Low-cost method for preparing high-purity linaclotide

A linaclotide and high-purity technology, which is applied in the field of low-cost preparation of high-purity linaclotide, can solve the problems of difficult scale-up production, high cost, complicated process, etc., and achieves low price, improved product yield, and reduced volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the synthesis of Fmoc-Tyr (tBu)-CTC resin

[0027] Take 500 g of CTC resin with a substitution degree of 0.5 mmol / g, and add DMF to swell the resin. Take 0.5mol Fmoc-Tyr(tBu)-OH, dissolve it with an appropriate amount of DMF, add it to the above resin, stir well, then add 0.75mol DIPEA, stir for 3 hours, filter the reaction solution, and wash it with DMF for 3 times , and washed 3 times with DCM to obtain Fmoc-Tyr(tBu)-CTC resin. Its substitution value is 0.4 mmol / g.

Embodiment 2

[0028] Embodiment 2: Preparation of linaclotide resin

[0029] Take 0.15 mol of the Fmoc-Tyr(tBu)-CTC resin of Example 1, deprotect it with 20% PIP / DMF solution for 20 minutes, wash and filter to obtain the H-Tyr(tBu)-CTC resin from which Fmoc has been removed.

[0030] Take 0.45mol Fmoc-Cys(Trt)-OH, dissolve it with an appropriate amount of DMF, and add it to the reactor equipped with the above-mentioned H-Tyr(tBu)-CTC resin, and take another 0.45mol HBTU and 0.45mol DIPEA, and add them slowly Into the above-mentioned reactor which is blown with nitrogen. Coupling reaction for 30 to 150 minutes, the end point of the reaction is determined by the ninhydrin method, washed and filtered, then deprotected with 20% PIP / DMF solution for 20 minutes, washed and filtered to obtain H-Cys(Trt)-Tyr(tBu) - CTC resin.

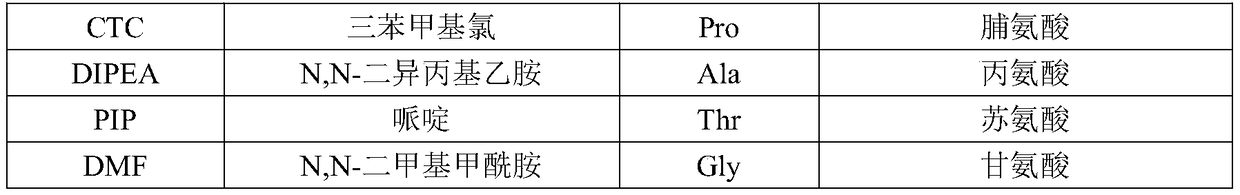

[0031] In the same way as above, the remaining protected amino acids in Table 1 were sequentially inserted to obtain the linaclotide peptide resin:

[0032] H-Cys(Trt)-Cy...

Embodiment 3

[0036] Example 3: Preparation of crude linaclotide linear peptide

[0037] The linaclotide resin obtained in Example 2 was taken, washed after cleavage, and dried under vacuum to constant weight to obtain 201 g of linear linaclotide crude product with a purity of 76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com