Composite flexible surface enhanced Raman substrate based on silver nanoparticles and preparation method of substrate

A silver nanoparticle and flexible surface technology, which is applied in the field of composite flexible surface enhanced Raman substrate based on silver nanoparticle and its preparation, can solve the problem that the SERS signal enhancement effect needs to be improved, and achieves easy popularization, simple preparation method, and improved Effects of SERS Signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

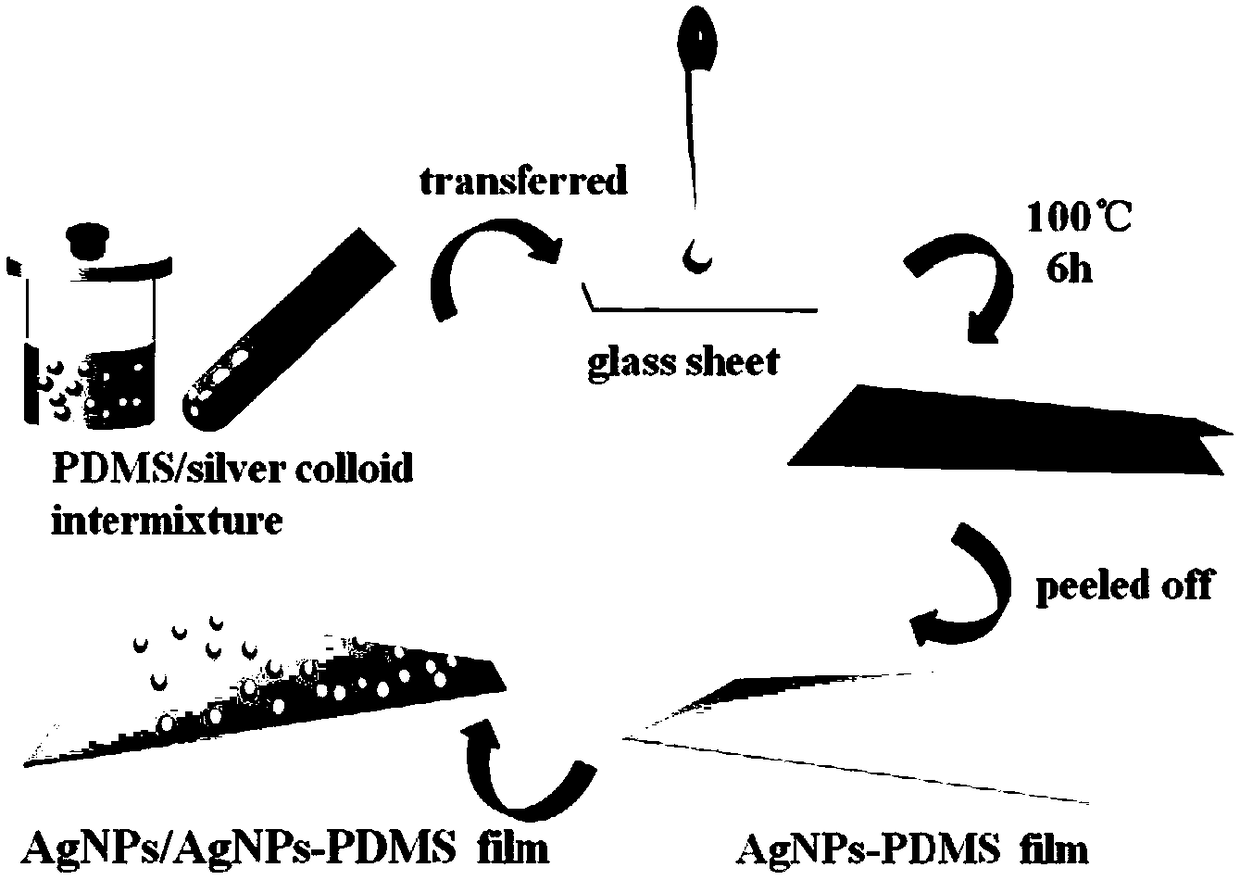

[0040] The invention provides a composite flexible surface-enhanced Raman substrate based on silver nanoparticles and a preparation method thereof, comprising:

[0041] Polydimethylsiloxane-silver colloid composite structure flexible substrate;

