Laminated microchannel reactor and mold pressing device integrated system and method

A microchannel reactor and stacked technology, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, inorganic chemistry, etc., can solve problems such as energy saving and high emissions without consideration, and achieve broad prospects and market value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

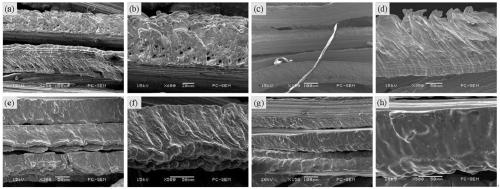

[0045] The sintering atmosphere is set to complete reduction atmosphere, low temperature reduction atmosphere, high temperature reduction atmosphere, neutral atmosphere and oxidation atmosphere, and the sintering time is set to 30min and 60min.

[0046] The so-called oxidizing atmosphere means that there is no gas protection during the sintering process; the neutral atmosphere means that the sintering is always under the protection of nitrogen; the high-temperature reducing atmosphere means that nitrogen is used to protect the fiber carrier first, and then hydrogen is introduced when the temperature rises to 600 °C. After the heat preservation is completed and the temperature is lowered to 600°C, the hydrogen valve is closed and then nitrogen gas is introduced; the low-temperature reduction atmosphere is similar to the high-temperature reduction atmosphere process, except that the gas conversion temperature is changed from 600°C to 400°C; Introduce hydrogen, and always keep sin...

Embodiment 2

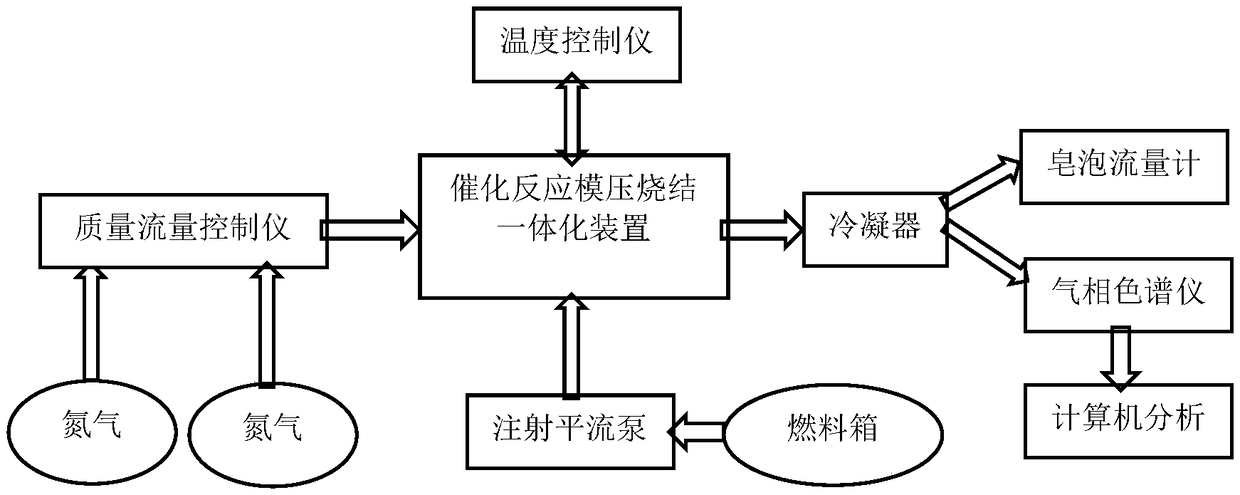

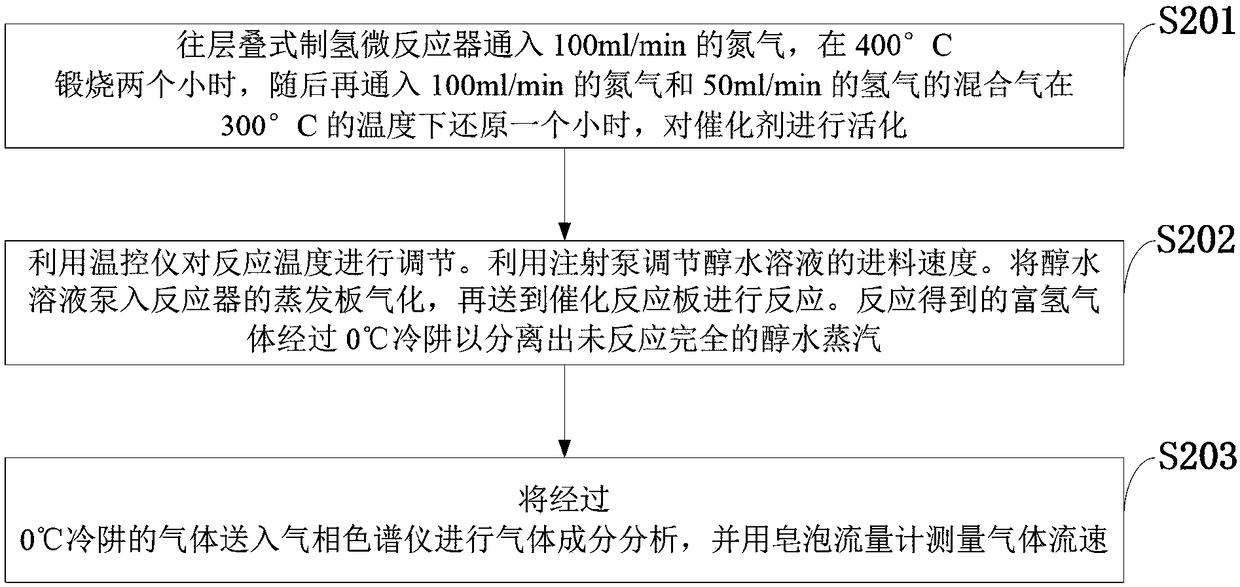

[0057] like Figure 4 As shown, the methanol steam reforming microreactor is composed of an evaporation chamber and a reaction chamber, and the cut fiber sintered support (FSF) and smooth fiber sintered support (WSF) loaded with Cu / Zn / Al / Zr quaternary system catalyst into the reaction chamber. The reaction temperature was adjusted by a temperature controller. The syringe pump is injected with a certain proportion of methanol and water mixed liquid, and pumped into the evaporation chamber for vaporization, and then sent to the reaction chamber for reforming reaction. The hydrogen-rich gas obtained from the reaction is passed through a 0°C cold trap to separate unreacted methanol and water, and then the gas is sent to a gas chromatograph for gas composition analysis and a soap bubble flowmeter to measure the gas flow rate. The test principle is as follows Figure 7 shown.

[0058] Methanol conversion and hydrogen selectivity are important indicators for evaluating the perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com