Leachate back-injection system of garbage incineration boiler and method for reducing NOx content

A technology for waste incineration and leachate, which is applied in separation methods, chemical instruments and methods, and nitrous oxide capture, etc., can solve the problems of inability to process leachate, excessive NOx content, and large environmental pollution. Stabilizing, reducing NOx emissions, and cleaning flue gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

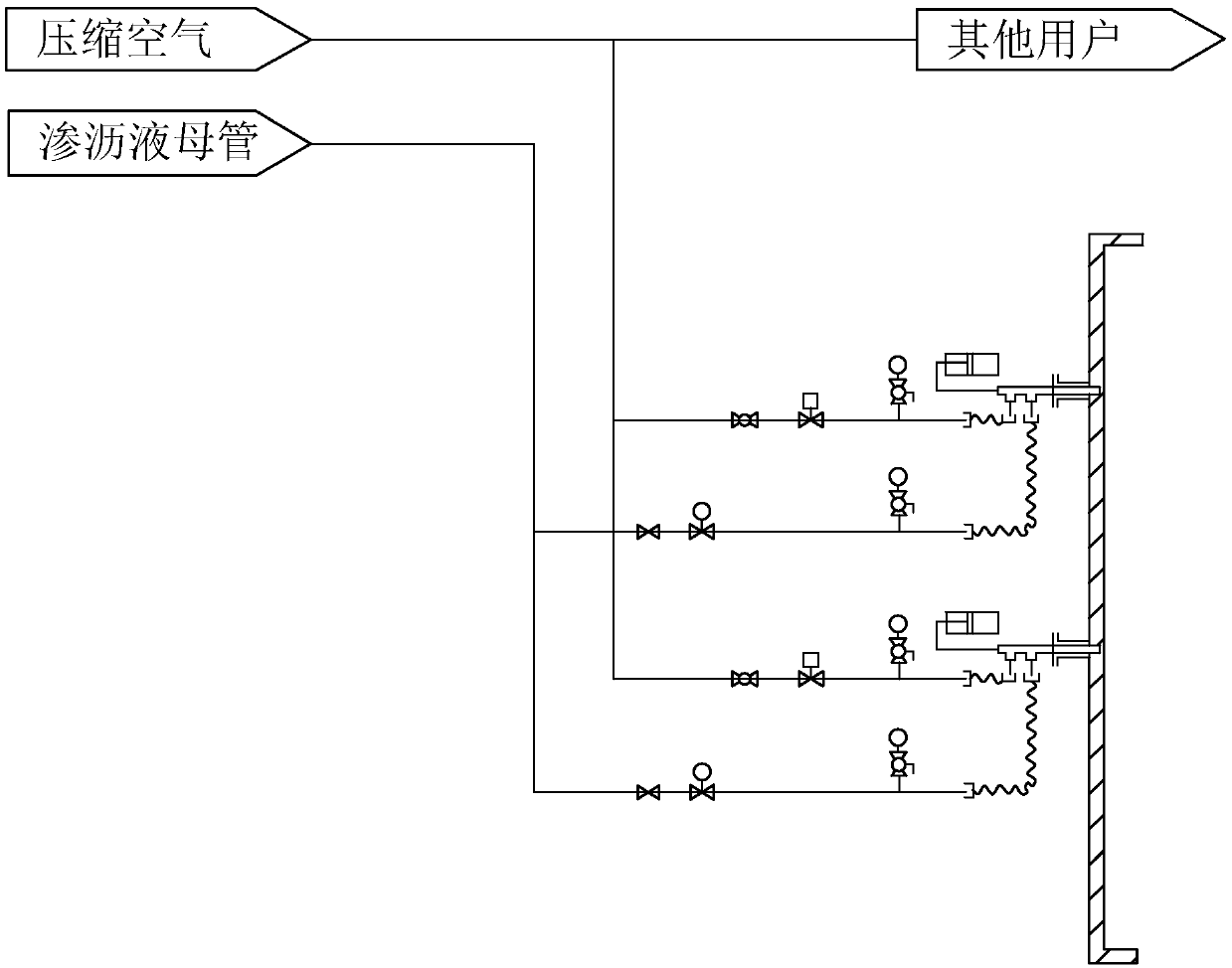

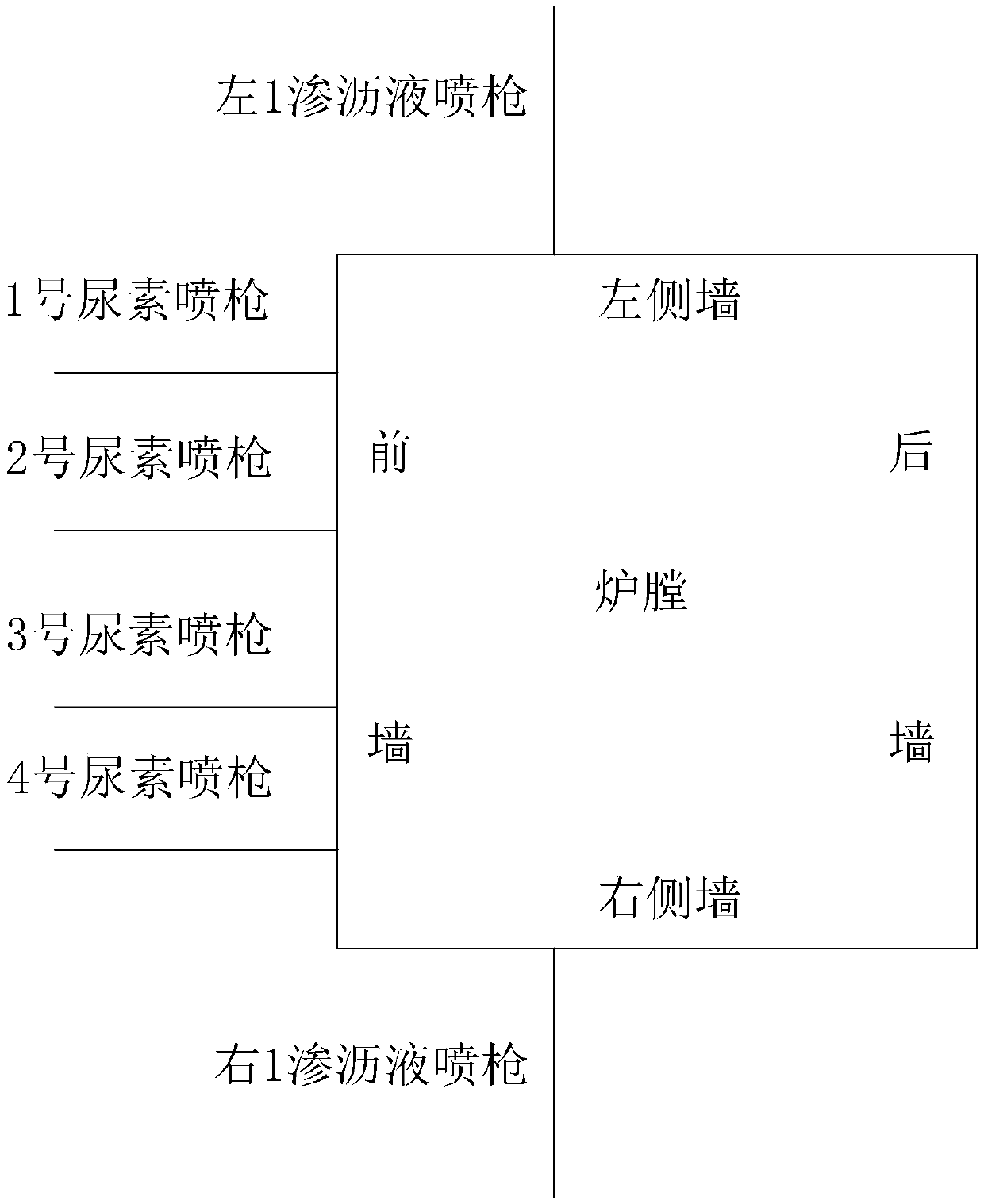

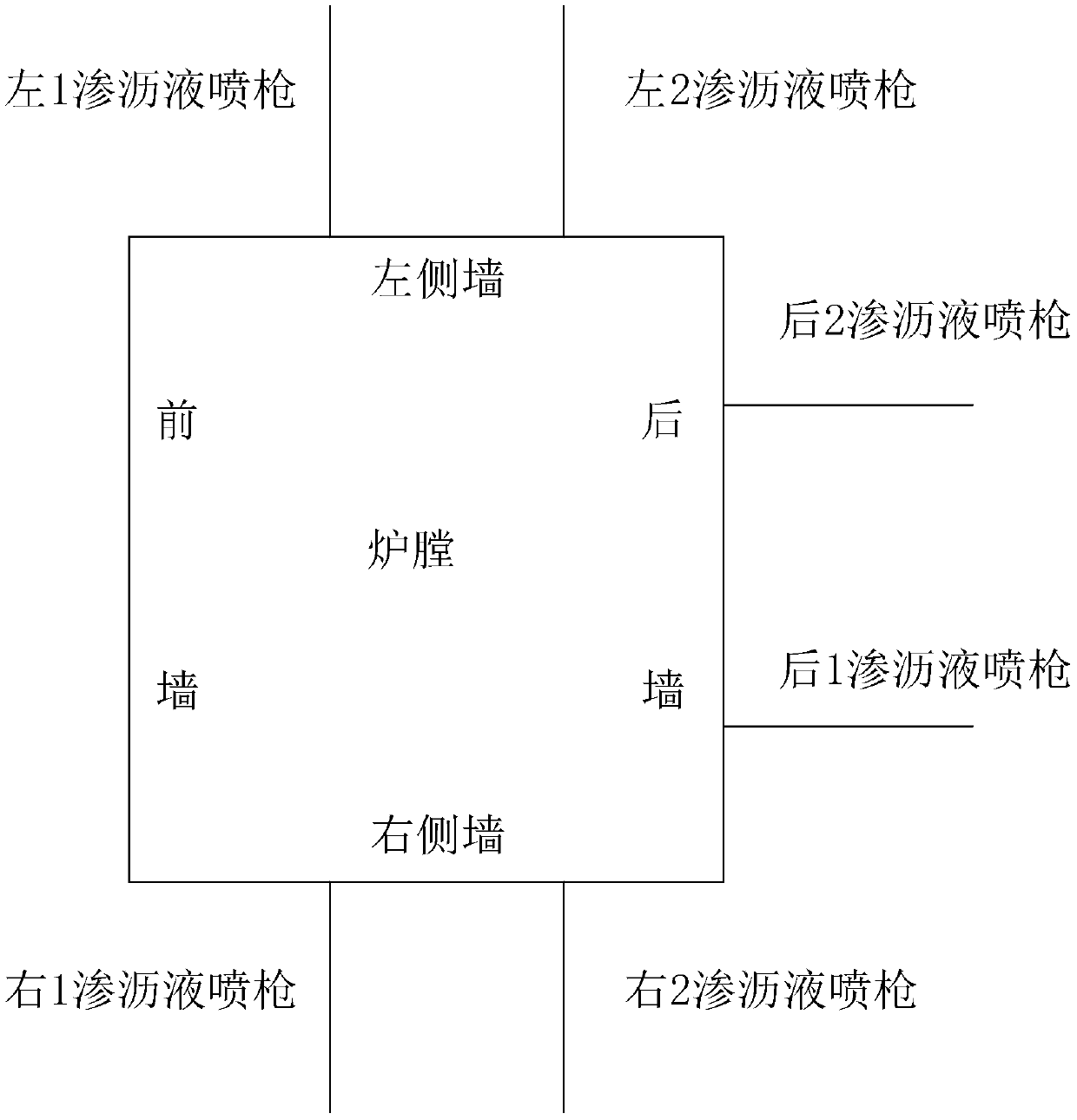

[0057] Embodiment 1: A kind of waste incineration boiler leachate return spraying system, such as figure 1 with figure 2 As shown, it includes a urea injection device and a leachate return spray device. The urea injection device includes a urea spray gun installed on the waste