An air-cooled module for heat transfer temperature uniformization of a fuel cell

A fuel cell and air-cooled technology, which is applied in the fields of fuel cell heat exchange, fuel cell, fuel cell additives, etc. The thermal performance is stable and reliable, the effect of solving the heat dissipation problem and improving the output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

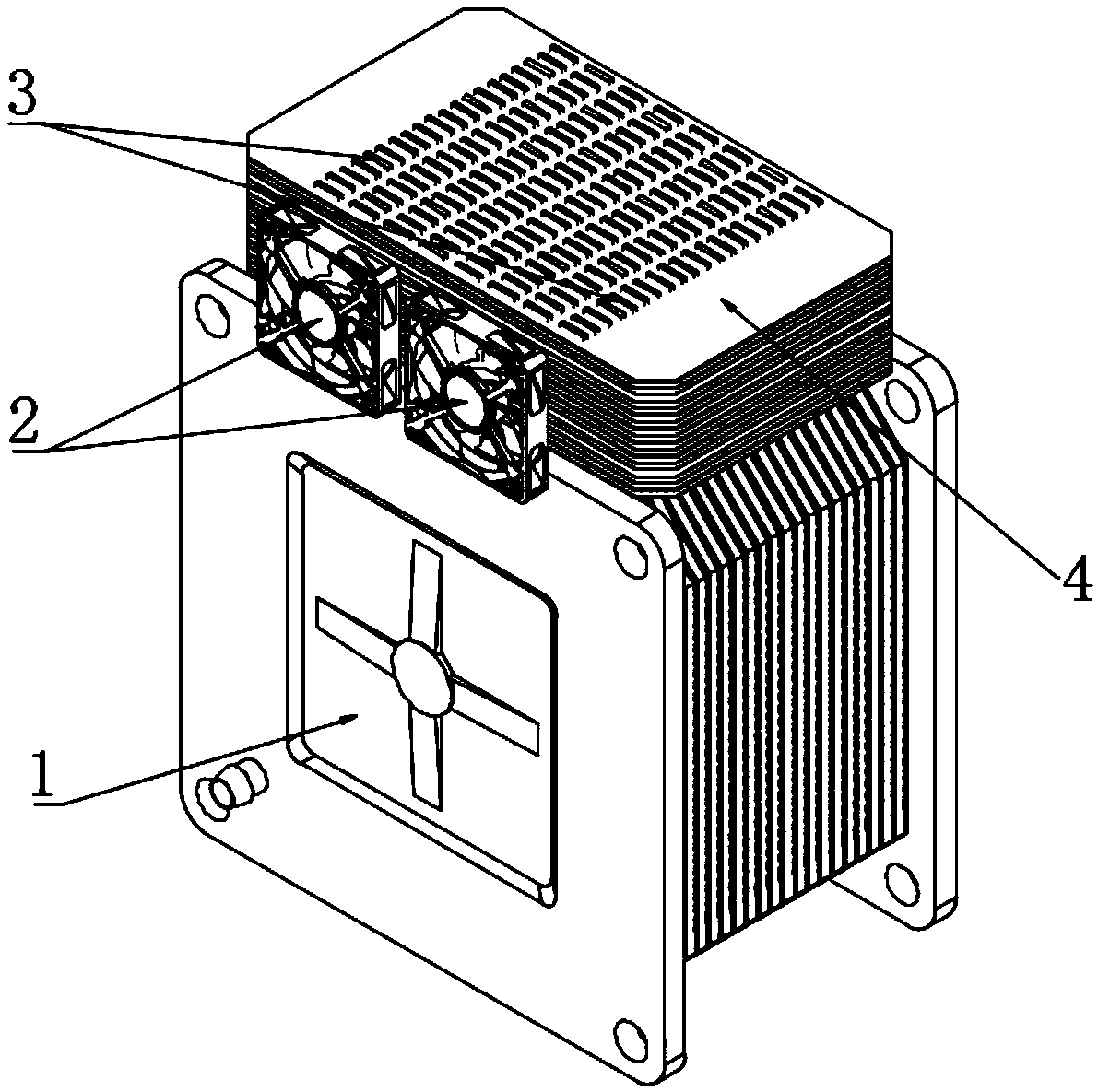

