Hiberarchy biomass carbon fiber/TiO2 photocatalytic degradation ammonia nitrogen material and preparation method thereof

A biomass charcoal, hierarchical structure technology, applied in physical/chemical process catalysts, chemical instruments and methods, water pollutants, etc. Efficient and rapid removal of ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

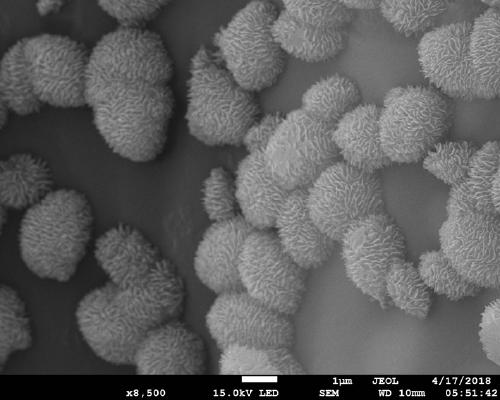

Image

Examples

Embodiment 1

[0032] Hierarchical Structure Biomass Carbon Fiber / TiO 2 The preparation method of photocatalytic degradation ammonia nitrogen material comprises the following steps:

[0033] a) Cut the waste cotton into pieces, add 100mL alkali solution to 40g of biomass raw material, add it to a sodium hydroxide solution with a mass fraction of 3wt%, stir it for 4 hours at 80°C, take it out and use deionized water Wash until neutral, tumble dry. Prepare 2wt% NaClO 2 solution and adjust the pH value to 4 with acetic acid, and disperse the above dried sample in NaClO 2 Bleach was carried out in the solution, stirred at 70°C for 5 hours, then washed with deionized water and ethanol until neutral, and dried in an oven at 70°C for 12 hours to obtain biomass fibers.

[0034] b) Place the biomass fiber in a tube furnace, raise the temperature up to 400°C at a rate of 5°C / min, calcinate for 2 h under the protection of nitrogen, and cool naturally to obtain the biomass carbon fiber.

[0035] c) ...

Embodiment 2

[0040] Hierarchical Structure Biomass Carbon Fiber / TiO 2 The preparation method of photocatalytic degradation ammonia nitrogen material comprises the following steps:

[0041]a) After cutting the waste cotton into pieces, add 50g of biomass raw material into 100mL alkali solution, add it into the sodium hydroxide solution with a mass fraction of 9wt%, stir it for 4 hours at 80°C, take it out and use deionized water Wash until neutral, tumble dry. Prepare 5wt% NaClO 2 solution and adjust the pH value to 4 with acetic acid, and disperse the above dried sample in NaClO 2 Bleaching was carried out in the solution, stirred at 70°C for 5 hours, then washed with deionized water and ethanol until neutral, and dried in an oven at 70°C for 12 hours to obtain biomass fibers.

[0042] b) Put the biomass fibers in a tube furnace, raise the temperature up to 500°C at a rate of 8°C / min, calcinate for 3 h under the protection of nitrogen, and cool naturally to obtain biomass carbon fibers....

Embodiment 3

[0048] Hierarchical Structure Biomass Carbon Fiber / TiO 2 The preparation method of photocatalytic degradation ammonia nitrogen material comprises the following steps:

[0049] a) After shredding hemp, add 60g of biomass raw material to 100mL alkali solution, add it to sodium hydroxide solution with a mass fraction of 5wt%, stir for 4 hours at 80°C, take it out and wash it with deionized water to neutral, tumble dry. Prepare 8wt% NaClO 2 solution and adjust the pH value to 4 with acetic acid, and disperse the above dried sample in NaClO 2 Bleaching was carried out in the solution, stirred at 70°C for 5 hours, then washed with deionized water and ethanol until neutral, and dried in an oven at 70°C for 12 hours to obtain biomass fibers.

[0050] b) Put the biomass fibers in a tube furnace, raise the temperature up to 600°C at a rate of 10°C / min, calcinate for 4 h under the protection of nitrogen, and cool naturally to obtain biomass carbon fibers.

[0051] c) Prepare the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com