incineration boiler. The leachate return spray device includes a leachate spray gun installed on the waste incineration boiler. The leachate The spray gun is connected to the external source of compressed air and leachate through pipelines. Control valves and flow meters are respectively installed on the pipelines. The ammonia nitrogen in the urea and leachate and the NOx produced by waste incineration undergo denitrification reactions during the combustion process, reducing NOx content in exhaust gas.

[0058] refer to figure 1 with figure 2 , There are multiple main pipelines for compressed air, so that other users can also use compressed air.

[0059] The urea injection device also includes a ur...

Embodiment 2

[0084] Embodiment 2: A kind of waste incineration boiler leachate return spraying system, such as Figure 11 As shown, the difference from Embodiment 1 is that an air storage tank is connected to the main compressed air pipeline, and a leachate sewage discharge pipe is installed at the bottom of the air storage tank, and a control valve is installed on the sewage discharge pipe.

[0085] Compared with Embodiment 1, the advantages are: 1) Adding a compressed air storage tank to supply air separately for the leachate back spraying device can ensure that the pressure of the compressed air is relatively stable, and avoid the pressure of the compressed air due to the large number of users of the main compressed air pipeline. The pressure changes greatly, and the atomization effect is unstable;

[0086] 2) Even if the atomizing nozzle 4 is blocked, the leachate can only flow into the air storage tank along the pipeline, and it can also prevent the leachate from entering the compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com