Stirring structure and stirring type slurry energy storage device

An energy storage device, stirring technology, applied in transportation and packaging, chemical/physical/physical chemical processes of energy application, mixers, etc., can solve the problems of blocked flow channels and diaphragms, reduced energy density, uneven stirring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

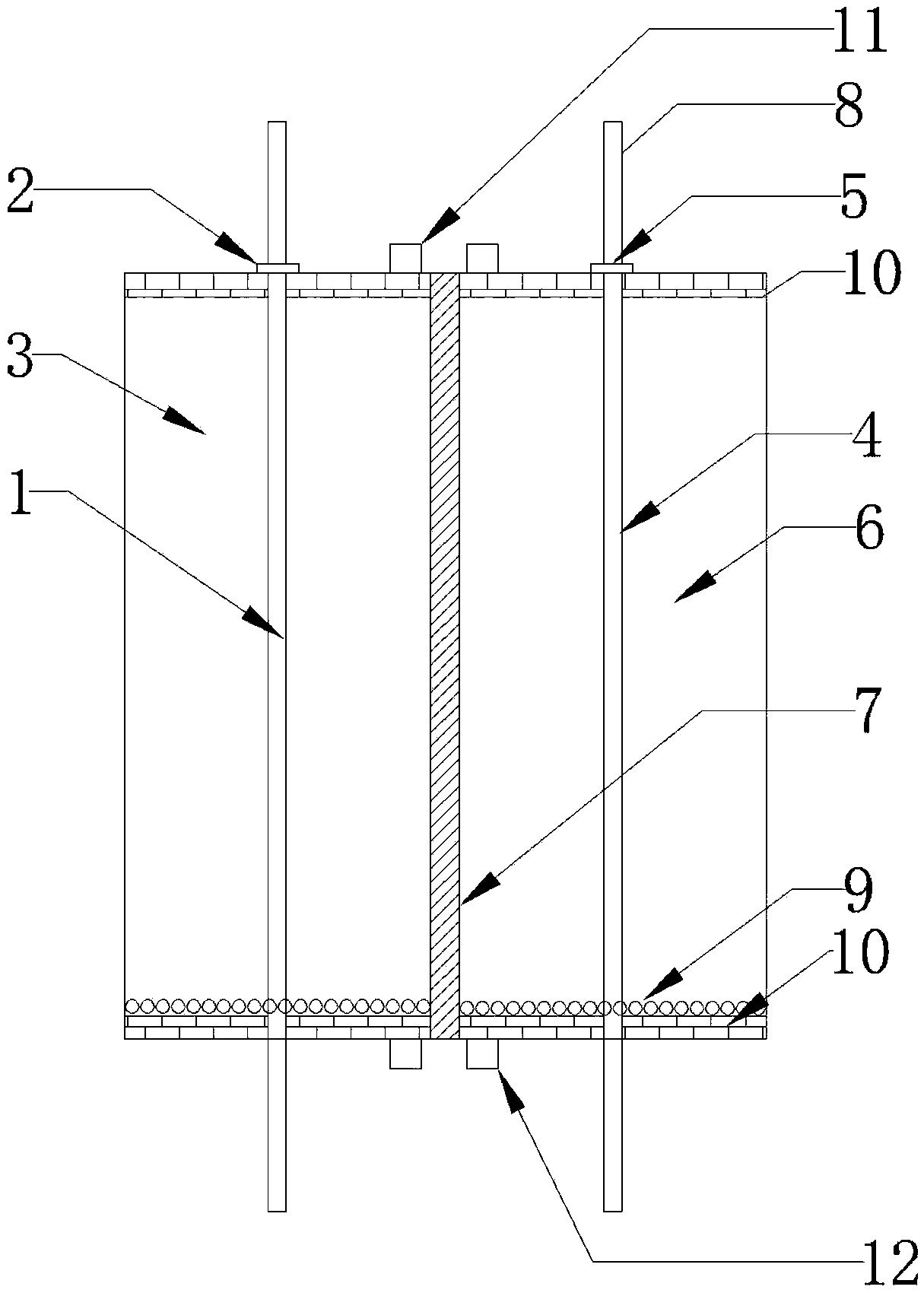

[0028] This embodiment provides a stirring structure, which includes a chamber, electromagnets 10 arranged at both ends of the chamber, and magnets 9 arranged in the chamber; the electromagnets 10 at both ends are turned on and off Switching, the magnet 9 moves under the action of the magnetic field of the electromagnet 10 .

[0029] The magnet 9 is set as a magnet 9 made of iron, cobalt, nickel or ferrite and other magnetic materials, and the magnet has one or more different diameters, and its diameter ranges from 10 μm to 1 mm.

[0030] In this embodiment, the magnetic field is switched by turning on and off the electromagnets 10 at both ends, so that the magnets 9 run in different directions, so as to achieve the purpose of stirring. Its structure is simple, easy to operate and has good stirring effect.

