Method for reducing deep peak-shaving oil consumption of 600 MW supercritical "W" flame unit

A supercritical and unit technology, applied in the field of power production, can solve the problem of high peak shaving cost, and achieve the effect of avoiding the loss of starting oil and power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

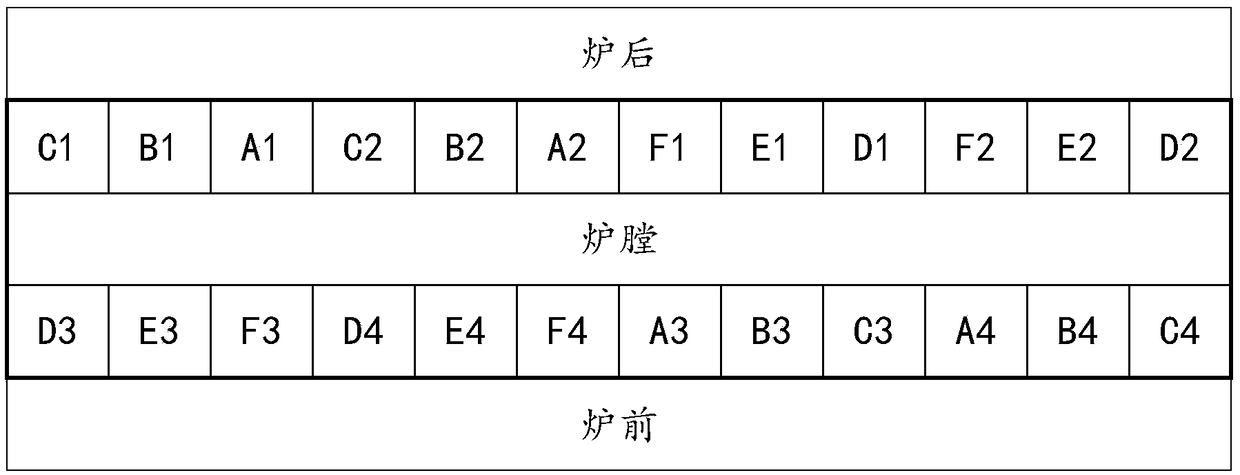

[0031] refer to figure 1 , a method for reducing the fuel consumption of a 600MW supercritical "W" flame unit for deep peak regulation, when the load is lower than 300MW, the method includes,

[0032] Boiler coal quality control, the moisture content in the raw coal should not be greater than 10%, the calorific value of the furnace coal should not be lower than 17MJ / kg, the volatile content should be above 9%, and the ash content should be below 35%;

[0033] Boiler combustion control,

[0034] When the load is lower than 300MW, the thermal load of the boiler is controlled at 50%, the air pressure of the primary fan outlet main pipe is not lower than 6.0Kpa, the total air volume is controlled at 1000-1100t / h, the oxygen content is between 3-4%, and the dynamic separator speed Control at 90-100%, to ensure that the outlet temperature of the powder pipe is great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com