Potting system and method for abnormal-shaped container

A container and potting technology, which is applied in the field of potting and sealing systems for special-shaped containers, can solve the problems of increasing the processing cost of specification parts, increasing the difficulty of dial wheel transmission, and lengthening the length of the production line, thereby simplifying machine layout, reducing processing costs, and improving production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

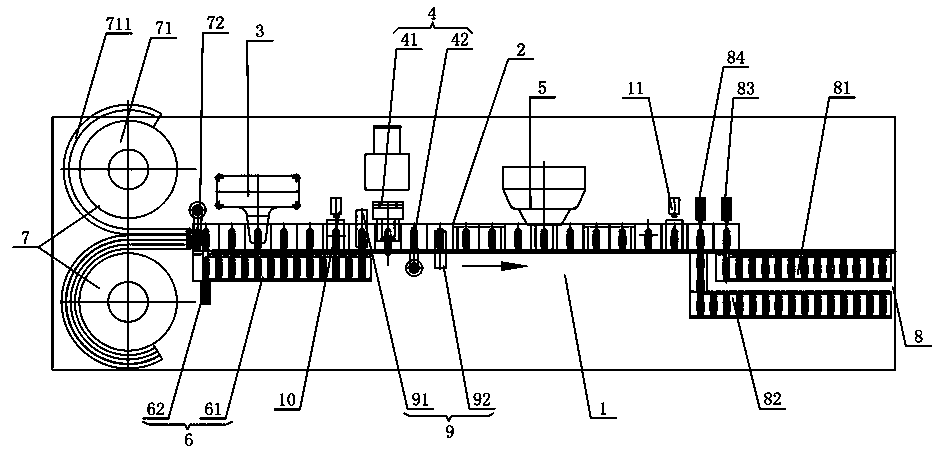

[0051] Figure 1 to Figure 9 It shows the first embodiment of the filling and sealing system for special-shaped containers of the present invention, including a frame 1, a linear conveying line 2 is arranged on the frame 1, and a film adding station is arranged on the linear conveying line 2 3. Aluminum foil packaging station 5 and at least one filling and pressing film station 4, film adding station 3, filling and pressing film station 4 and aluminum foil packaging station 5 are arranged in sequence along the conveying direction of the linear conveying line 2, and the straight line The container input station 6 and the film feeding station 7 are provided at the head end of the linear conveyor line 2, the container output station 8 is provided at the end of the linear conveyor line 2, and the container filling station 8 is also provided on the linear conveyor line 2. Quantity measuring device9. When the system is running, the film and container are sent to the linear conveyin...

Embodiment 2

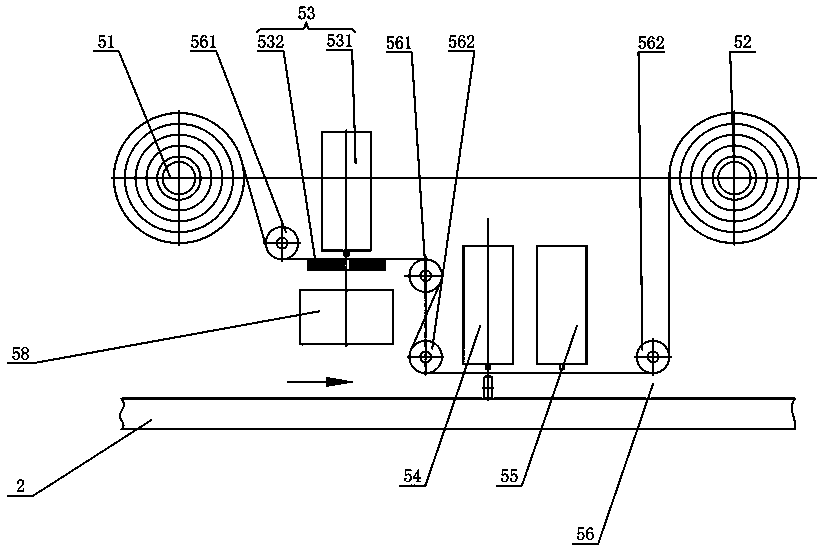

[0065] Such as Figure 10 with Figure 11 As shown, the second embodiment of the potting system for special-shaped containers, the potting system is basically the same as Embodiment 1, the only difference is: in this embodiment, the first conveying roller 51, the aluminum foil punching Machine 53 , aluminum foil sheet pressing machine 54 , aluminum foil sheet ultrasonic sealing machine 55 and second conveying roller 52 are arranged in sequence along the direction perpendicular to the conveying direction of linear conveying line 2 . This arrangement makes the overall travel direction of the aluminum foil belt perpendicular to the conveying direction of the bottle conveyor belt 1, which is suitable for cross-type models.

Embodiment 3

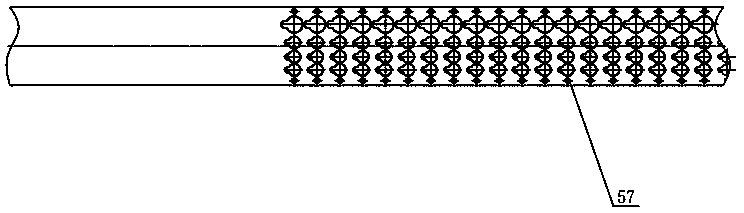

[0067] Such as Figure 12 with Figure 13 As shown, the third embodiment of the potting system for special-shaped containers, the potting system is basically the same as Embodiment 1, the only difference is: in this embodiment, the filling station 41 and the film pressing station 42 Correspondingly, there are multiple sets, and multiple outer filling needles 414 and film pressing rods 421 are also provided correspondingly. The filling station 41 and the film pressing station 42 are alternately arranged, and the first and last stations of the filling film pressing station 4 are respectively filling The station 41 and the film pressing station 42, the connecting rod 4141 connects the outer irrigation needles 414 and the film pressing rod 421, and the outer irrigation needles 414 and the film pressing rod 421 are alternately arranged on the connecting rod 4141. Such arrangement can be applied to the filling pressure of large batches of different types of container rows, and each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com