Capacity-type metering station with high automation

A volumetric, measuring station technology, applied in the direction of measuring capacity, volume measurement, measuring device, etc., can solve the problems of single function and low measurement accuracy, and achieve the effect of high degree of automation and improved weighing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

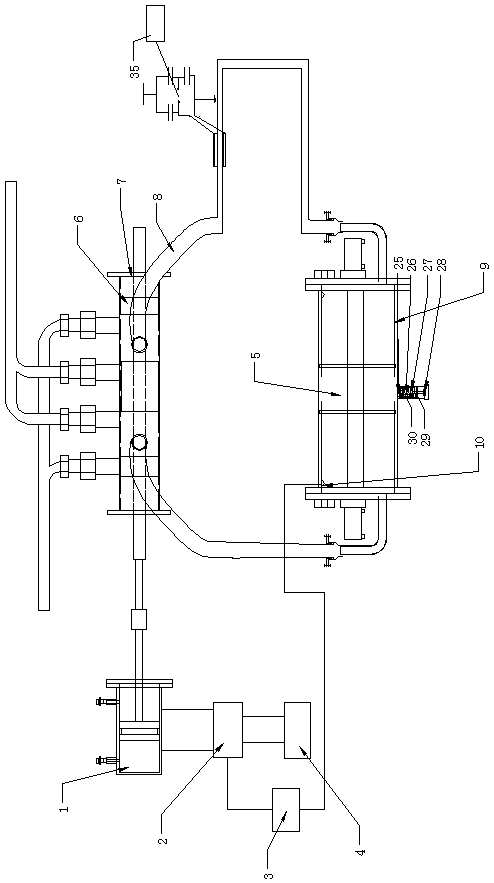

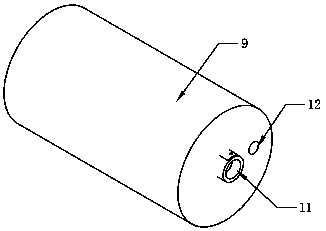

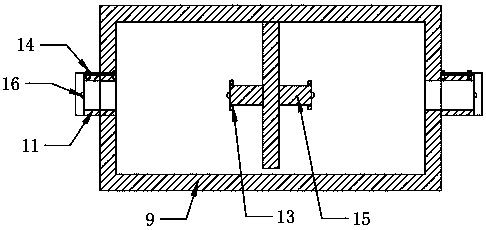

[0037] A volumetric metering station with a high degree of automation, see the accompanying drawings, connected to a standard metal gauge group, including a cylinder connected to a hydraulic control mechanism, the piston end of the cylinder is connected to the piston of the reversing hydraulic cylinder, and the cylinder body of the reversing hydraulic cylinder There are four inlet and outlet joints. There are also oil ports on the cylinder body of the reversing hydraulic cylinder and both ends of the piston of the reversing hydraulic cylinder. The oil ports are connected to the metering pipe 8, and the two metering pipes 8 are connected to the metering hydraulic cylinder. The cavities on both sides of the inner piston, two of the four inlet and outlet joints are connected to the oil inlet or outlet of the standard metal gauge to form the flow rate in different directions of the metering pipeline 8, and there are positions in the metering hydraulic cylinder body The sensor 10 an...

Embodiment 2

[0046] Embodiment 2, the principle of this embodiment is the same as that of Embodiment 1, the specific difference is that the metering hydraulic cylinder is connected in series on the liquid flow circuit pipeline of the volumetric metering station, the inlet end of the liquid flow circuit is connected to the standard metal gauge group, and the outlet end Connected to the metering hydraulic cylinder, the liquid flow circuit is also equipped with a reversing element that drives the liquid in the metering hydraulic cylinder to change direction. There is a gap compensation connection 31 between the two ends of the metering hydraulic cylinder and the liquid flow circuit pipeline. There is a weighing mechanism, the weighing mechanism includes a return spring 30, a cylinder installed on the outside of the spring 30, a large spring tray 25 installed on the top of the spring 30 and a spring adjustment plate 29 installed on the bottom of the spring 30, the spring adjustment plate 29 It ...

Embodiment 3

[0048] Embodiment 3, the principle of this embodiment is the same as that of Embodiment 1, the specific difference is that: the oil-water ratio detection mechanism includes a detection cylinder connected in series to the metering pipeline 8, and in the detection cylinder, a plastic is installed extending from the inlet end to the outlet section. The manufactured metering rod 22 is wound with a winding 21 on the metering rod 22, and after the two ends of the winding 21 pass through the detection cylinder, an external circuit is connected to measure the resistance value of the liquid flow in the metering pipe 8. The external circuit passes through the module After converting the circuit, the digital circuit is connected to output the resistance value, and the oil-water ratio value is output through the controller. The metering rod 22 is coaxially installed with the metering pipe 8, and supporting devices are installed on both sides thereof. In specific implementation, it can also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com