Preparation method of wear-resisting polyether-ether-ketone composite material filled and reinforced by calcium carbonate crystal whisker-vermiculite

A technology of calcium carbonate whiskers and polyetheretherketone, which is applied in the field of mechanical parts materials, can solve the problems of high friction coefficient of polyetheretherketone and harsh use requirements, and achieves improved interface bonding force, improved wear resistance, and improved shearing performance. Effect of Shear Strength and Storage Modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

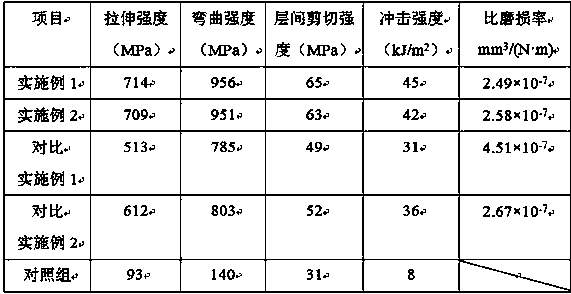

Examples

Embodiment 1

[0025] A preparation method of a calcium carbonate whisker-vermiculite filled reinforced wear-resistant polyetheretherketone composite material, characterized in that it comprises the following steps:

[0026] (1) Carbon fiber surface polymer coating:

[0027] Dissolve 1 part of sulfonated polyetheretherketone in dimethylformamide to make a coating solution with a concentration of 4g / L, dip the activated carbon fiber in the coating solution for 1 hour, take it out, and wait until the solvent evaporates , placed in a vacuum oven at 120-125°C for drying;

[0028] (2) Organic intercalation treatment of layered vermiculite:

[0029] Add 3 parts of distilled water, 3 parts of sodium chloride, and 500 parts of hydrochloric acid to 1 part of layered vermiculite, stir in a water bath at 80-83°C for 4 hours, filter and wash with water until there is no Cl - , mix with distilled water, add 1 part of organic intercalation agent hexadecyltrimethylammonium bromide, stir in 80-83℃ water b...

Embodiment 2

[0038] A preparation method of a calcium carbonate whisker-vermiculite filled reinforced wear-resistant polyetheretherketone composite material, characterized in that it comprises the following steps:

[0039] (1) Carbon fiber surface polymer coating:

[0040] Dissolve 2 parts of sulfonated polyetheretherketone in dimethylformamide to prepare a coating solution with a concentration of 6g / L. Immerse the activated carbon fiber in the coating solution for 2 hours, take it out, and wait for the solvent to evaporate , placed in a vacuum oven at 120-125°C for drying;

[0041] (2) Organic intercalation treatment of layered vermiculite:

[0042] Add 6 parts of distilled water, 6 parts of sodium chloride, and 600 parts of hydrochloric acid to 2 parts of layered vermiculite, stir in a water bath at 80-83°C for 5 hours, filter and wash with water until there is no Cl - , mixed with distilled water, added 2 parts of organic intercalation agent hexadecyltrimethylammonium bromide, stirred i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com