Plane roof self-energy maintenance-free waterproof system and construction method thereof

A construction method and maintenance-free technology, applied to roofs, roof coverings, roofs using flexible materials, etc., can solve the problem that the waterproof effect cannot ensure long-term protection, reduce the service life of the waterproof system, and lack secondary protection of flexible layers, etc. problems, to achieve the effect of preventing water seepage in gaps, improving waterproof ability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: The present embodiment will be described in further detail below in conjunction with the accompanying drawings.

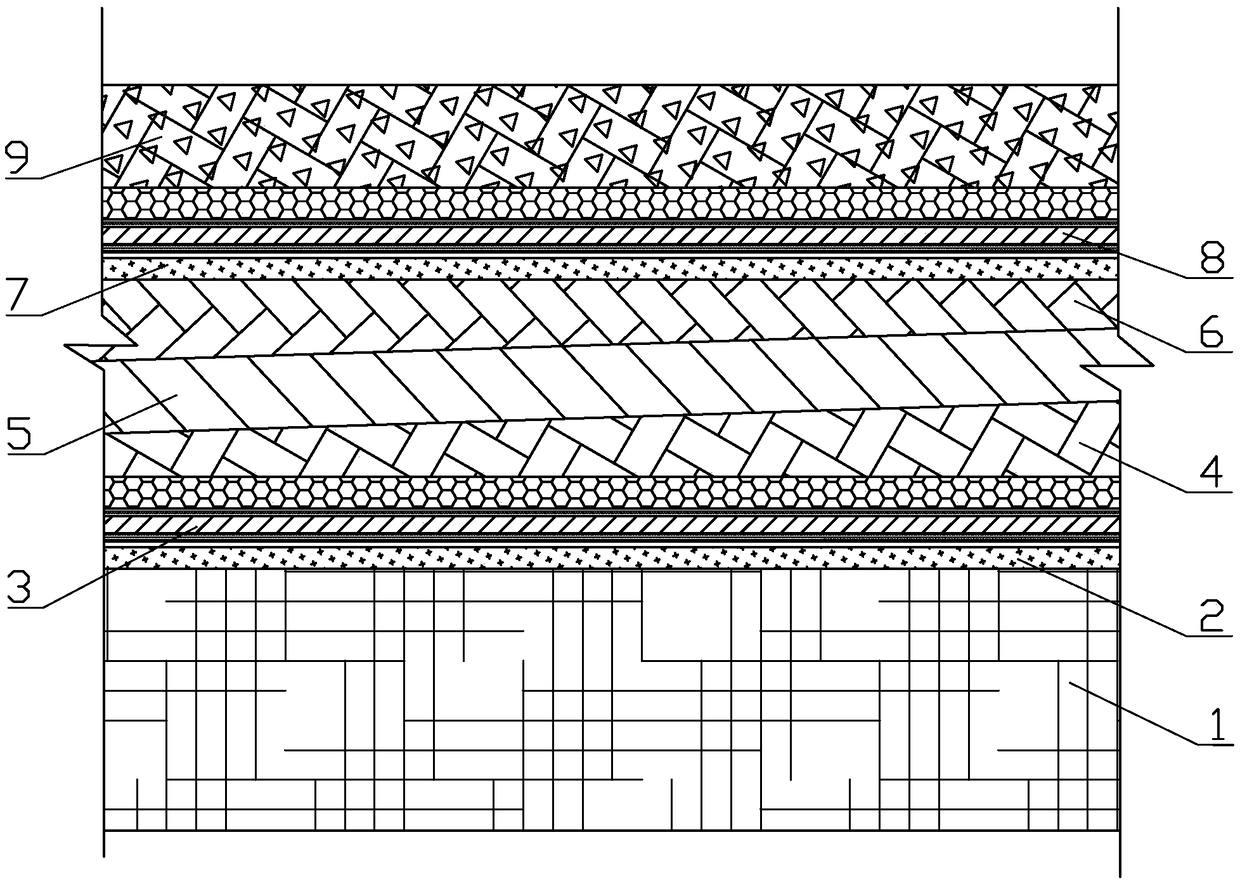

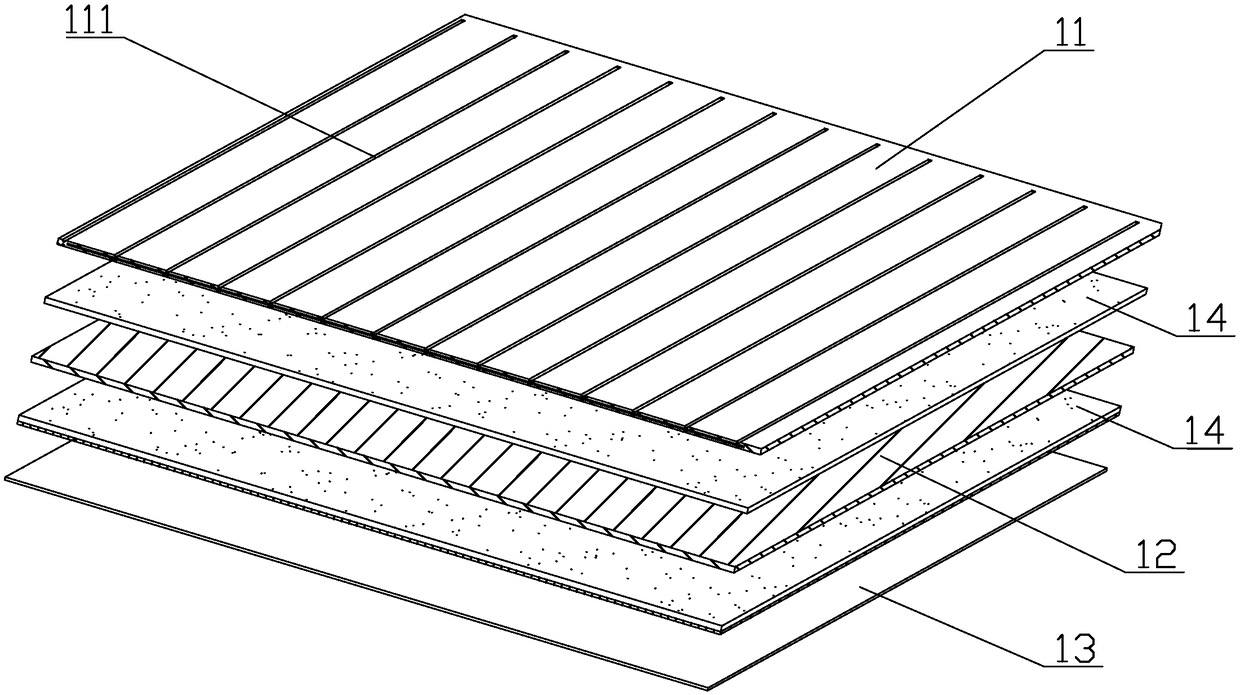

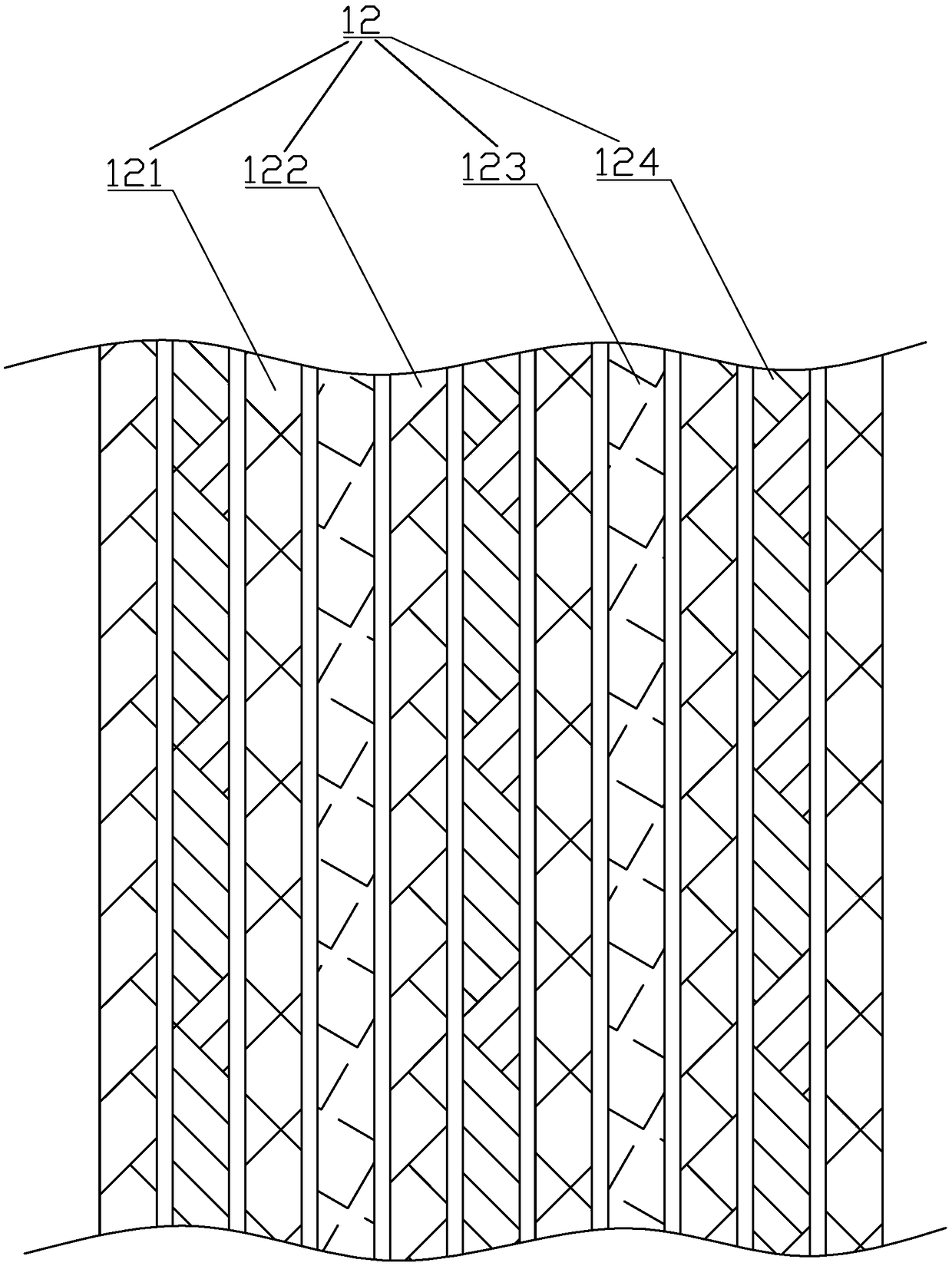

