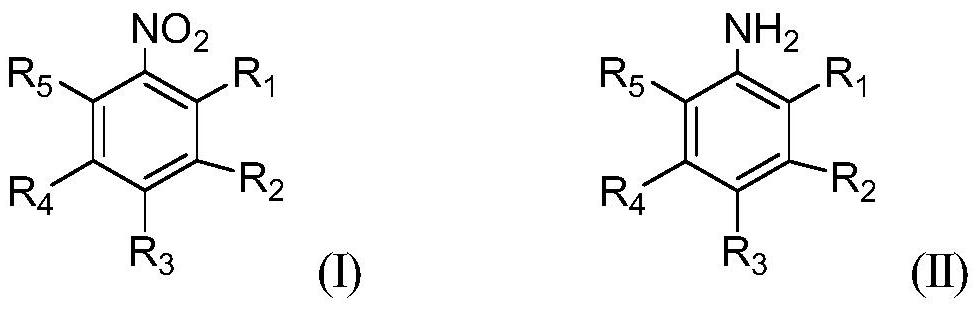

A stable and efficient catalytic hydrogenation method for the preparation of aromatic amines

A technology for catalytic hydrogenation and aromatic amines, which is applied in the preparation of amino compounds, cyanide reaction preparation, chemical instruments and methods, etc., can solve the problems such as the decline of hydrogenation catalysts, and achieves reduced content, small metal particle size, and high catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

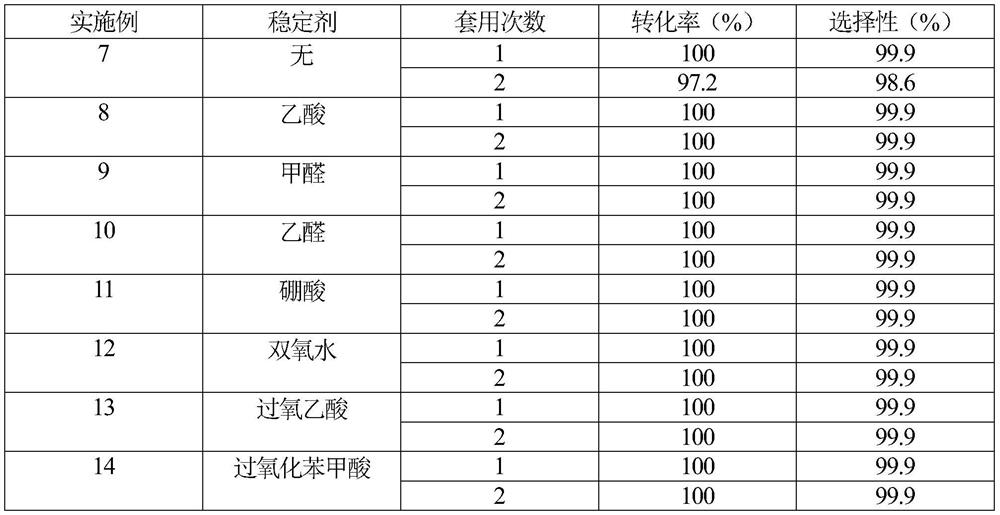

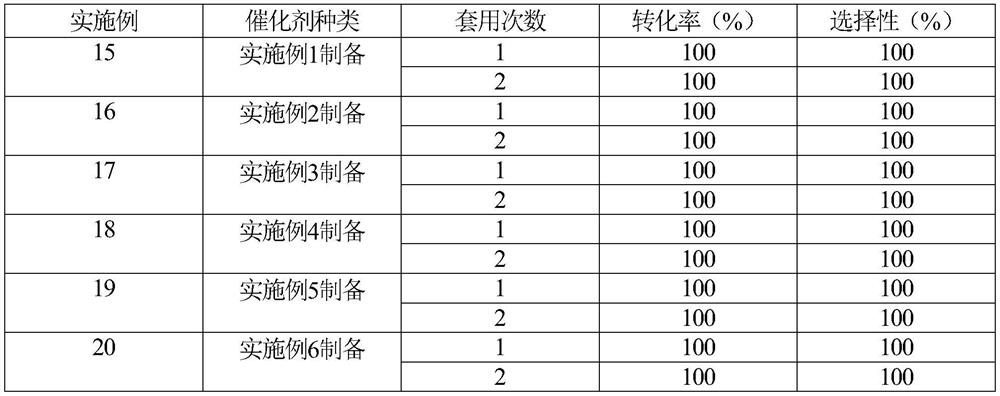

Examples

Embodiment 1

[0039] Weigh 10g of activated carbon with a particle size of 1000 mesh and a specific surface area of 1800m 2 / g, the pore volume is 0.6mL / g, first configure 6mL containing H 2 PdCl 4 , CuCl 2 and the mixed solution of furfural (the quality that contains Pd in the mixed solution is 0.01g, the quality that contains Cu is 0.01g, and the quality that contains furfural is 0.01g); The mixed solution is added dropwise in the gac, and stirs; Vacuum-dry the impregnated catalyst at 25°C for 10 h; configure 6 mL of the same mixed solution as above, impregnate with equal volume, and dry under the same conditions as above, so that a total of 5 times with equal volume; catalyst in H 2 Reduction was carried out at 60° C. for 6 hours under atmosphere to obtain a 3% Pd-3% Cu / C catalyst.

Embodiment 2

[0041] Weigh 10g of activated carbon with a particle size of 100 mesh and a specific surface area of 1000m 2 / g, the pore volume is 0.3mL / g, first configure 3mL containing H 2 PtCl 6 , CuCl2 and the mixed solution of furfural (the quality containing Pt in the mixed solution is 0.02g, the quality containing Cu is 0.01g, and the quality containing furfural is 0.02g); at 25 ℃, the mixed solution is added dropwise in the activated carbon, and Stir evenly; vacuum-dry the impregnated catalyst at 20°C for 20 hours; configure 3mL of the same mixed solution above, impregnate with equal volume, and dry under the same conditions as above, so that a total of equal volume impregnate 10 times; catalyst in H 2 Reduction was carried out at 80° C. for 3 h under atmosphere to obtain a 6% Pt-3% Cu / C catalyst.

Embodiment 3

[0043] Weigh 10g of activated carbon with a particle size of 400 mesh and a specific surface area of 1600m 2 / g, the pore volume is 0.8mL / g, first configure 8mL containing Pt(NO 3 ) 2 , Cu(NO 3 ) 2 and the mixed solution of furfural (the quality containing Pt in the mixed solution is 0.01g, the quality containing Cu is 0.01g, and the quality containing furfural is 0.02g); at 20 ℃, the mixed solution is added dropwise in the activated carbon, and Stir evenly; vacuum-dry the impregnated catalyst at 20°C for 7 hours; configure 8ml of the same mixed solution as above, impregnate with equal volume, and dry under the same conditions as above, so that a total of equal volume impregnate 5 times; catalyst in H 2 Reduction was carried out at 70° C. for 5 h under atmosphere to obtain a 4% Pt-4% Cu / C catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com