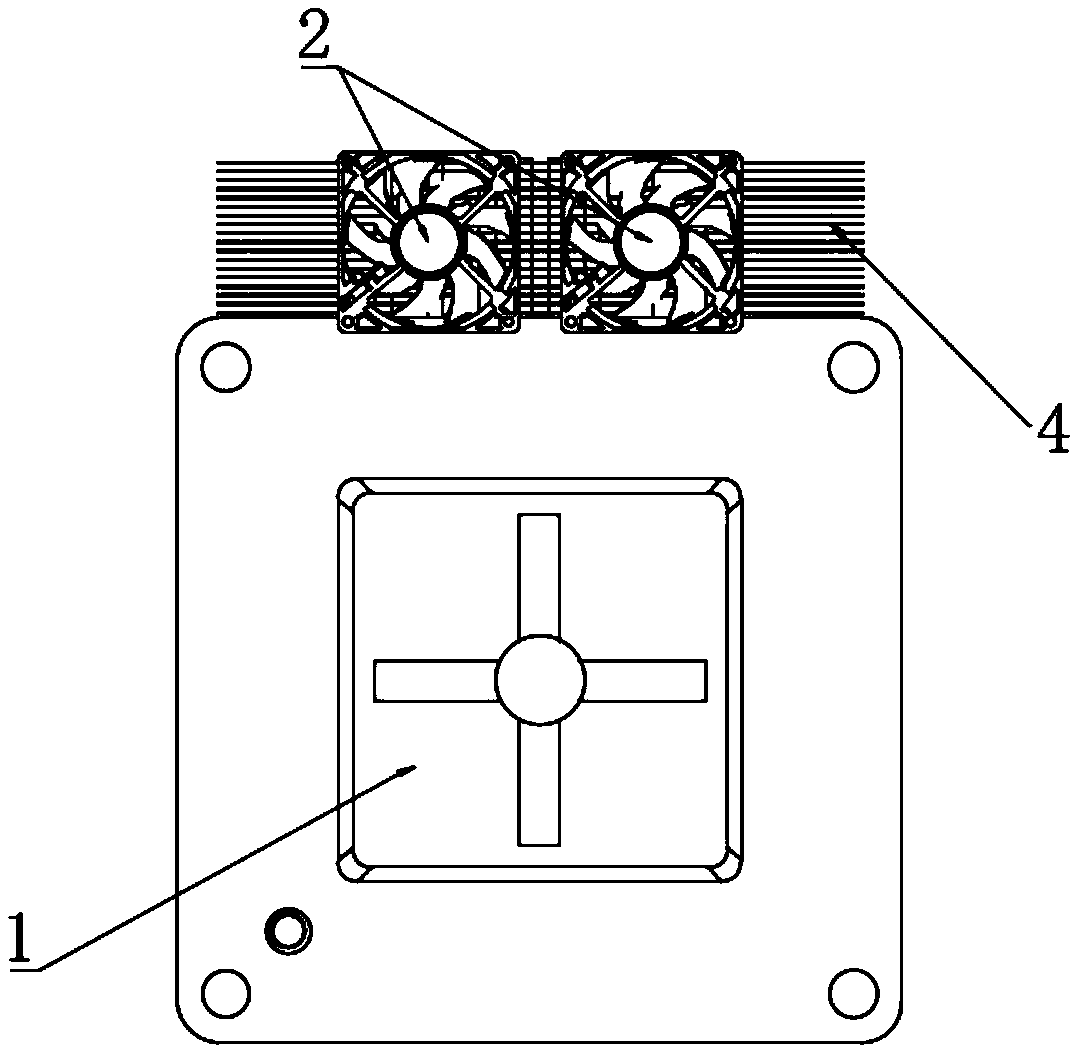

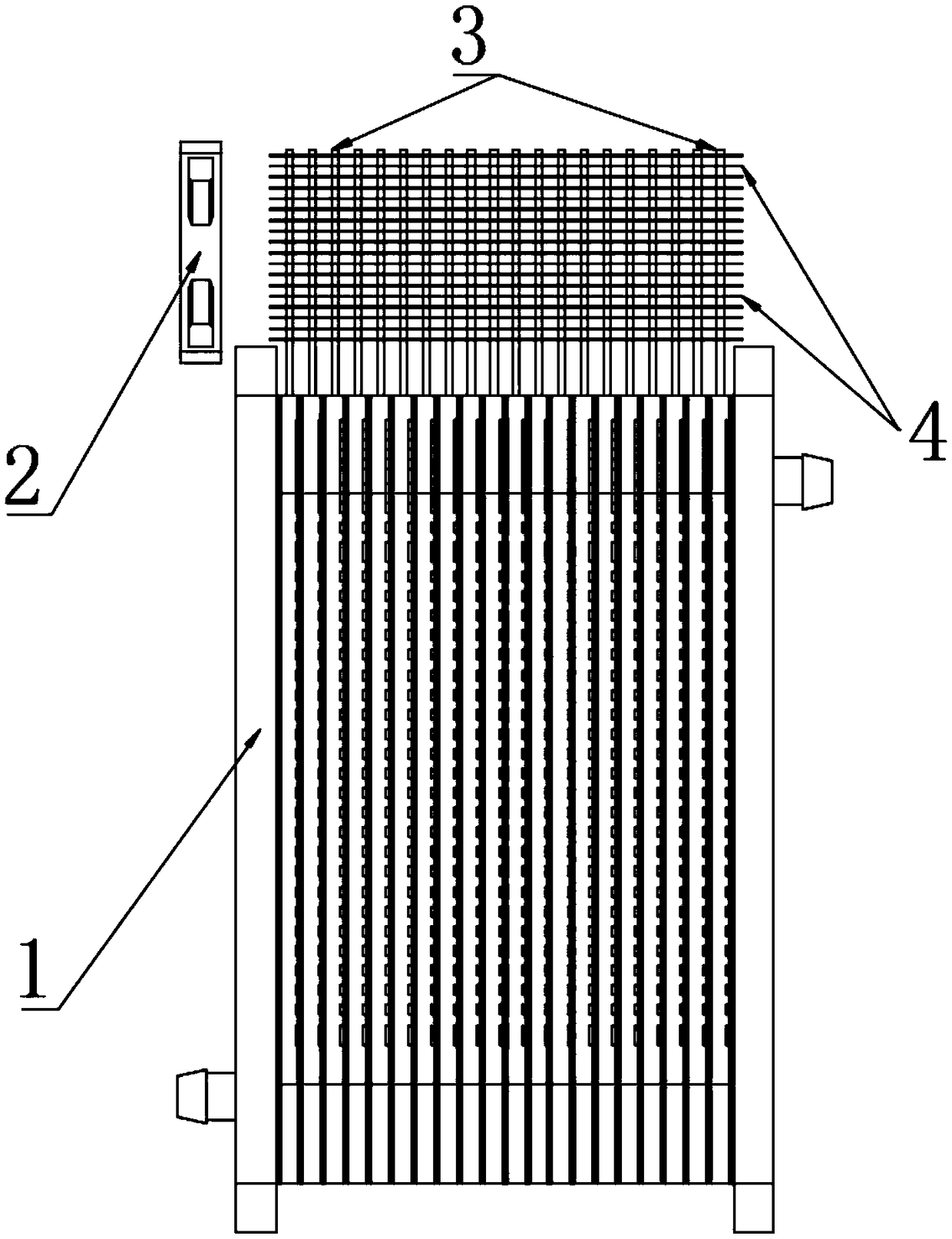

[0046] Such as Figure 1-Figure 8 As shown, an air-cooled module for heat transfer and uniform temperature of fuel cells is mainly composed of fuel cell assembly 1, fan system 2 and fins 4; fuel cell assembly 1 includes end cover 1-1, membrane electrode 1- 2 and ultra-thin vapor chamber 3; membrane electrodes 1-2 are preferably MEA membrane electrodes; multiple membrane electrodes 1-2 and multiple ultra-thin vapor chambers 3 are arranged alternately, and the two sides of each membrane electrode 1-2 are respectively set There is an ultra-thin vapor chamber 3, and the outermost ultra-thin vapor chamber 3 is connected to the end cover 1-1; the ultra-thin vapor chamber 3 includes a shell, a cavity, a liquid-absorbing core 3-3 and working fluid; The ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com