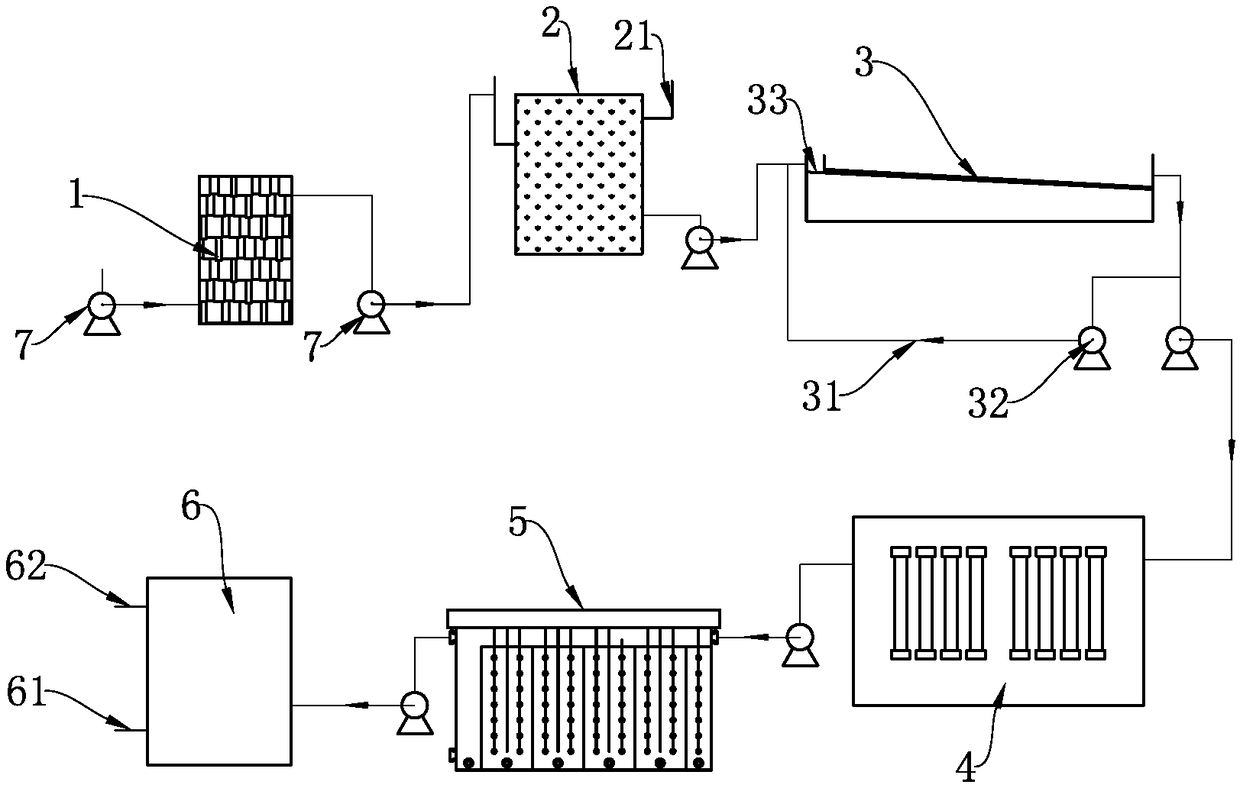

Multi-stage coupled zero-discharge water treatment system for BDP wastewater

A water treatment system and zero discharge technology, applied in the direction of water/sewage multi-stage treatment, water/sewage treatment, special compound water treatment, etc., can solve problems such as difficult treatment, high salinity, and increased difficulty of treatment, and achieve in-depth Strong processing capacity, improved processing efficiency, and strong adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Sand filter: The BDP wastewater is firstly passed through a sand filter to initially remove large particles and colloidal substances in the wastewater. The sand filter used in the sand filter is quartz sand with a particle size of 1-3 mm.

[0046] (2) Air flotation tank: the BDP waste water is passed through the air flotation tank, and the unreacted solvent toluene is separated by air flotation, and the solid particle suspension in the water is further removed at the same time. The sewage treatment capacity of the air flotation tank is 9m 3 / h.