[0054] Such as figure 1 As shown, a self-energy maintenance-free waterproof system for flat roofs includes a reinforced concrete base, on which the first paint layer, the first coil layer, the concrete slope layer, the thermal insulation layer, and the cement mortar leveling layer are sequentially arranged. layer, second paint layer, second membrane layer and fine stone concrete protective layer. Among them, both the first paint layer and the second paint layer are coated with non-cured rubber asphalt waterproof coating. The addition of resin, on the one hand, brings good elasticity and stretchability to the coating, making the coating more adaptable to the subsequent changes and development of cracks, and realizes the function of self-healing; on the other hand, the tackifying resin has high stability and high viscosity , can endow the coati...

Embodiment 2

[0072] Embodiment 2: A construction method of a flat roof self-energy maintenance-free waterproof system, comprising the following steps:

[0073] S1 base treatment: clean the surface of the base, fill in the defects, and air dry;

[0074] S2 Brushing the paint: heating the non-curing rubber asphalt waterproof paint to the state of construction, spraying and scraping the paint, and completely covering the surface of the base layer with the paint to form the first paint layer;

[0075] S3 node strengthening: check the surface of the first paint layer, and fill the irregular or uneven corners of the roof with the cut polymer self-adhesive membrane, so that the polymer self-adhesive membrane is bonded to the first paint layer;

[0076] S4 laying the first layer of coiled material: before the non-curing rubber asphalt waterproof coating is cooled, the polymer self-adhesive coiled material is laid on the surface of the first coating layer, and the ribs between the adjacent polymeri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com