Die carrier for ceramimetallurgical automotive engine piston

An automobile engine and powder metallurgy technology, applied in the field of powder metallurgy automobile parts, can solve the problems of complex production equipment, waste of energy, uniform distribution of difficult-to-enhance particles and gradient distribution, etc., so as to reduce the waste of materials and energy, and avoid the existence of pouring risers. , the effect of increasing strength

Inactive Publication Date: 2018-12-28

JILIN UNIV

View PDF10 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at casting defects such as slag inclusions, pores, shrinkage cavities, and cold shuts that may exist in the existing piston manufacturing process, casting riser materials, energy waste, a large number of processing defects such as tearing and burrs during mechanical processing, and complex production equipment, It is difficult to achieve a series of problems such as uniform distribution and gradient distribution of reinforced particles. The present invention proposes a mold base for manufacturing high-quality, high-density, high-strength automobile engine pistons by powder metallurgy, which is more convenient for manufacturing ceramic particles with uniform or Gradient-enhanced aluminum-silicon engine pistons effectively reduce machining and material waste

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

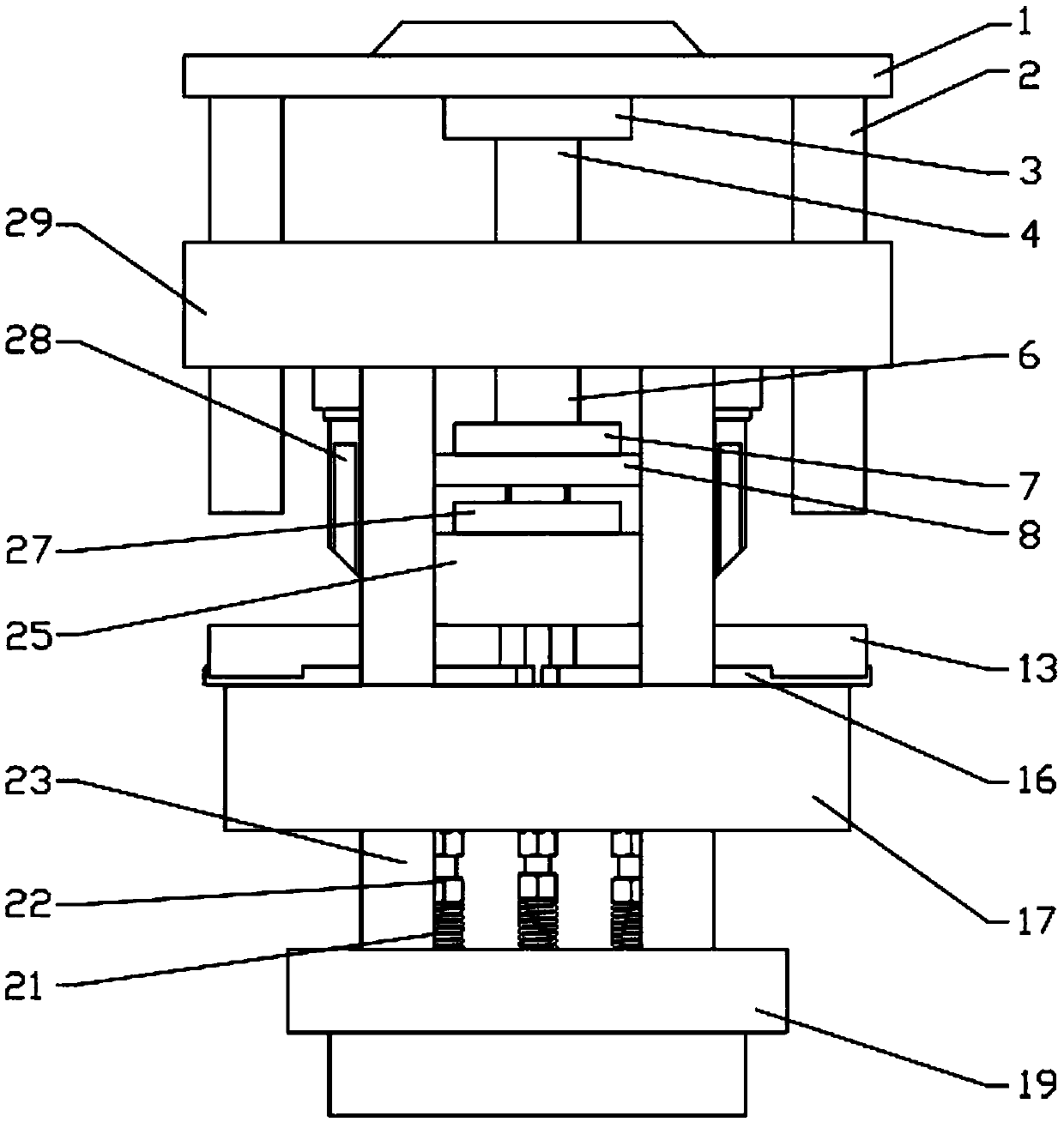

The invention provides a die carrier for a ceramimetallurgical automotive engine piston. On the basis of a pull down type standard die carrier, the positions and structures of parts such as a first lower punch, a second lower punch and a third lower punch are reasonably distributed and designed; after a powder loading shoe loads piston powder into a female die cavity of the die carrier, compression molding of the automotive engine piston is completed by using the lifting action of a lifting rod, the locating action of a sliding block and a yoke-shaped plate and the pressure action of the upperand lower punches; then the whole die carrier is put into a high-temperature furnace and is heated till the temperature is below a powder liquid phase line, and the temperature is preserved for a period of time to complete manufacturing of a ceramimetallurgical blan of the piston; and finally, the automotive engine piston is manufactured and molded through machining of an air ring, an oil ring and the like. According to the die carrier, the automotive engine piston with high quality, high compactness and high intensity can be manufactured, and an aluminum-silicon engine piston with uniform ceramic particles or enhanced gradient can be manufactured more conveniently; and machining and the waste of materials are effectively reduced.

Description

technical field The invention belongs to the field of powder metallurgy automobile parts, and in particular relates to a mold base for powder metallurgy automobile engine pistons, which is suitable for manufacturing high-quality, high-density, high-strength automobile engine pistons, especially aluminum-silicon engines uniformly reinforced by ceramic particles Pistons and aluminum-silicon engine pistons reinforced with gradient ceramic particles. Background technique The engine is the device that provides power for the whole vehicle, which can be called the "heart" of the car, and the engine piston plays an important role in the work of the engine and is a key part of the engine. Due to the harsh service environment, pistons often need to withstand large mechanical loads and high thermal loads. Therefore, pistons are generally required to have low density, high strength, good wear resistance, high temperature resistance, good thermal conductivity, fatigue resistance, and goo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22F3/03

Inventor 呼咏吴彤郭锦洲宋明凯王文阳石栋陈思远郭悦王宇付忠国

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com