Cooling device and electronic device with cooling device

A technology for heat dissipation devices and electronic devices, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of reducing the overall size of the equipment, small volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

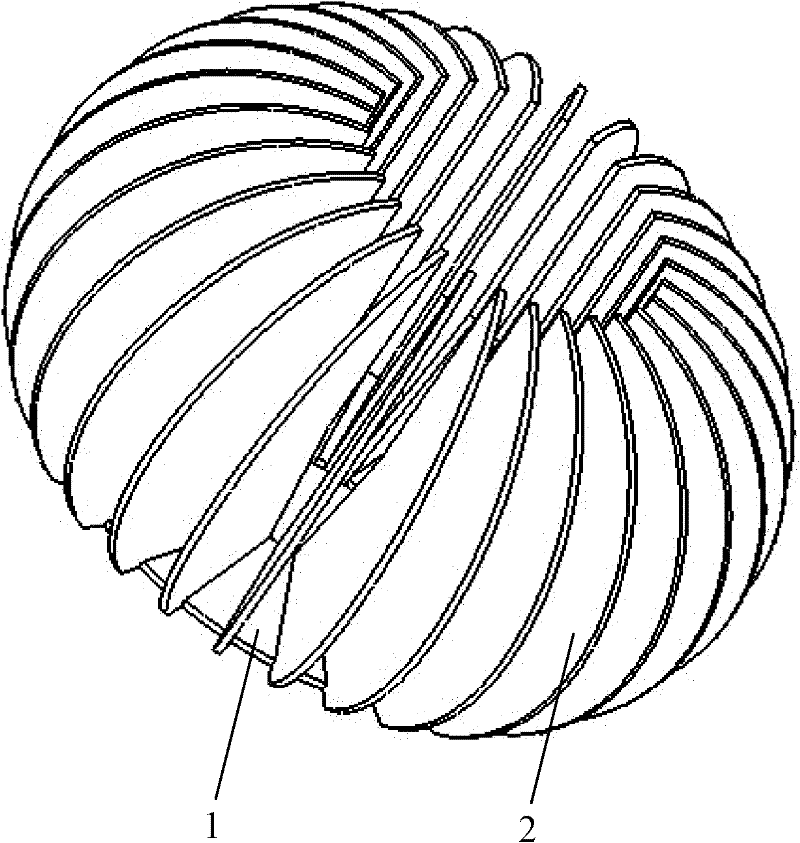

[0021] Figures 1 to 3 Three different embodiments of heat sinks according to the prior art are shown. exist figure 1 In the shown first embodiment, a plurality of heat sinks 2 are arranged on a rectangular heat conduction base 1 , and these heat sinks 2 stand vertically on the heat conduction base 1 in parallel with each other at a certain distance. The heat sink 2 can be integrally formed with the heat conduction base 1 , and of course they can also be formed separately. from figure 1 It can be seen from the figure that these heat sinks 1 are all flat heat sinks.

[0022] exist figure 2 In the shown second embodiment, a plurality of heat sinks 2 are arranged on the circular heat conduction base 1, and these heat sinks 2 are vertically erected on the heat conduction base 1 in a circle around each other, thereby forming a structure similar to The shape of the lantern, from figure 2 It can be seen from the figure that the heat sinks 1 are all flat heat sinks, and these ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com