Grinding classification process operation control method based on inverse decoupling active-disturbance-rejection internal model technology

A technology of inverse decoupling and active disturbance rejection, applied in adaptive control, general control system, control/regulation system, etc., can solve the problem of increased system error, decoupling accuracy, robust stability reduction, and complex decoupler. issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0173] The present invention will be described in further detail in conjunction with the accompanying drawings.

[0174] For the convenience of description, the symbols and terms are defined as:

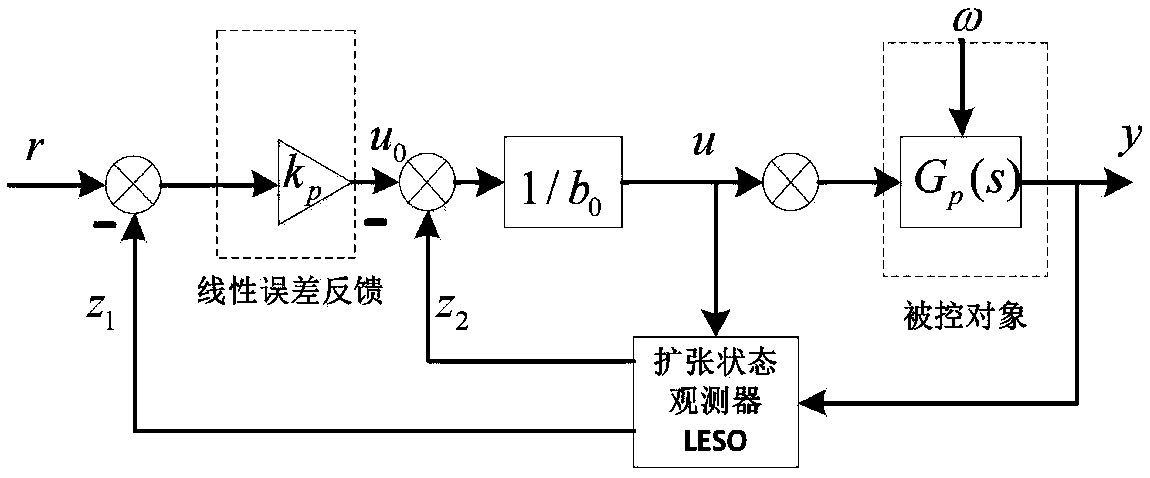

[0175] LADRC Linear Active Disturbance Rejection Controller, English is linearactive dis-turbance rejection controller;

[0176] LESO linear extended state observer, English is linearexte-ndedstate observer;

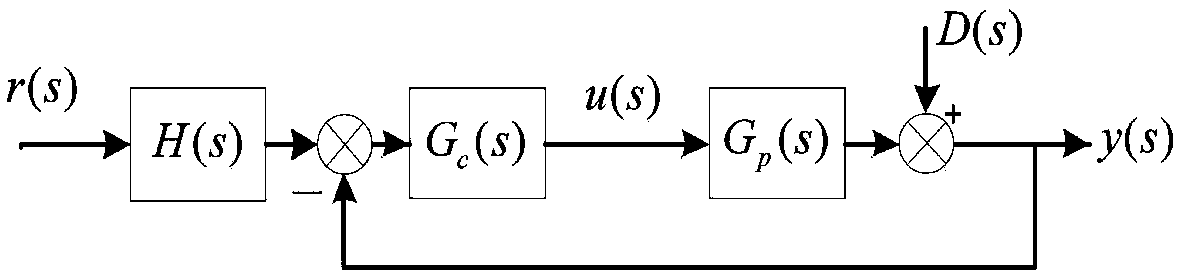

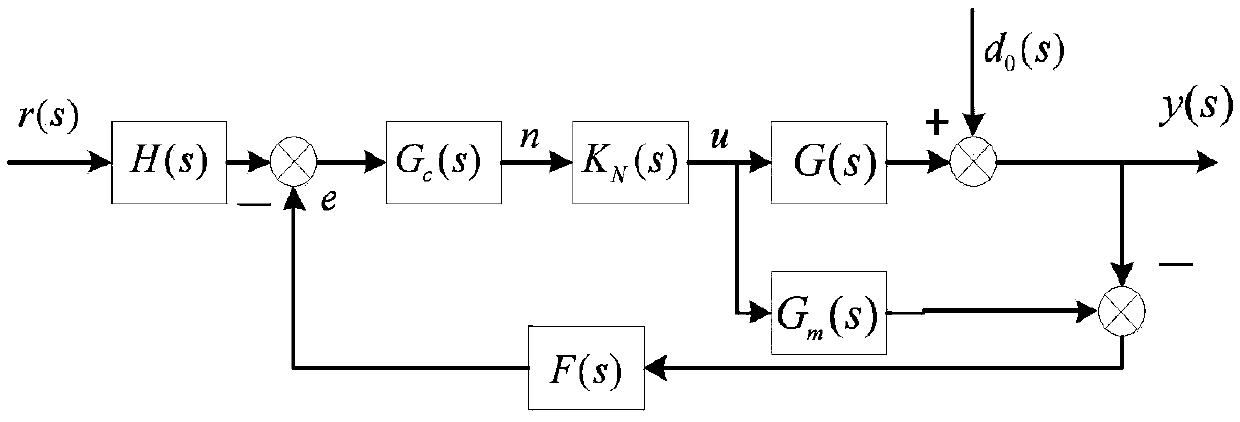

[0177] V-IMC V normative internal model decoupling control method, English is V-norminternalmodel decouplingcontrol method;

[0178] u 1 Grinding and classifying machine added water (m 3 / h) actual value;

[0179] u 2 The actual value of the grinding feed rate (t / h);

[0180] the y 1 Grinding classifier overflow concentration (%) actual value;

[0181] r 1 The expected value of the overflow concentration of the grinding classifier;

[0182] the y 2 The actual value of the amount of sand returned from grinding (t / h);

[0183] r 2 The expected value of the amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com