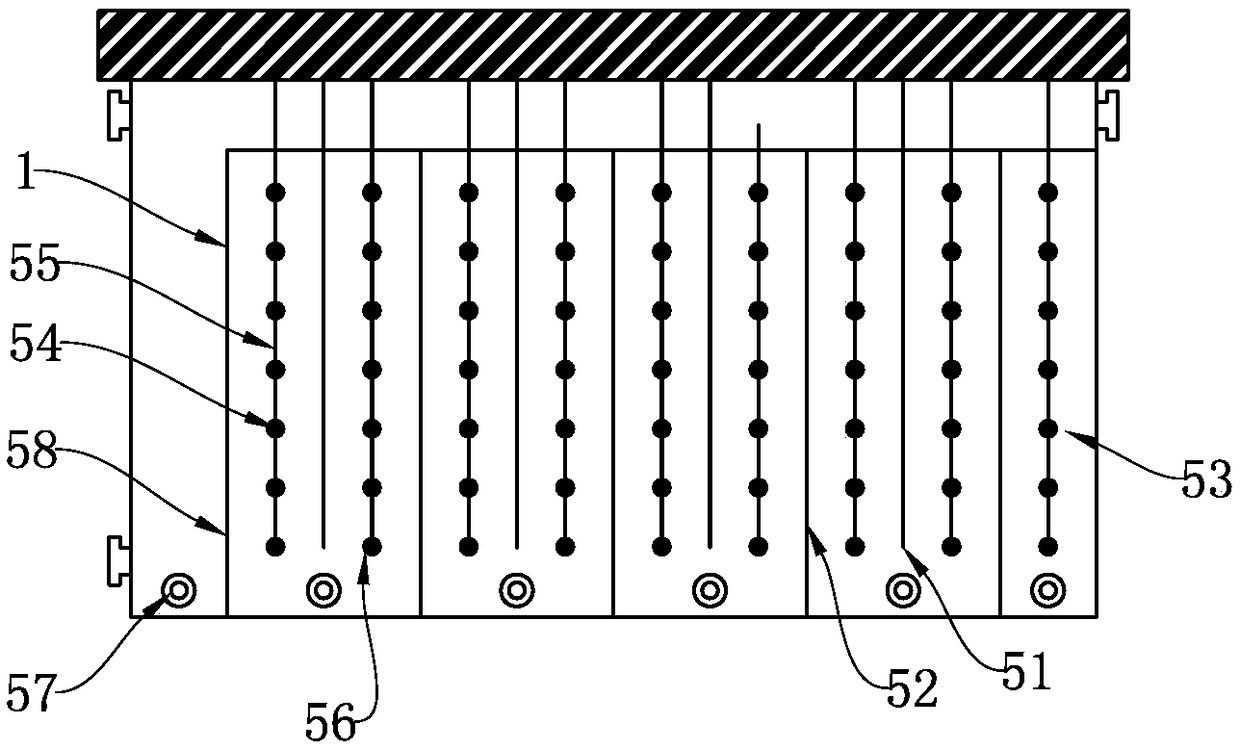

[0047] (3) Visible light catalytic reaction tank: the waste water after air flotation separation is passed through the visible light catalytic reaction tank, and the bottom of the visible light catalytic reaction tank is inclined 12° downward along the water flow direction; the water outlet of the visible light catalytic reaction tank and A return pipe is provided between the water inlets, and a return pump is provided on t...

Embodiment 2

[0052] The nano-Au / TiO 2 The loading method of the catalyst is the multiple impregnation and pulling method, and the number of leaching and loading is 8 times. After each impregnation, it is dried at a temperature of 70°C before continuing to the next loading; after loading, it is calcined for 2 hours under an inert atmosphere protected by nitrogen, and the The temperature is 400°C.

[0053] The nano-Au / TiO 2 The preparation method of the catalyst is a photochemical reduction deposition method, which includes the following steps: first, water and isopropanol are mixed in a ratio of 1:1 and placed in a photochemical reaction bottle, and then the concentration of 3g / L nano-TiO 2 Slowly add the aqueous phase dispersion into the photochemical reaction bottle, fully stir and mix evenly, seal the photochemical reaction bottle, pass in argon gas for deoxygenation for 1 hour; then irradiate under a 500W long-arc high-pressure mercury lamp. mol / L of HAuCl 4 The solution was slowly a...

Embodiment 3

[0055] The loaded nano TiO 2 The preparation method of the molecular sieve pellets is as follows: 3.6g Ti(SO 4 ) 2 Dissolve in 150ml distilled water, stir rapidly until completely dissolved, Ti(SO 4 ) 2 Aqueous solution is transferred in the three-necked flask, takes by weighing 5g molecular sieves and joins in the three-necked flask, stirs and makes molecular sieve to Ti(SO 4 ) 2 Fully adsorb and mix; then dissolve 1.35g urea in 50ml distilled water, stir until completely dissolved, then slowly drop the aqueous solution of urea into the Ti(SO 4 ) 2 In the three-necked flask of the mixed solution with molecular sieve, after the dropwise addition of the urea solution, heat to 75°C and stir for 4 hours, then transfer the mixed solution to a high-pressure reactor, conduct a hydrothermal reaction at 90°C for 24 hours, and pour out the solution after the reaction is completed and cooled to room temperature , washed several times, dried, and calcined at 450°C for 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com