A kind of mechanochromic material and preparation method thereof

A technology of color-changing and compounding, which is applied in the fields of color-changing fluorescent materials, analytical materials, material excitation analysis, etc., which can solve the problems of difficult realization, unclear color-changing mechanism, and few types of mechanochromic materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Compound B 1 Synthesis of: Compound B 1 The synthetic route is attached figure 1 shown.

[0039]

[0040] 1) Synthesis of Compound 1: Put 30mmol of 4-bromopyridinecarbaldehyde and 15mmol of indolinone into a reaction flask, add 100ml of dry toluene, heat to reflux for 10h, then cool the reaction system, spin the solvent, and the residue Silica gel column chromatography (petroleum ether: ethyl acetate ratio of 5:1) gave a light yellow crude product, which was recrystallized in a mixed solvent of petroleum ether ethyl acetate to give a light yellow white solid with a yield of 54%.

[0041]

[0042] 2) Synthesis of compound 2: Add 20 mmol of compound 1 to the reaction flask, add 100 ml of tetrahydrofuran, add 1.2 equivalents of triphenylamine borate and catalyst 1,1'-bis(diphenylphosphine) according to the molar amount of compound 1 Ferrocene Nickel Dichloride (Ni(dpppf)Cl 2 ), heated to reflux overnight in a nitrogen atmosphere. Then the reaction system was coo...

Embodiment 2

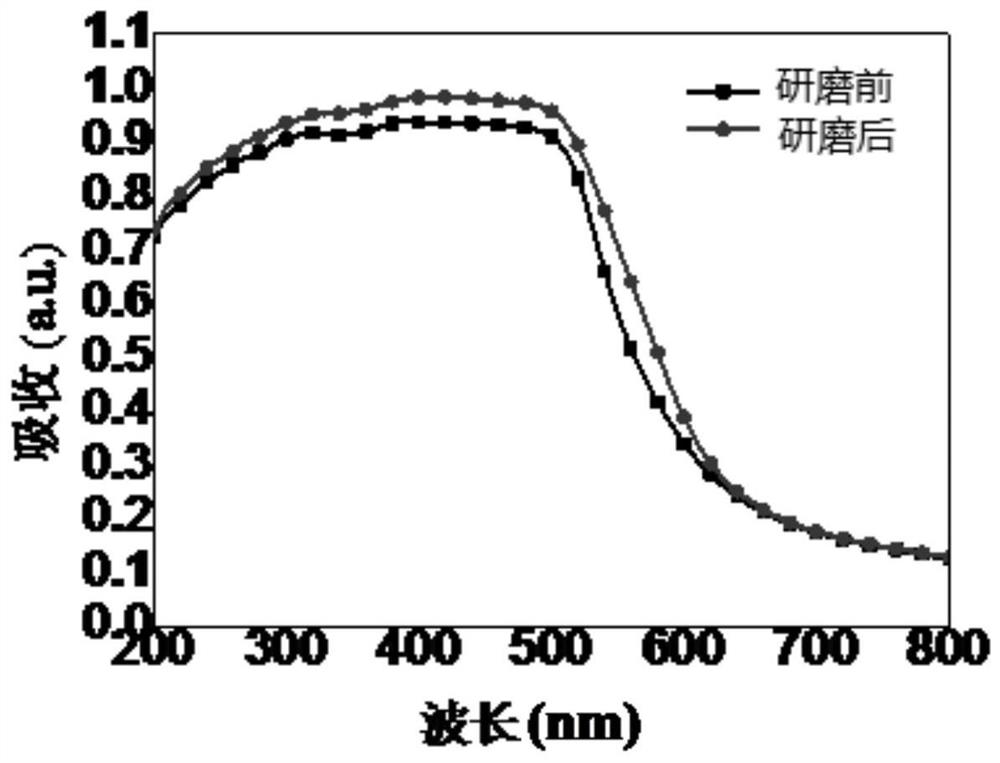

[0047] (1) Our compound B 1 Solid UV test before and after milling, compound B 1 Solid UV spectra before and after grinding, as attached figure 2 As shown, from the figure we can see that compound B 1 There is little change in solid UV before and after grinding. by compound B 1 The solid fluorescence before and after grinding was tested and calculated to obtain compound B 1 The solid fluorescence quantum efficiency changed from 1.9 to 1.8 before and after grinding.

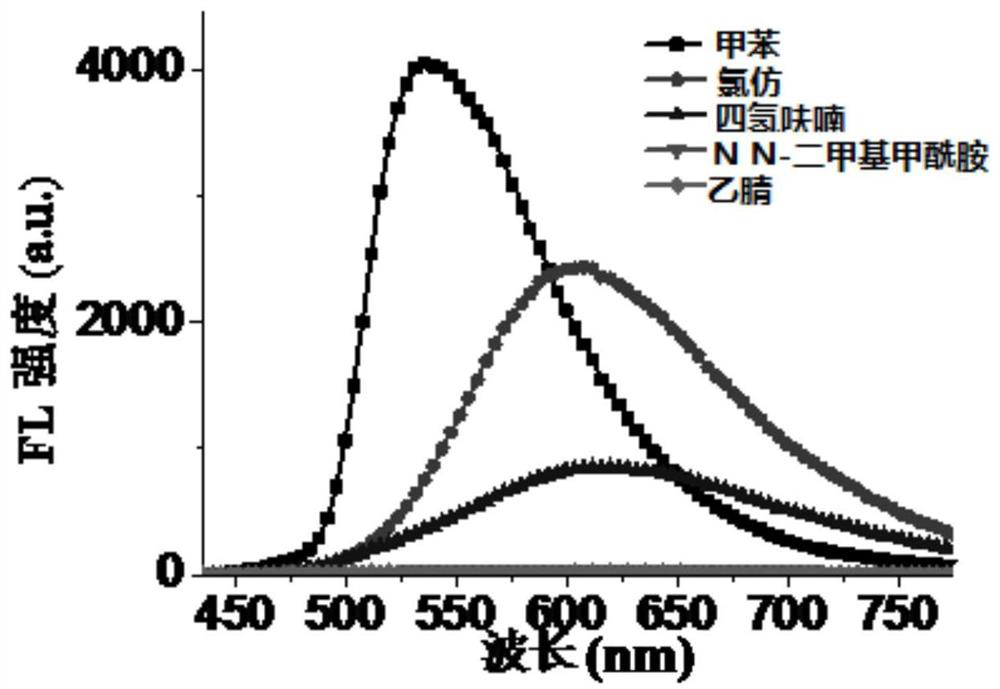

[0048] (2) In order to detect the grinding and discoloration characteristics of the luminescent material of the present invention, compound B 1 Put it into a mortar, grind for 2-3 minutes, and use 420nm as the excitation wavelength to perform solid-state fluorescence spectrum detection. The results are shown in the attached image 3 shown. It can be seen from the figure that after grinding, compound B 1 The maximum absorption peak shifted red from 610nm to 653nm, and the corresponding color changed from o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com