Ionic internal mixer

An internal mixer and ion-type technology, which is applied in the field of ion-type mixing internal mixers, can solve the problems of reduced production efficiency, single function, and environmental pollution, and achieve the effects of improving production efficiency, optimizing the working environment, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

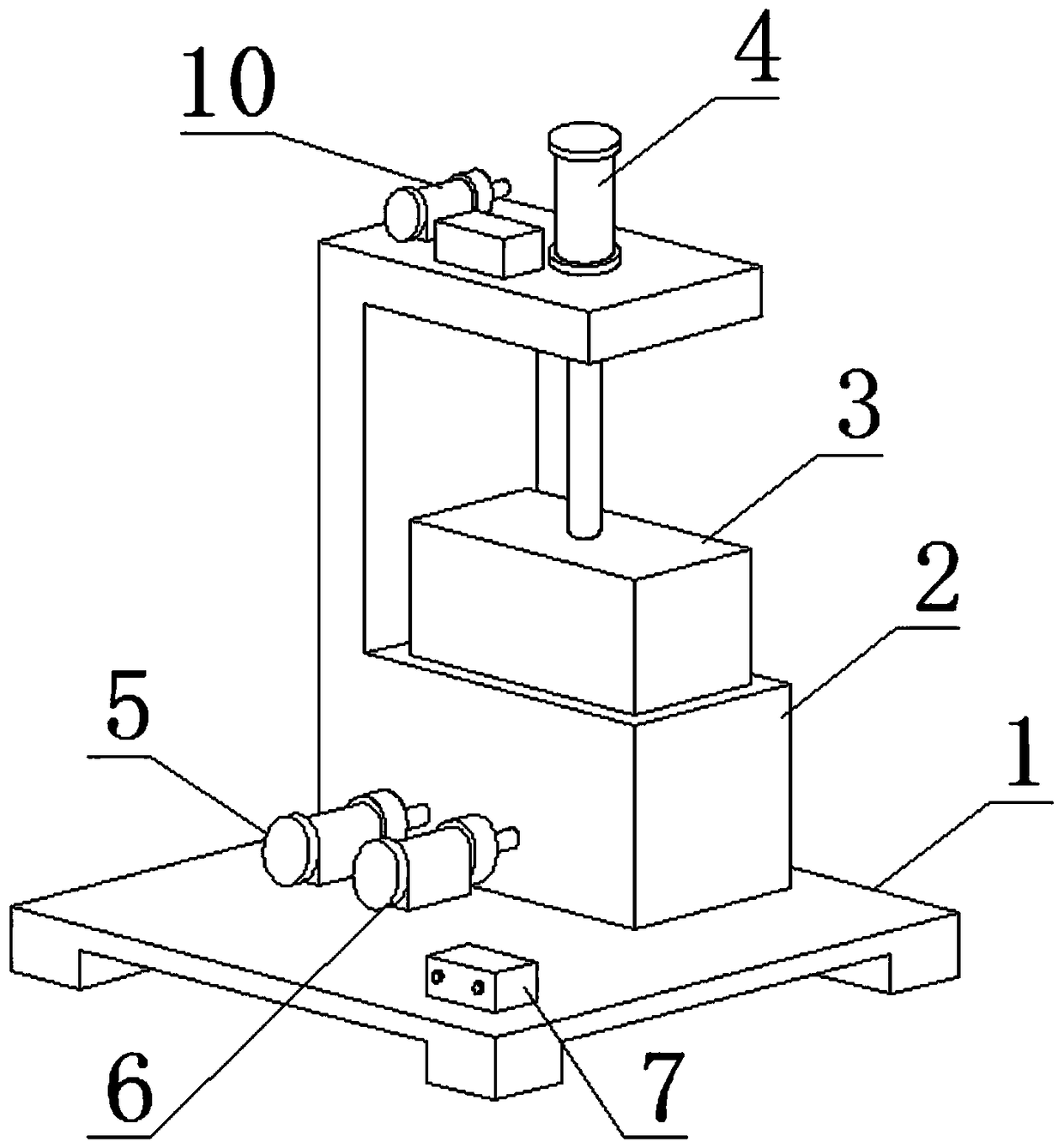

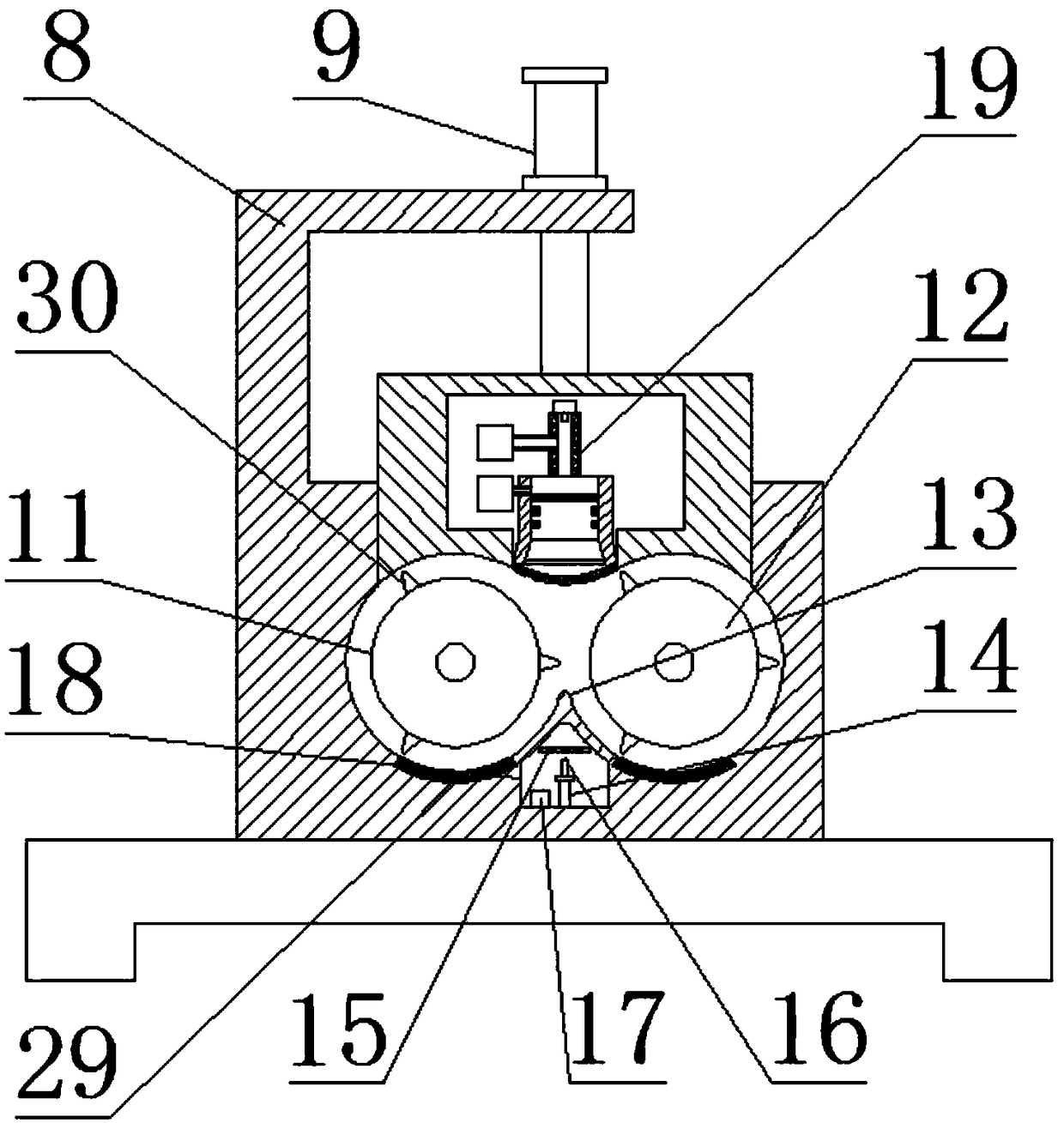

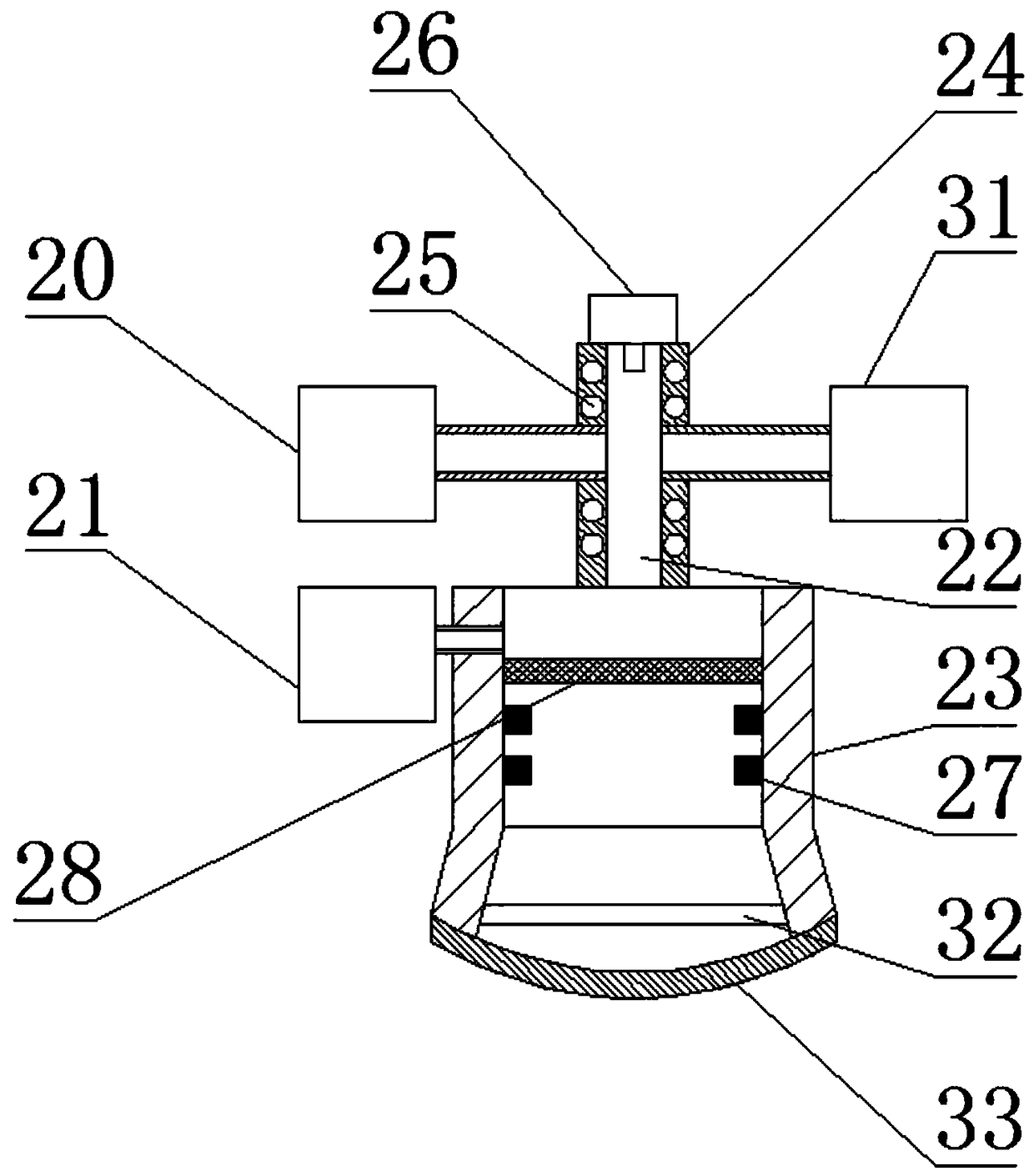

[0022] Examples, see Figure 1~3 , the present invention provides a technical solution:

[0023] An ionic mixing internal mixer, comprising a chassis 1, a banburying chamber 2, a pressure block 3, a hydraulic system 4, a motor unit 5, a motor unit 2 6 and a control box 7, the banburying chamber 2 Set on the bottom frame 1, a support frame 8 is