High-quality modifier for PVC (Polyvinyl Chloride) processing and preparation process thereof

A modifier and high-quality technology, which is applied in the field of plastic processing aids, can solve the problems of reduced tensile strength, elongation, tear strength and other indicators, affecting the physical and mechanical properties of PVC materials, and difficult processing, etc., to achieve structural High stability, strong reactivity, and overall quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

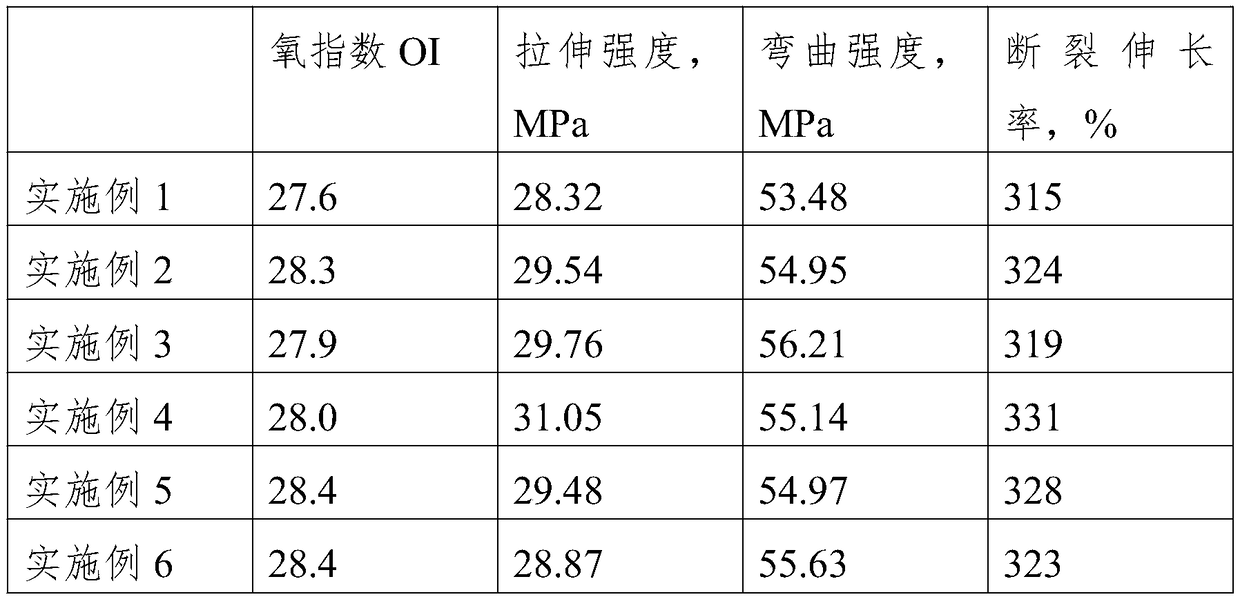

Examples

Embodiment 1

[0022] A high-quality modifying and modifying agent for PVC processing, including component A, component B, and additive C. The component A includes the following raw materials: brucite, diatomite-loaded heteropolyacid, composite surface active The component B includes the following raw materials: polyimide, thermoplastic phenolic resin, cellulose acetate propionate; the additive C includes a dispersant and a lubricant; the mass ratio of the component A to the component B The ratio is 1:1, and the mass of additive C is 3% of the total mass of component A and component B.

[0023] Component A also includes magnesium borate whiskers, and the parts by weight of the raw materials in component A are as follows: 10 parts of brucite, 12 parts of diatomite-supported heteropolyacid, 0.5 parts of composite surfactant, 2 parts of magnesium borate whiskers share. Among them, the heteropolyacid in the diatomite-loaded heteropolyacid is selected from the Keggin type heteropolyacid containi...

Embodiment 2

[0031] A high-quality modifying and modifying agent for PVC processing, including component A, component B, and additive C. The component A includes the following raw materials: brucite, diatomite-loaded heteropolyacid, composite surface active The component B includes the following raw materials: polyimide, thermoplastic phenolic resin, cellulose acetate propionate; the additive C includes a dispersant and a lubricant; the mass ratio of the component A to the component B The ratio is 1:1.5, and the mass of additive C is 7% of the total mass of component A and component B.

[0032]Component A also includes magnesium borate whiskers, and the parts by weight of the raw materials in component A are as follows: 15 parts of brucite, 10 parts of diatomite-loaded heteropoly, 1.2 parts of composite surfactant, and 0.5 parts of magnesium borate whiskers . Among them, the heteropolyacid in the diatomite-loaded heteropolyacid is selected from the Keggin type heteropolyacid containing tu...

Embodiment 3

[0037] A high-quality modifying and modifying agent for PVC processing, including component A, component B, and additive C. The component A includes the following raw materials: brucite, diatomite-loaded heteropolyacid, composite surface active The component B includes the following raw materials: polyimide, thermoplastic phenolic resin, cellulose acetate propionate; the additive C includes a dispersant and a lubricant; the mass ratio of the component A to the component B The ratio is 1:1.2, and the mass of additive C is 6% of the total mass of component A and component B.

[0038] Component A also includes magnesium borate whiskers, and the parts by weight of the raw materials in component A are as follows: 15 parts of brucite, 5 parts of diatomite-supported heteropolyacid, 1.5 parts of composite surfactant, 2.5 parts of magnesium borate whiskers share. Among them, the heteropolyacid in the diatomite-loaded heteropolyacid is selected from the Keggin type heteropolyacid conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com