Method of preparing bioactive phospholipid from tuna eyes

A bioactive, tuna-based technology, applied in the field of food processing, can solve problems such as phospholipid research that has not been reported, and achieve the effect of enriching market space and promoting healthy development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

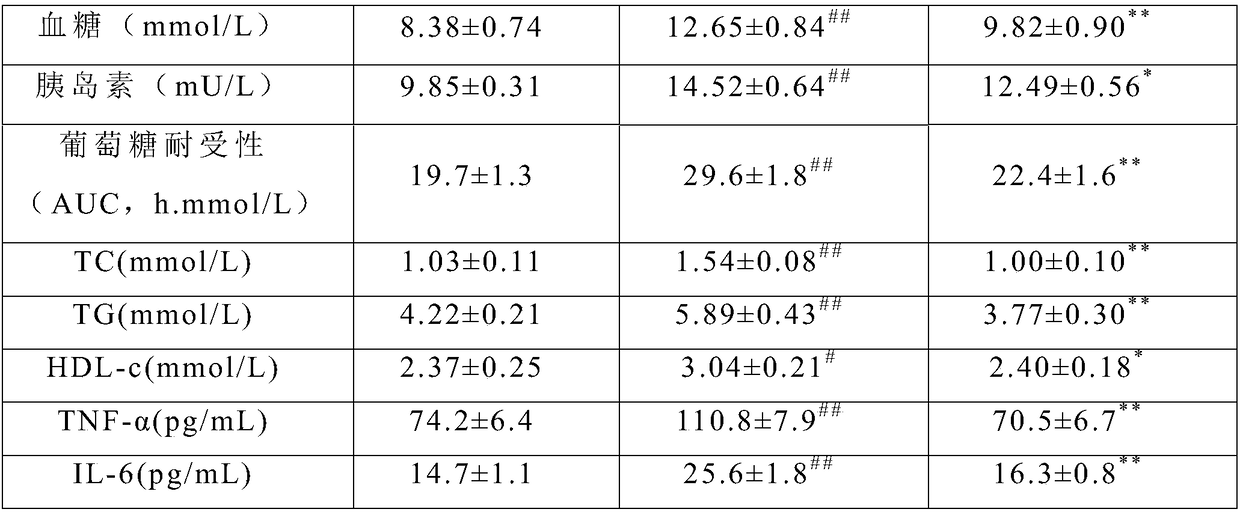

Examples

Embodiment 1

[0040] This implementation case shows a method for preparing highly bioactive phospholipids from tuna eyes according to the following steps:

[0041]Take tuna eyes (10 times the diameter of tuna fish eyes), remove fish bones, add 95% alkaline ethanol solution (fish eye weight: solution volume is 1:5), homogenize at 4 °C for 15 minutes, in which 95% alkali The neutral ethanol solution is to add NaOH to 95% ethanol to make it pH 10.0. Under the action of ultrasonic waves, stir and extract the phospholipid-containing lipids in the eyes of tuna. The extraction time is 2 hours, and the extraction temperature is 40°C. During the extraction period, ultrasonic-assisted extraction is performed intermittently every 30 minutes. 60W / cm 2 , the ultrasonic frequency is 25kHz. After the extraction, filter with three layers of gauze and three layers of filter paper respectively, take the filtrate and distill it under reduced pressure at 40°C to collect the lipid fraction, and the ethanol ca...

Embodiment 2

[0043] This implementation case shows a method for preparing highly bioactive phospholipids from tuna eyes according to the following steps:

[0044] Take the tuna eye (12 times the diameter of the tuna fish eye), remove the fish bones, add 95% alkaline ethanol solution (fish eye weight: solution volume is 1:8), homogenize at 4 ° C for 18 minutes, in which 95% alkali The neutral ethanol solution is to add NaOH to 95% ethanol to make it pH 10.5. Under the action of ultrasonic waves, stir and extract the phospholipid-containing lipids in the eyes of tuna. The extraction time is 3 hours, and the extraction temperature is 50°C. During the extraction period, ultrasonic-assisted extraction is performed intermittently every 30 minutes. 80W / cm 2 , the ultrasonic frequency is 25kHz. After the extraction, filter with three layers of gauze and three layers of filter paper respectively, take the filtrate and distill it under reduced pressure at 42°C to collect the lipid fraction, and th...

Embodiment 3

[0046] This implementation case shows a method for preparing highly bioactive phospholipids from tuna eyes according to the following steps:

[0047] Take tuna eyes (15 times the diameter of tuna fish eyes), remove the fish bones, add 95% alkaline ethanol solution (fish eye weight: solution volume is 1:10), homogenize at 4 °C for 20 minutes, in which 95% alkali The neutral ethanol solution is to add NaOH to 95% ethanol to make it pH 11.0. Under the action of ultrasonic waves, stir and extract the phospholipid-containing lipids in the eyes of tuna. The extraction time is 5 hours, and the extraction temperature is 60°C. During the extraction period, ultrasonic-assisted extraction is performed intermittently every 30 minutes. 100W / cm 2 , the ultrasonic frequency is 25kHz. After the extraction, filter with three layers of gauze and three layers of filter paper respectively, take the filtrate and distill it under reduced pressure at 45°C to collect the lipid fraction, and the eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com