provided on one side of the mixing chamber 2, the hydraulic system 4 includes a hydraulic cylinder 9, a hydraulic motor group 10 and a hydraulic oil tank, and the hydraulic cylinder 9 is set on the support frame 8, one end of the pressure block 3 is connected to the hydraulic cylinder 9, and the other end of the pressure block 3 is sleeved in the banburying chamber 2, and the banburying chamber 2 is provided with a banburying chamber. The mixing chamber is provided with extrusion wheel one 11, extrusion wheel two 12, shear block 13 and cathode arc plate 29. One end connection of the two motor units 6 is arranged on one side of the banb...

Embodiment approach

[0024] As a preferred embodiment of the present invention, the first extrusion wheel 11 and the second extrusion wheel 12 are provided with special-shaped blocks 30 .

[0025] As a preferred embodiment of the present invention, the shear block 13 is provided with wear-resistant threads.

[0026] As a preferred embodiment of the present invention, the hydraulic motor assembly 10 includes an electric motor and a hydraulic motor, and the hydraulic motor is connected to the hydraulic oil tank and the hydraulic oil cylinder 9 through pipelines.

[0027] As a preferred embodiment of the present invention, the control buttons include start button, oil cylinder button, extrusion wheel one button, extrusion wheel two button, propellant button, pressurization button, resistance wire button, discharge button, laser light button and the laser frequency converter knob, the control button is connected to the propellant device 20, the main propellant device 21, the pressurizing device 31, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com