Blind hole boring cutter assembly

A boring tool and component technology, applied in the field of blind hole boring tool components, can solve the problems of increasing chip removal, easy wear of alloys, and chattering of tool bars, and achieves the effects of reducing scrap rate, reducing friction and eliminating vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0051] Refer to attached Figure 4 As shown, as a further improvement of the above-mentioned embodiment, in this embodiment, the above-mentioned support block 5 is changed to a screw, that is, several screw holes are opened on the outer periphery of the rotating body 2, and the screw is threadedly connected to the screw holes. Specifically, the length of the screw is 40mm-120mm. Generally, in order to reduce the weight, the volume of the rotating body 2 is small, and the distance between the rotating body 2 and the inside of the hole is relatively large, so the length of the screw can also be adjusted accordingly.

[0052] In this embodiment, a lock nut 10 is added outside the screw hole, and the screw rod is locked through the lock nut 10, so as to avoid the shaking of the screw rod during rotation, so that it is locked on the outer periphery of the rotating body 2, and the connection stability is improved. .

[0053] In this example, refer to the attached Figure 5 As sho...

Embodiment 3

[0057] Refer to attached image 3 As shown, as a further supplement to the above-mentioned embodiment, in this embodiment, the main body 1 of the cutter head is selected to be a square or disc-shaped structure. Refer to attached Figure 6 Shown, select disc-shaped cutter head main body 1 now, offer chute 13 on cutter head main body 1, cutter head 6 is placed in chute 13, two cutter heads 6 are placed in one chute 13.

[0058] At least two screws 14 are arranged on the sides of each chute 13 , and the screws 14 abut against the cutter head 6 , and the length of the cutter head 6 can be adjusted by unscrewing or locking the screws 14 . For example, when the length needs to be adjusted, the screw 14 is unscrewed, and now the cutter head 6 moves freely in the chute 13, adjusted to a suitable position, then the screw 14 is tightened, and the cutter head 6 is locked in the chute.

[0059] Refer to attached image 3 As shown, in the present embodiment, in order to realize the cool...

Embodiment 4

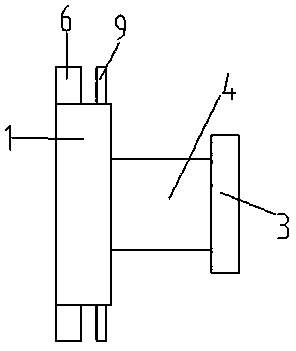

[0063] As a further improvement of any of the above embodiments, refer to the attached image 3 As shown, in this embodiment, the rotating body 2 adopts a bearing, specifically a tapered roller bearing, and a flange is arranged outside the bearing, and the flange is fixedly connected with the bearing through a nut, etc. The nut is provided with a sealing ring 17. When the rotating body 2 rotates, the additional sealing ring 17 prevents foreign matters from entering the bearing and reduces the service life of the bearing. During installation, the whole is connected with the flange of the tool holder through pin positioning and thread fastening.

[0064] When in use, the bearing and the pipe 7 rotate in the same direction and at the same speed, while the cutter head body 1 and the cutter bar 3 only move horizontally instead of circularly, which reduces the wear on the support block 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com