Tire tread rubber composition and preparation method thereof

A rubber composition and a technology for tire treads, applied in the field of tire rubber, can solve the problems of poor wear resistance, no obvious improvement effect, and high rolling resistance, and achieve improved braking performance on ice and snow, improved antistatic performance, and reduced increase in size. gentle volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

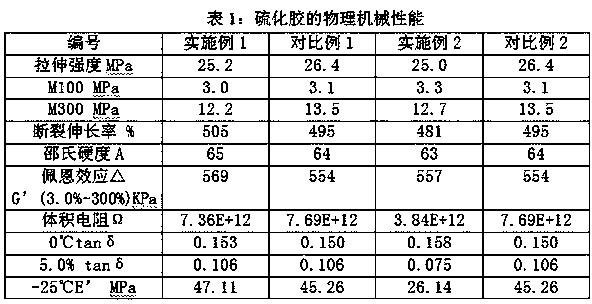

Embodiment 1

[0026] 1. Prepare 264 g of pre-ball milled silica modified by coupling agent; prepare 13 g of graphene oxide powdery solid.

[0027] 2. Preparation of tire tread rubber composition containing graphene oxide / silica composite material:

[0028] (1) One stage mixing: the rotor speed is 40-100rpm, the mound pressure: 0.2-0.8MPa, first add the above 0.7kg natural rubber, 7.4g dispersant, 11.1g paraffin and microcrystalline wax, and 14.7g active agent into the dense Mixing in the mill for 30-50s; lift the plug, add 50g carbon black, 264g pre-milled coupling agent modified silica prepared in step 1, and 13g graphene oxide solid prepared in step 1, press the plug, Mix for 10-100s; raise the plug, add 73g carbon black, 25.8g remaining active agent, 22.1g anti-aging agent, press the plug, and mix for 10-200s to obtain a masterbatch.

[0029] (2) One-stage parking: Put the one-stage masterbatch prepared in step 1 in the air and cool to room temperature naturally.

[0030] (3) Final mixing: Roto...

Embodiment 2

[0036] 1. Prepare uniformly dispersed graphene oxide / silica composite material A1 containing 264 g of coupling agent modified pre-ball milled silica and 13 g of graphene oxide.

[0037] 2. Preparation of tire tread rubber composition containing graphene oxide / silica composite material:

[0038] (1) One-stage mixing: rotor speed is 40-100rpm, mound pressure: 0.2-0.8MPa, first add 0.7kg natural rubber, 7.4g dispersant, 11.1g antioxidant paraffin and microcrystalline wax, and 14.7g active agent Mixing in the internal mixer for 30-50s; then lift the plug, add 50g carbon black, 277g composite material A1 prepared in step 1, press the plug, and mix for 10-100s; lift the plug, add 73g carbon black, 47.9g anti-aging 4020, RD and the remaining active agent zinc oxide are mixed for 10-200s to obtain a masterbatch.

[0039] (2) One-stage parking: Put the one-stage masterbatch prepared in step 1 in the air and cool to room temperature naturally.

[0040] (3) Final mixing: Rotor speed 0-80rpm, mo...

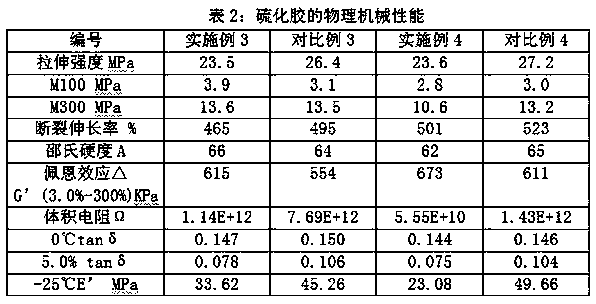

Embodiment 3

[0046] 1. Prepare uniformly dispersed graphene oxide / silica composite material A2 containing 264g of coupling agent modified pre-ball milled silica and 25g of graphene oxide.

[0047] 2. Preparation of tire tread rubber composition containing graphene oxide / silica composite material:

[0048] (1) One stage mixing: rotor speed is 40-100rpm, mound pressure: 0.2-0.8MPa, first add 0.7kg natural rubber, 7.4g dispersant, 11.1g antioxidant paraffin and microcrystalline wax, and 14.9g active agent Mix for 30-50s in the internal mixer; raise the plug, then add 50g carbon black and 293g of the composite material A2 prepared in step 1, press the plug, and mix for 10-100s; raise the plug, add 61g carbon black, 47.9g anti-aging 4020, RD and remaining active agent zinc oxide, etc., are mixed for 10-200s to obtain a masterbatch.

[0049] (2) One-stage parking: Put the one-stage masterbatch prepared in step 1 in the air and cool to room temperature naturally.

[0050] (3) Final refining: rotor speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com