A combined bidirectional DC-DC conversion circuit

A bidirectional DC conversion and combined technology, applied in the field of DC non-isolated conversion devices, can solve the problems of increased winding difficulty and increased loss, and achieve the effect of simple control scheme, easy implementation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

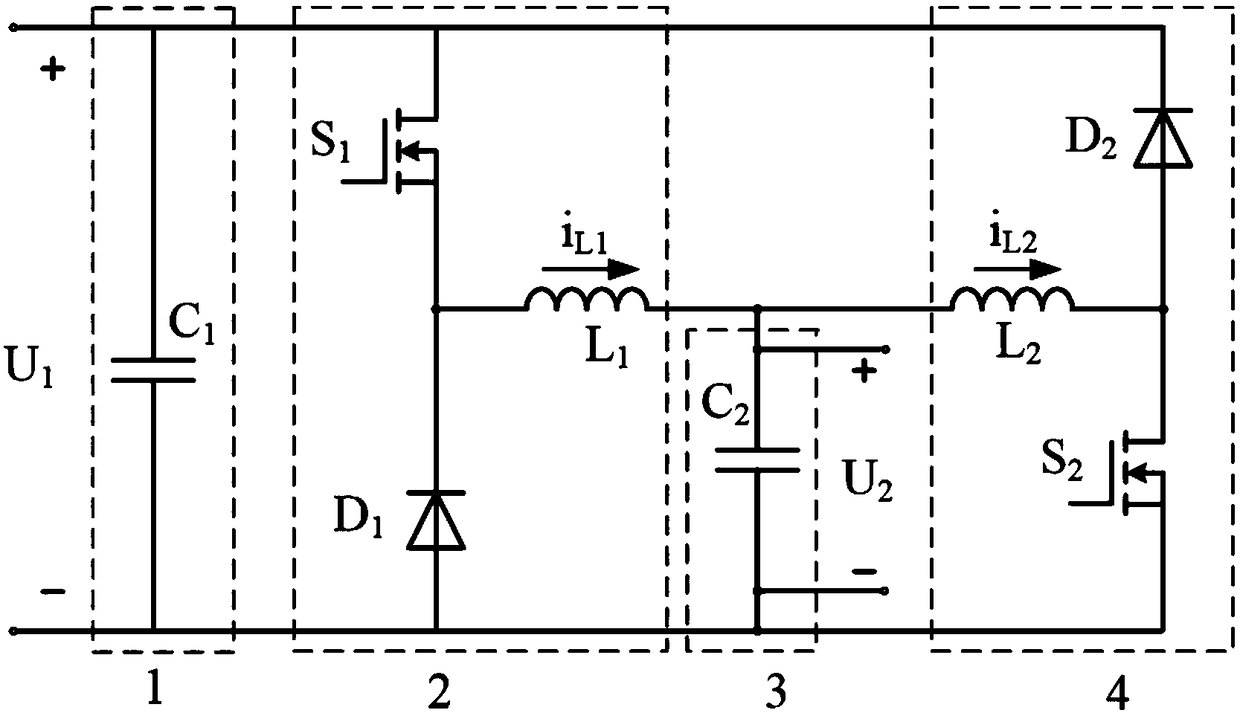

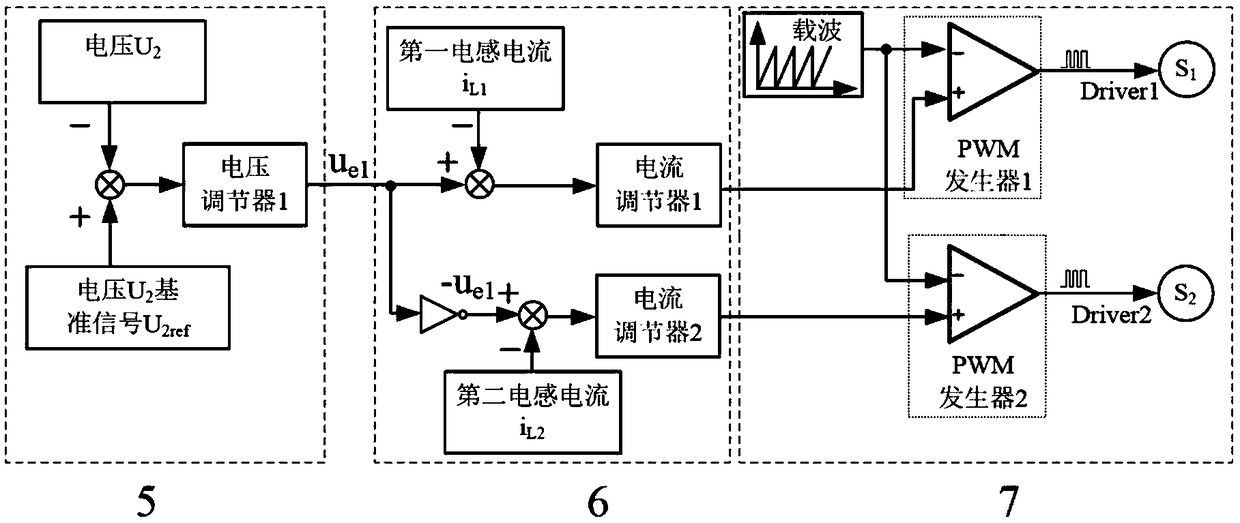

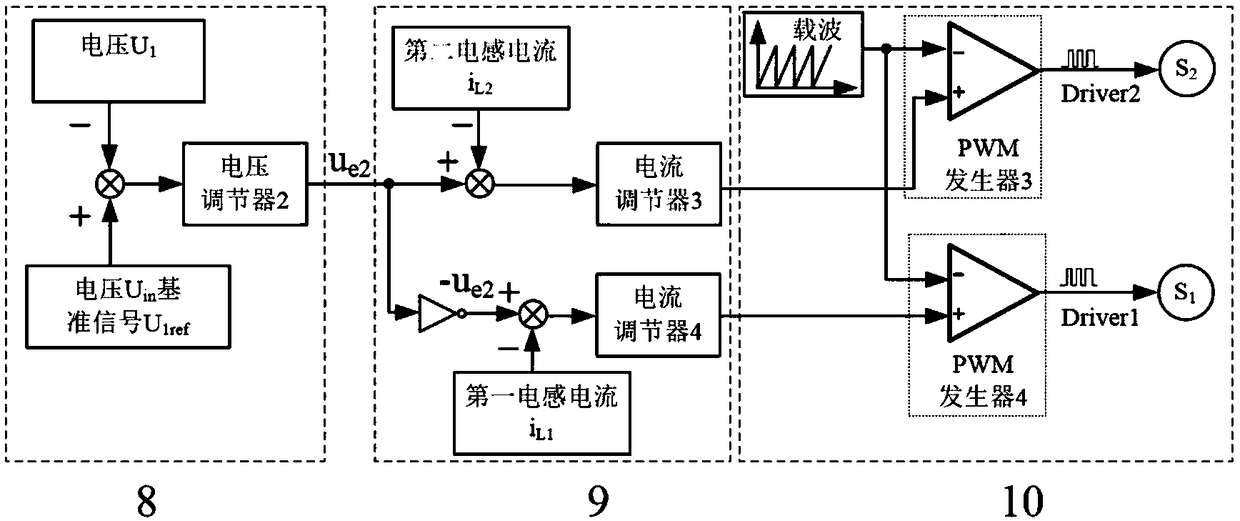

[0043] refer to Figure 1-3 , a combined bidirectional DC conversion circuit and its control method, which includes a first-end filter capacitor 1, a step-down bridge arm circuit 2, a second-end filter capacitor 3, a boost bridge arm circuit 4, a first total voltage Ring controller 5, the first total current loop controller 6, the first total PWM generator 7, the second total voltage loop controller 8, the second total current loop controller 9, the second total PWM generator 10; the first The terminal filter capacitor 1 includes: the first terminal filter capacitor C 1 , where the first power switch S 1 The drain of the second freewheeling diode D 2 The cathode of the two is connected, and the first end of the filter capacitor C is connected to the connector of the two 1 One end of the first freewheeling diode D 1 The anode of the second power switch tube S 2 The source is connected, and the first end of the filter capacitor C is connected to the connector of the two 1 ...

Embodiment 2

[0045] Referring to FIGS. 4-5 , the working principle of the combined bidirectional DC conversion circuit and its control method described in Embodiment 1 is divided into two parts. The breakdown is as follows:

[0046] 1. The working part of the step-down bridge arm circuit

