3D printer provided with gradient powder feeding system

A 3D printer and powder supply technology, which is applied in the field of additive manufacturing, can solve the problems of complicated powder mixing and uniform distribution steps, inability to guarantee volume ratio, always quantitative and accurate falling, and inability to ensure constant or consistent ratio, etc., to achieve constant Effects of Sex and Consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

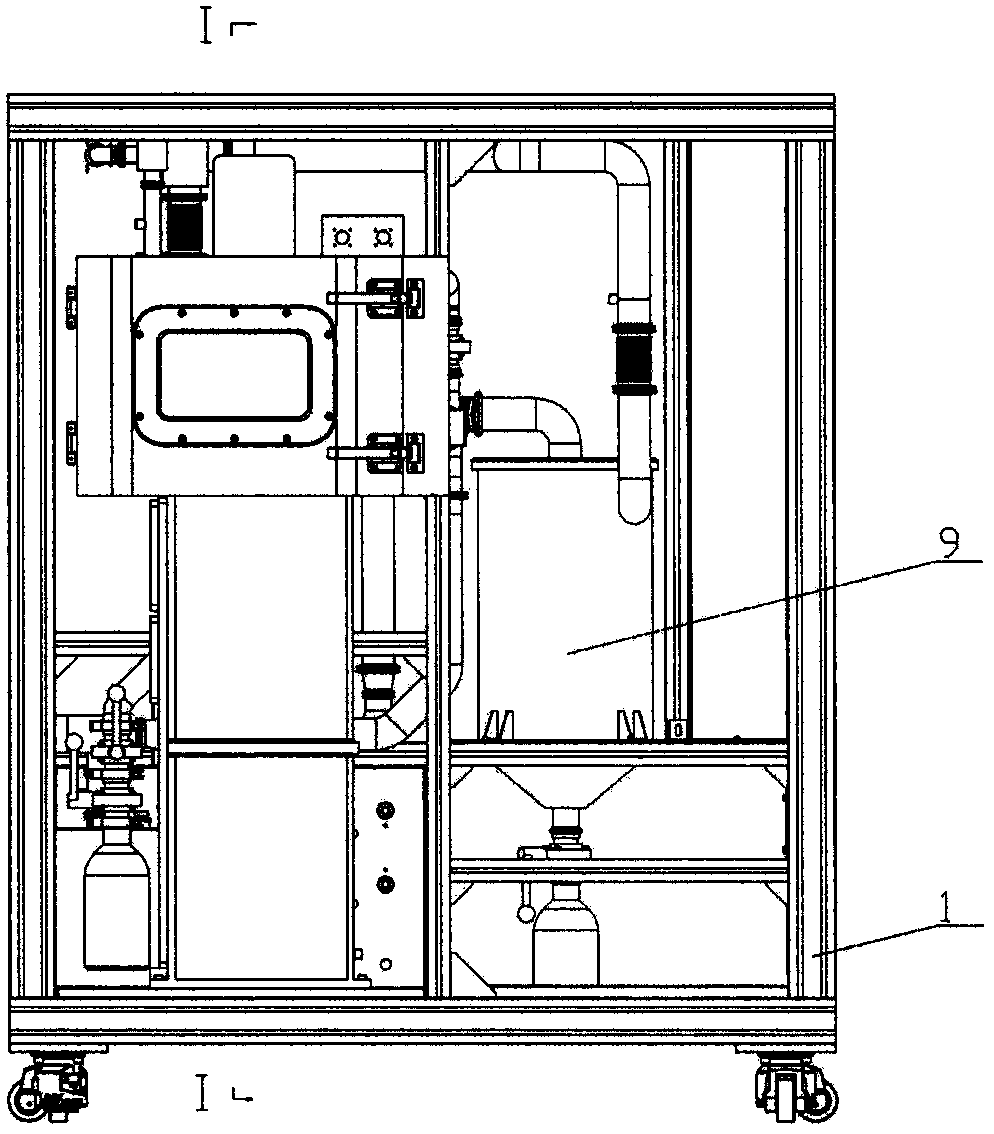

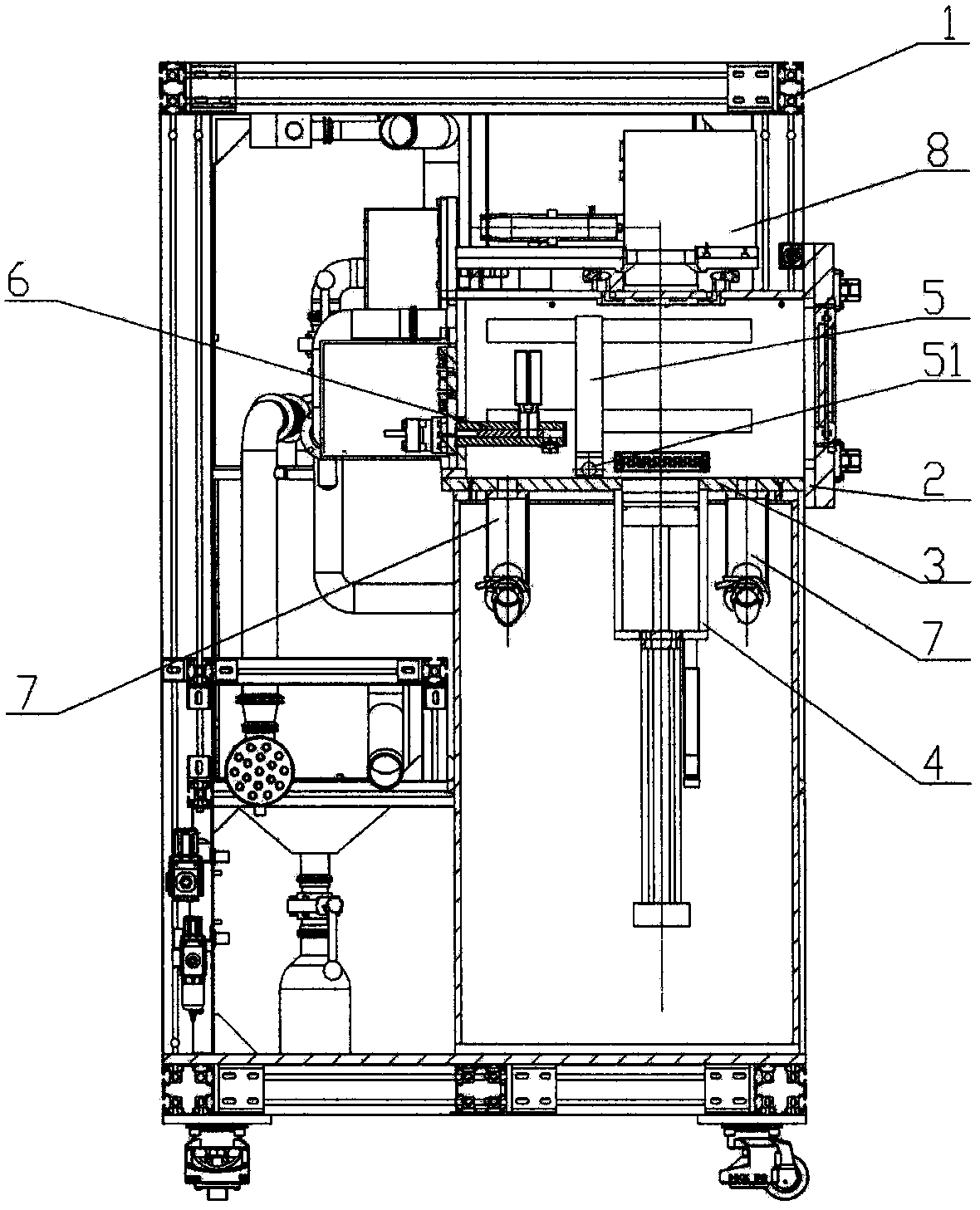

[0035] refer to figure 1 , figure 2As shown, the two figures show the overall layout of the 3D printer embodiment with a gradient powder supply system. Front and rear powder spreading is adopted. The powder supply system is above the workbench. There is a front blanking system in front of the forming cylinder, and a Back-blanking system, between the molding cylinder and the back-blanking system is the discharge port of the precise feeder of the gradient powder supply system. Just above the molding cylinder is an optical system such as a vibrating mirror, a laser, and a beam expander. In the sealed box, the sealed box is filled with inert protective gas during the working process, and the inert protective gas is recycled after passing through the dust removal and purification system. Before processing, first add enough powder to each stocker, seal the box and fill it with inert gas. Between the outlets of the feeder, the processing starts when the required process conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com