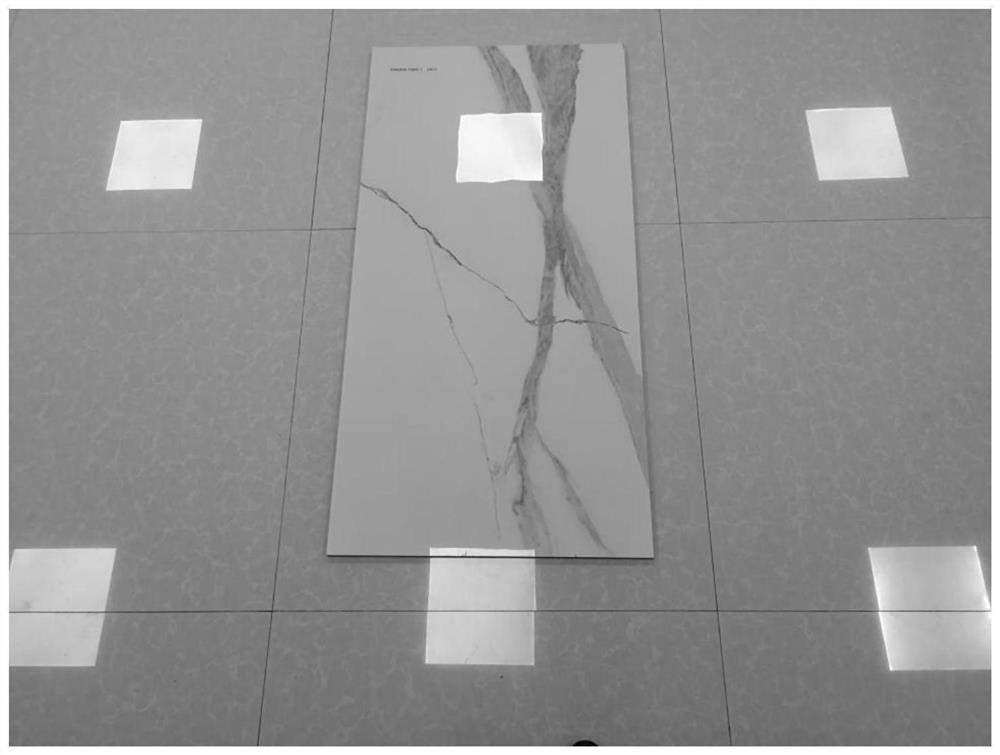

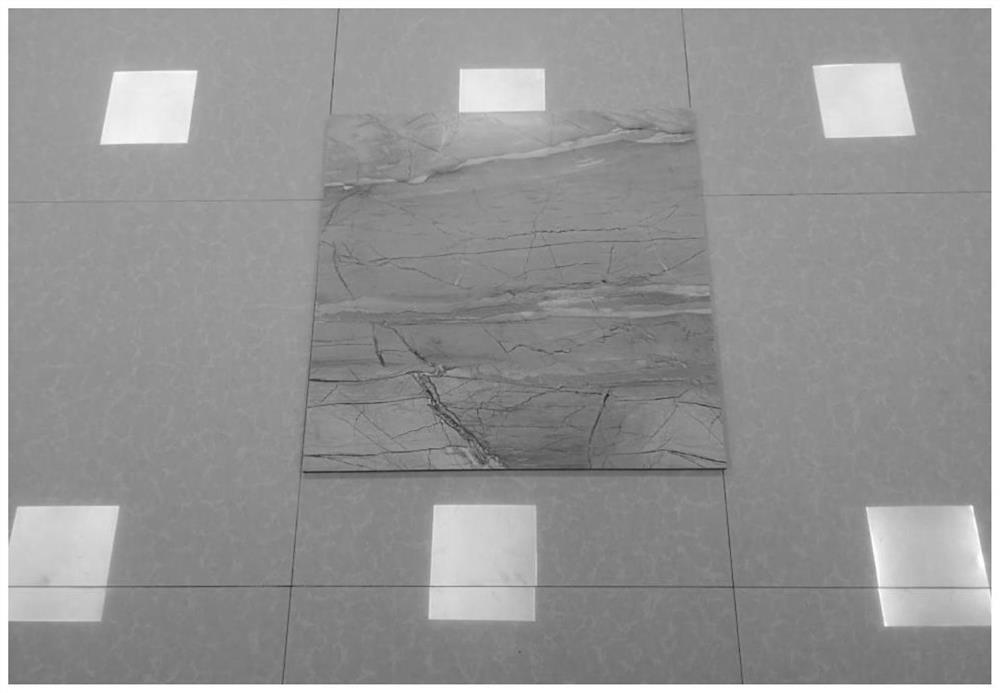

Image

Examples

preparation example Construction

[0037] The second object of the present invention is achieved by the following technical solutions: a method for preparing a matte glaze, comprising the following steps:

[0038] The step of mixing the ingredients: weighing the alumina, boric acid, potassium feldspar, albite, dolomite, barium carbonate, lithium china stone, calcium fluoride and mixing them together;

[0039] Melting step: transport the above-mentioned mixed raw materials into the melting furnace and melt them into molten glass;

[0040] Steps of water quenching: pour the molten glass into the water tank, and water quench to cool it into pellet frit;

[0041] The step of drying; the frit after water quenching is dried with drying equipment;

[0042] The step of crushing: after the frit is dried, it is crushed and sieved to obtain dry granules of matt glaze.

[0043] As a further preferred solution, in the step of melting, the temperature of the melting furnace is 1480-1580°C.

[0044] As a further preferred ...

Embodiment 1

[0061] Example 1 a matte glaze

[0062] The matte glaze is prepared from the following raw materials in parts by weight: 8 parts of alumina, 5 parts of boric acid, 24 parts of potassium feldspar, 9 parts of albite, 24 parts of dolomite, 5 parts of barium carbonate, lithium china stone 20 parts, 3 parts of calcium fluoride.

Embodiment 2

[0063] Example 2 a matte glaze

[0064] The matte glaze is prepared from the following raw materials in parts by weight: 12 parts of alumina, 8 parts of boric acid, 26 parts of potassium feldspar, 12 parts of albite, 28 parts of dolomite, 7 parts of barium carbonate, lithium china stone 30 parts, 5 parts of calcium fluoride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com