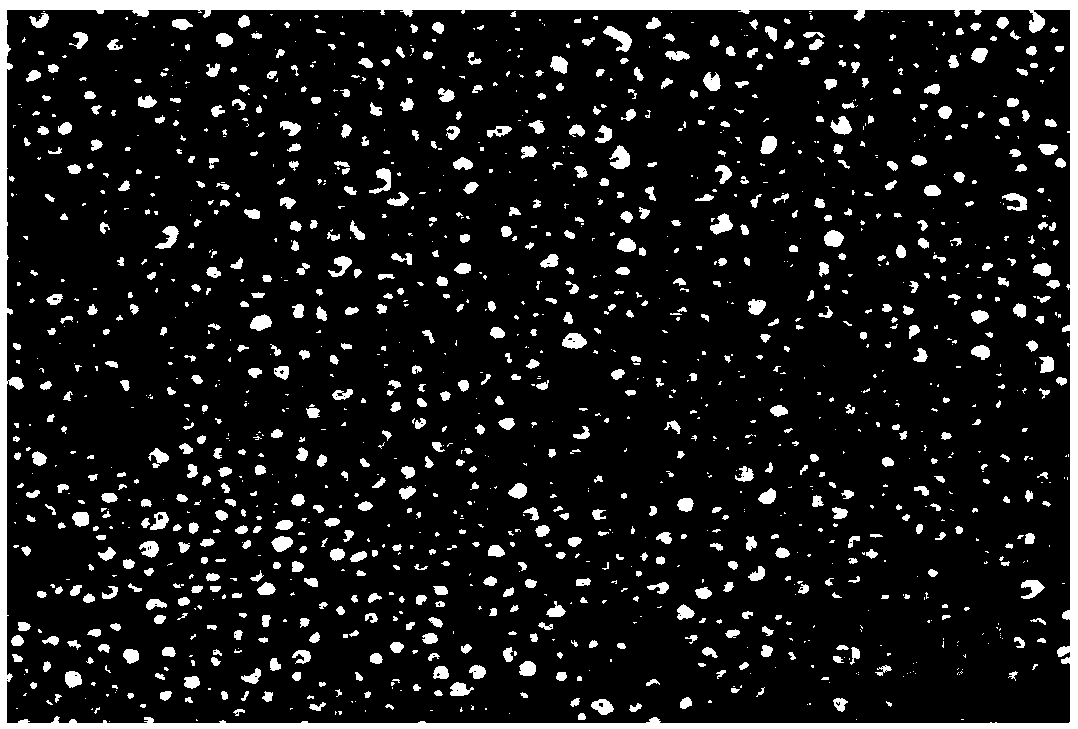

[0042] Silver nanoparticles deposited on polydimethylsiloxane-silver colloid composite structure flexible substrate;

[0043] Among them, the PDMS polymer is mixed with silver colloid, transferred, and cured to form a flexible film, which provides a favorable platform for the probe molecules to directly detect the surface of the object.

[0044] In order to further enhance the surface Raman scattering effect, a layer of silver nanoparticles was transferred on the prepared film by dipping method.

[0045] Compared with the traditional flexible Raman substrate with pure polymer as the template, the polydimethylsiloxane-silver colloid hybrid structure flexible substrate provided by the present invention can provide high-density hotspots w...

Embodiment 1

[0072] 1) Mix 20ML ethylene glycol (C 2 h 6 o 2 , 99.0%) solution was added in the 100ml flask, continued to stir evenly, when heating from room temperature to 70 ℃, add 0.25g polyvinylpyrrolidone (PVP, Mw=55000) in the ethylene glycol solution, when heating to 135 ℃, to Add 0.05g silver nitrate (AgNO 3 ), continue to stir evenly for 1 hour, when the mixed solution turns bright yellow, cool the mixed solution to room temperature and add 60ml of acetone, then centrifuge to obtain a solid precipitate, which is silver nanoparticles, washed 3 times with deionized water , and finally dispersed in 0.5ml deionized water to obtain the colloid of silver nanoparticles

[0073] 2) Mix the liquid PDMS main agent (Sylgard 184 silicone elastomer base) and the curing agent (Sylgard 184 silicone elastomer curing agent) at a mass ratio of 10:1, stir well, remove bubbles by ultrasonic vibration, and prepare a liquid PDMS prepolymer; Mix toluene with the prepared PDMS prepolymer at a volume ...

Embodiment 2

[0083] 20ML ethylene glycol (C2 h 6 o 2 , 99.0%) solution was added in the 100ml flask, continued to stir evenly, when heating from room temperature to 80 ℃, in the ethylene glycol solution, add 0.25g polyvinylpyrrolidone (PVP, Mw=55000), when heating to 130 ℃, to Add 0.05g silver nitrate (AgNO 3 ), continue to stir evenly for 1.5 hours, when the mixed solution turns bright yellow, cool the mixed solution to room temperature and add 60ml of acetone, then centrifuge to obtain a solid precipitate, which is silver nanoparticles, washed 3 times with deionized water , and finally dispersed in 0.8ml deionized water to obtain the colloid of silver nanoparticles

[0084] Mix the liquid PDMS main agent and the curing agent at a mass ratio of 10:1, stir well, remove air bubbles by ultrasonic vibration, and prepare a liquid PDMS prepolymer; mix toluene and the prepared PDMS at a volume ratio of 2:1, and stir thoroughly , ultrasonically oscillate to dilute PDMS; mix the prepared silver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com