Camera processing method

A processing method and camera technology, applied in manufacturing tools, image communication, television, etc., can solve the problems of low processing efficiency of cameras, and achieve the effects of short processing time, time saving and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

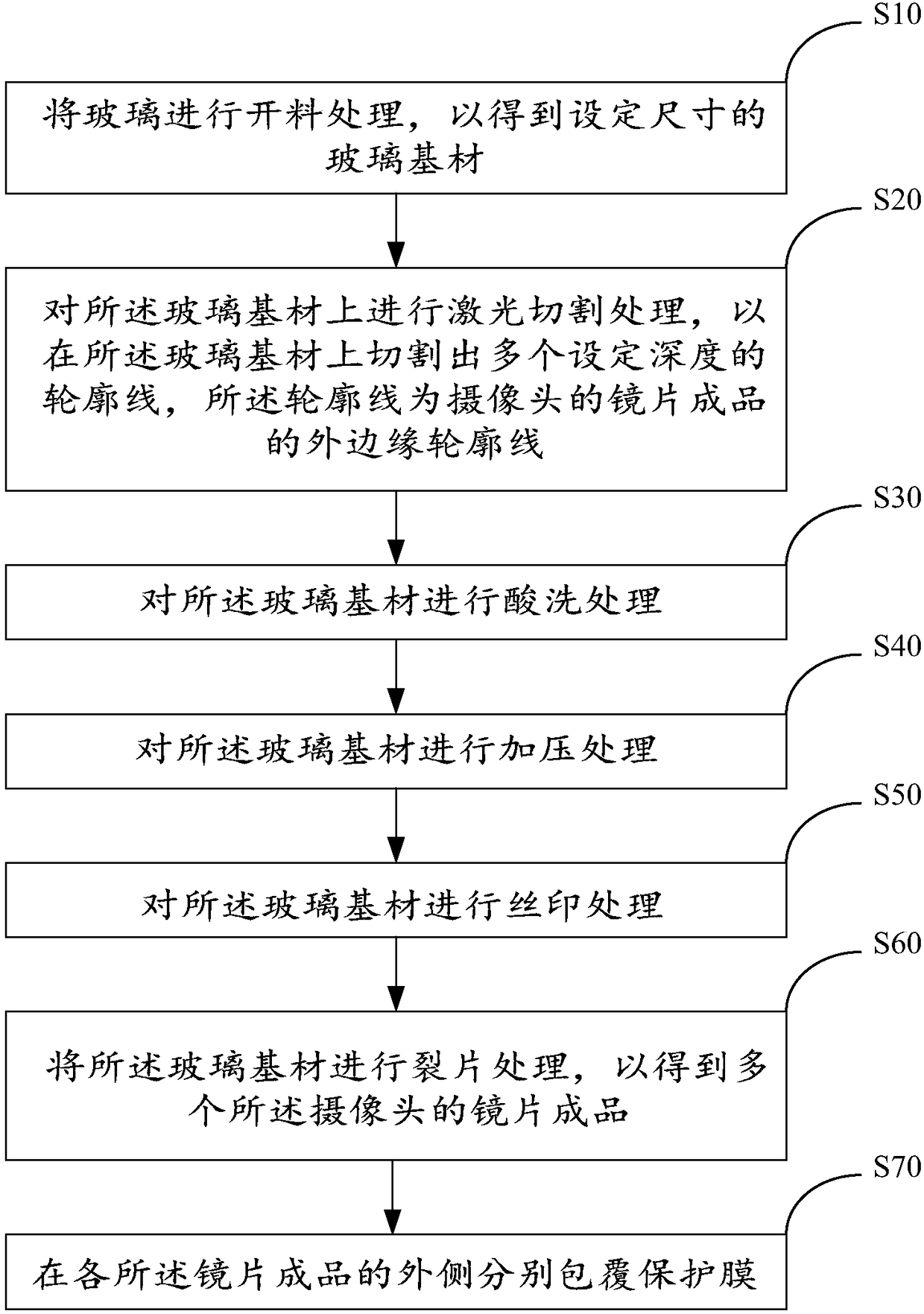

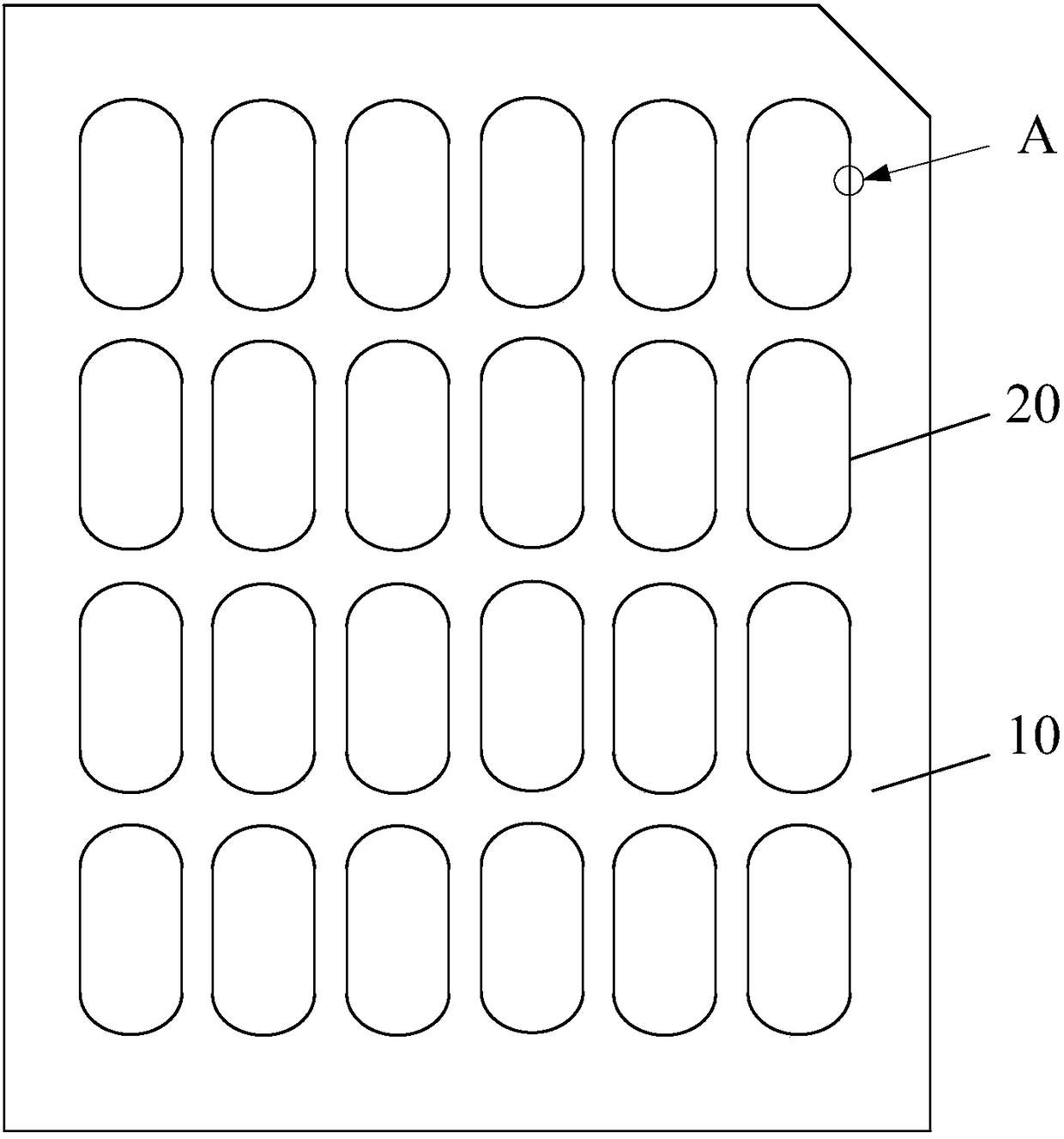

[0051] figure 1 It is a schematic diagram of the technological process of the camera processing method in Embodiment 1 of the present invention, Figure 2-6 It is a schematic diagram of semi-finished or finished products in the process of camera processing.

[0052] Such as Figure 1-6 As shown, the camera processing method provided by the embodiment of the present invention includes:

[0053] S10 , performing a cutting process on the glass to obtain a glass substrate 10 with a predetermined size.

[0054] During specific operations, the cutting process includes flat grinding and polishing the glass substrate 10 so that the thickness and surface roughness of the glass substrate 10 reach the set thickness and surface roughness of the camera. The size of the glass substrate 10 obtained by the cutting process is much larger than the size of a finished lens 40, from figure 2 As can be seen, figure 2 The size of the glass substrate 10 is greater than the size of the twenty-f...

Embodiment 2

[0077] Embodiment 2 of the present invention proposes another camera processing method, including:

[0078] Cutting the glass to obtain a glass substrate with a set size;

[0079] Carry out laser cutting on the glass substrate to cut a plurality of contour lines with a set depth on the glass substrate, and the contour lines are the contour lines of the outer edge of the finished lens of the camera;

[0080] Pickling the glass substrate;

[0081] Splitting the glass substrate to obtain multiple semi-finished lenses with the same size as the finished lens of the camera;

[0082] Pressurize each lens semi-finished product;

[0083] Screen printing is performed on each semi-finished lens to obtain a finished lens.

[0084] In the camera processing method provided in Embodiment 2 of the present invention, laser cutting is performed on the large glass substrate obtained after the cutting process, so as to cut out the contour lines of a plurality of lens products on the glass subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com