Embodiment 2

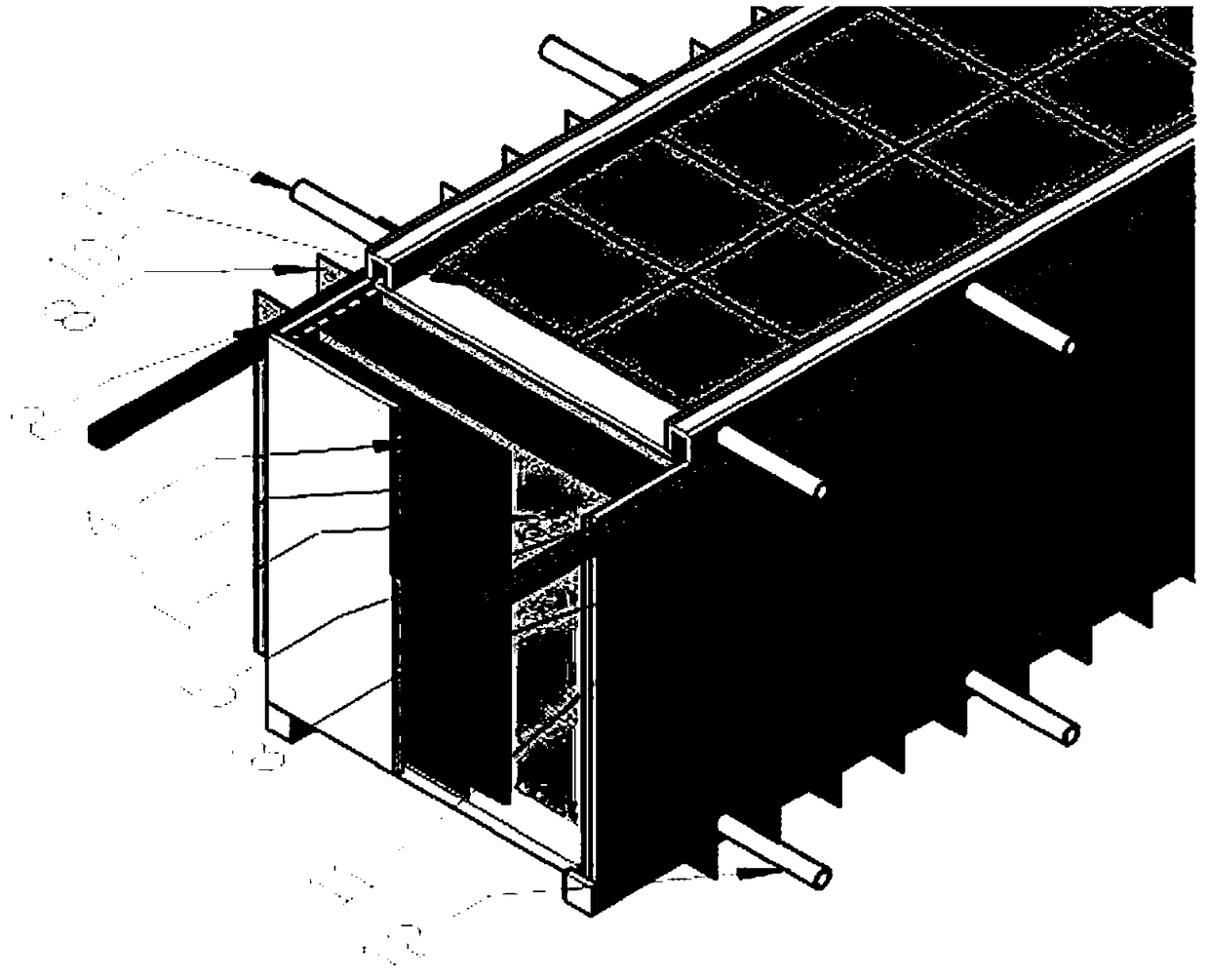

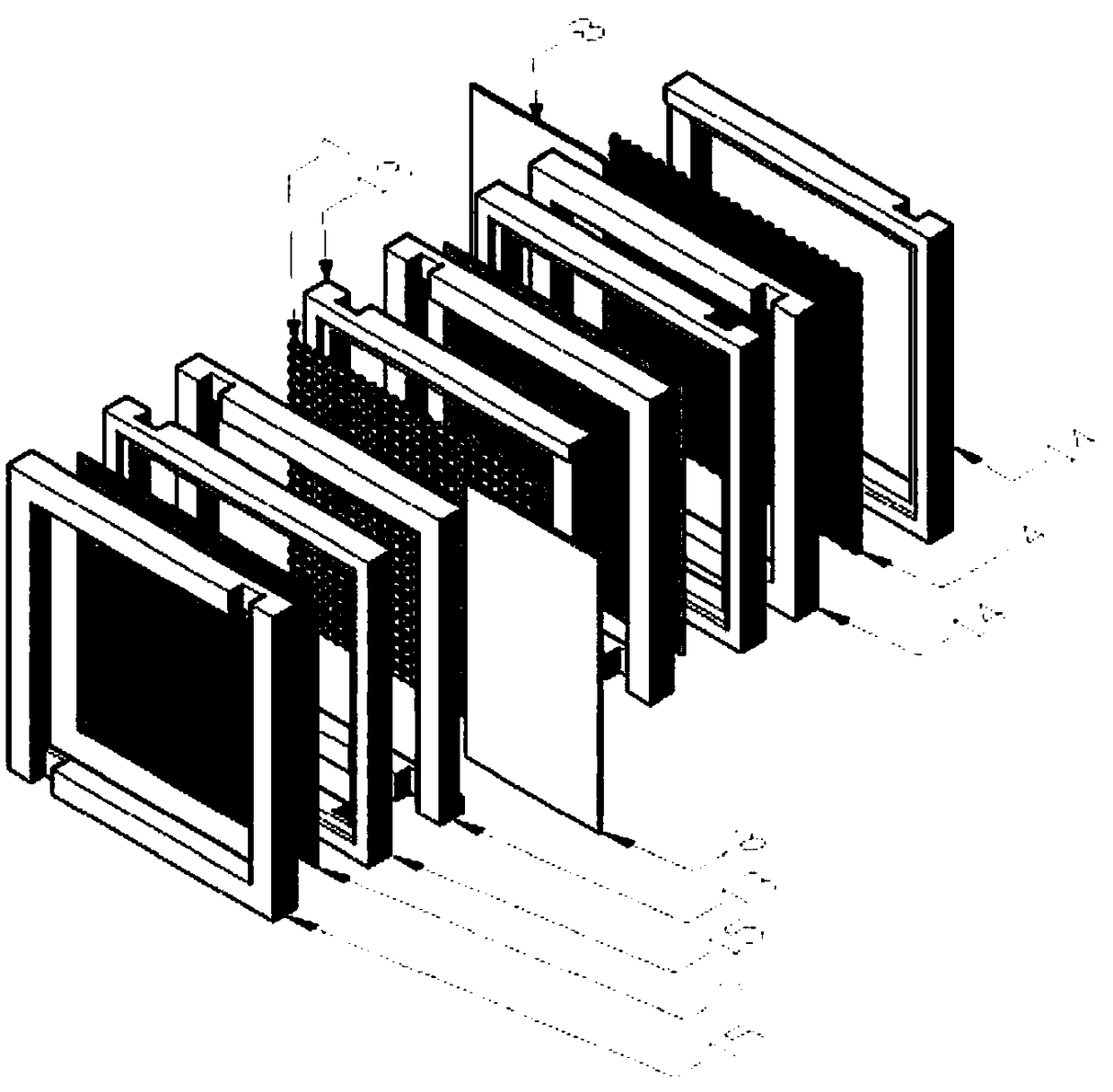

[0032] Such as figure 1 , 2 As shown in and 3, the present embodiment provides a stirring type slurry energy storage device, which includes an electrochemical reactor, and also includes a stirring structure located in the positive electrode chamber 3 and the negative electrode chamber 6 of the electrochemical reactor , the stirring structure includes electromagnets 10 arranged at both ends of the chamber and magnets 9 arranged in the chamber; the electromagnets 10 at both ends are switched on and off according to the driving working system, and the The magnet 9 moves under the action of the magnetic field of the electromagnet 10 to stir the slurry in the chamber.

[0033] In this embodiment, the magnetic field is switched by turning on and off the electromagnets 10 at both ends, so that the magnets 9 run in different directions, so as to achieve the purpose of stirring. The structure is simple, easy to operate and has a good stirring effect; at the same time , intermittent s...

Embodiment 3

[0060] On the basis of Embodiment 2, this embodiment provides a specific stirring type slurry energy storage device, as follows:

[0061] The designed installed capacity is 750kwh, and the designed maximum power is 1mw. The whole device is about 0.8m high and covers an area of 2m 2 Left and right, the volume energy density of the device is about 469wh / L, which is basically the same as the current volume energy density of lithium-ion batteries. The device stirs the slurry intermittently during the high-power charging and discharging process, and stirs the slurry after a single charging and discharging cycle.

[0062] The internal length and width of the electrochemical reactor of the device are 83cm×200cm×30cm, specifically as image 3 As shown, grooves are engraved on the inside of the upper and lower shells. Among them, the positive current collector 1 is made of 100-mesh metal aluminum mesh, and the negative electrode current collector 4 is made of 100-mesh metal copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com