Method for efficiently synthesizing DBE through supported bimetallic catalyst

A bimetallic catalyst, catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of reducing catalyst activity, etc. Small diameter, tightly combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

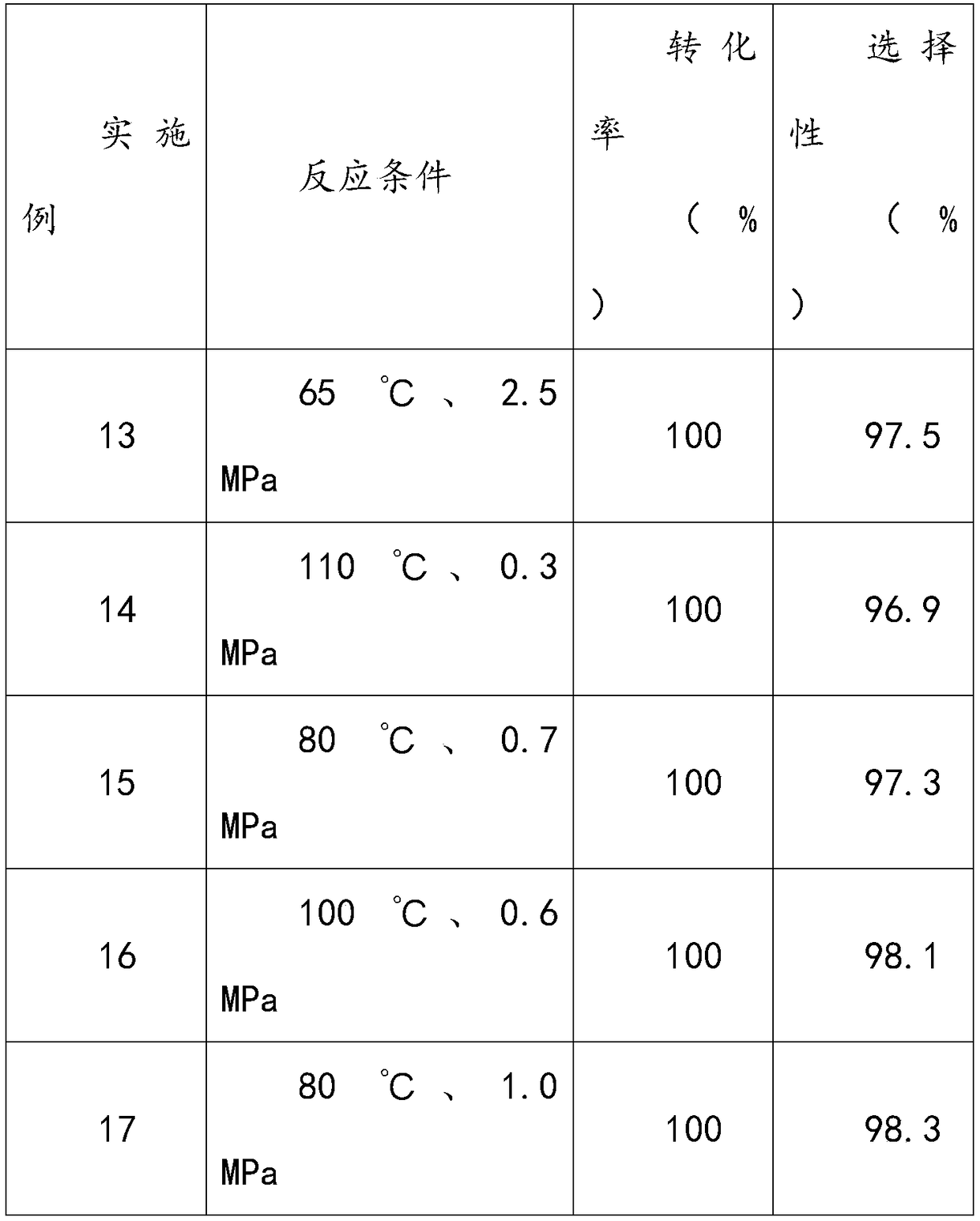

Examples

Embodiment 1

[0027] Take by weighing 10g gac, particle size is 800 orders, specific surface area is 1400m2 / g, pore volume is 0.6ml / g, configuration 6ml contains H2PdCl4 and ZnCl2 mixed solution (the quality that contains Pd in the mixed solution is 0.2g, the quality that contains Zn was 0.3g); the mixed solution was added dropwise to activated carbon, and stirred evenly. The impregnated catalyst was vacuum dried at 25°C for 10 h. The dried catalyst was reduced under H2 atmosphere at 60° C. for 6 h to obtain palladium-zinc catalyst supported on activated carbon.

Embodiment 2

[0029] Take by weighing 10g gac, particle size is 500 orders, specific surface area is 1200m2 / g, pore volume is 0.5ml / g, configuration 5ml contains H2PtCl6 and ZnCl2 mixed solution (the quality that contains Pt in the mixed solution is 0.2g, the quality that contains Zn was 0.4g); the mixed solution was added dropwise to activated carbon, and stirred evenly. The impregnated catalyst was vacuum dried at 20°C for 20 h. The dried catalyst was reduced under H2 atmosphere at 100° C. for 3 h to obtain a platinum-zinc catalyst supported on activated carbon.

Embodiment 3

[0031] Take by weighing 10g gac, particle size is 150 orders, specific surface area is 800m2 / g, pore volume is 0.8ml / g, configuration 8ml contains Pt(NO3) 2 and Zn(NO3) 2 mixed solution (the quality of Pt in the mixed solution is 0.4g, and the mass containing Zn is 0.2g); add the mixed solution dropwise to the activated carbon, and stir evenly. The impregnated catalyst was vacuum-dried at 30 °C for 4 h. The dried catalyst was reduced at 50° C. for 10 h under H2 atmosphere to obtain a platinum-zinc catalyst supported on activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com