[0047] When power is needed from the first terminal filter capacitor C 1 End to second end filter capacitor C 2 end, when it flows, the step-down bridge arm circuit 2 works, and the step-up bridge arm circuit 4 does not work, and the electric energy is transferred to the filter capacitor C at the second end through the first inductance L1 2 end delivery. This part of the circuit has two working modes:

[0048] 1. Working mode I

[0049] As shown in Figure 4(a), the first switching tube S 1 conduction, the first terminal filter capacitor C 1 terminal power to the second terminal filter capacitor C 2 end delivery, the first freewheeling diode D 1 , the second power switch tube S 2 , the second fr...

Embodiment 3

[0059] refer to Figure 6-13 . The main simulation experiments are done with a combined bidirectional DC conversion circuit and its control method described in Embodiment 1 and Embodiment 2.

[0060] The simulation parameters are as follows: the switching frequency is 50kHz, the first inductor L 1 inductance and the second inductance L 2 The inductance is 100μH, the filter capacitor C at the first end 1 and the second terminal filter capacitor C 2 They are 1000μF, and the load R is a 2Ω resistive load.

[0061] Figure 8 , Figure 9 and Figure 10 given by the second terminal filter capacitor C 2 Terminal voltage U 2 Some main simulation waveforms of the example of the present invention when it is the control object. The first end filter capacitor C 1 Terminal voltage U 1 is a 48V voltage source, the second terminal filter capacitor C 2 Terminal voltage U2 is controlled at 24V.

[0062] From Figure 8 , Figure 10 It can be seen that: when the injected current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com