Soaking device with fast soaking speed for silk product

A fast, silk technology, applied in liquid/gas/vapor processing transmission, equipment configuration for processing textile materials, processing textile material containers, etc., can solve the problems of long silk dyeing processing time, slow soaking speed, etc. Faster, more efficient, more practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

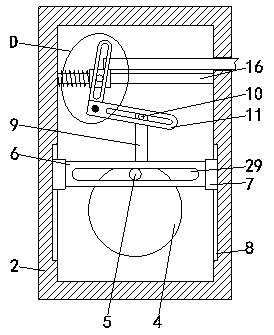

Image

Examples

Embodiment 2

[0038] Embodiment 2: The difference from Embodiment 1 is that the pressing plate mechanism 22 includes a first fixed plate 2201, and both sides of the rear side of the bottom of the first fixed plate 2201 are fixedly connected with a second fixed rod 2202, and the bottom of the second fixed rod 2202 It is fixedly connected with the rear side of the top of the housing 1, and both sides of the front side of the bottom of the first fixed plate 2201 are fixedly connected with a multi-stage telescopic cylinder 2203, and the bottom of the multi-stage telescopic cylinder 2203 is fixedly connected with a third fixed block 2204. The bottom of the fixed block 2204 is fixedly connected with the fifth fixed column 2205, the front side and the rear side of the surface of the fifth fixed column 2205 are both movably connected with the second fixed plate 2206, and the bottom of the second fixed plate 2206 is fixedly connected with the leaking plate 2207, The drain plate 2207 is used in conjun...

Embodiment 3

[0039] Embodiment 3: The difference from Embodiment 1 is that the anti-blocking mechanism 24 includes a fixed pipe 2401, and the left side of the fixed pipe 2401 surface is fixedly connected with a first sealing plate 2402, and the left side of the first sealing plate 2402 is connected to the discharge pipe 23 The right side of the first sealing plate 2402 is movably connected, the top on the right side of the first sealing plate 2402 is movably connected to the right side of the discharge pipe 23 top through a hinge, the inside of the fixed pipe 2401 is slidingly connected with the second sealing plate 2403, and the second sealing plate 2403 The right side is fixedly connected with a third fixed rod 2404, the right side of the third fixed rod 2404 runs through the fixed pipe 2401 and extends to the right side of the fixed pipe 2401, the right side of the third fixed rod 2404 is fixedly connected with a pressing plate 2405, by setting The anti-blocking mechanism 24, the dischar...

Embodiment 4

[0040] Embodiment 4: The difference from Embodiment 2 is that both sides of the third fixed block 2204 are fixedly connected with the first return spring 26, and the side of the first return spring 26 away from the third fixed block 2204 is fixedly connected with the fourth fixed block. Block 27, the bottom of the fourth fixed block 27 is fixedly connected with the top of the second fixed plate 2206, and the inside of the second fixed plate 2206 is provided with a second chute 28 used in conjunction with the fifth fixed column 2205, by setting the first return spring 26. The fourth fixed block 27 and the second chute 28, in order to move, the devices on the market will leave a large gap, which will easily cause the silk to float out from the side, thus failing to achieve the purpose of pressing down on the silk. However, this structure It can move together with the cleaning box 19 to avoid the structure from being stuck, facilitate the use of the user, and effectively prevent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com