A conductive rod for a vacuum interrupter and a processing method thereof

A technology of vacuum interrupter and conductive rod, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of high cost, inability to realize one-time sealing and discharge, long process, etc., and achieve small contact resistance and good shape and position tolerance , Improve the effect of insulation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

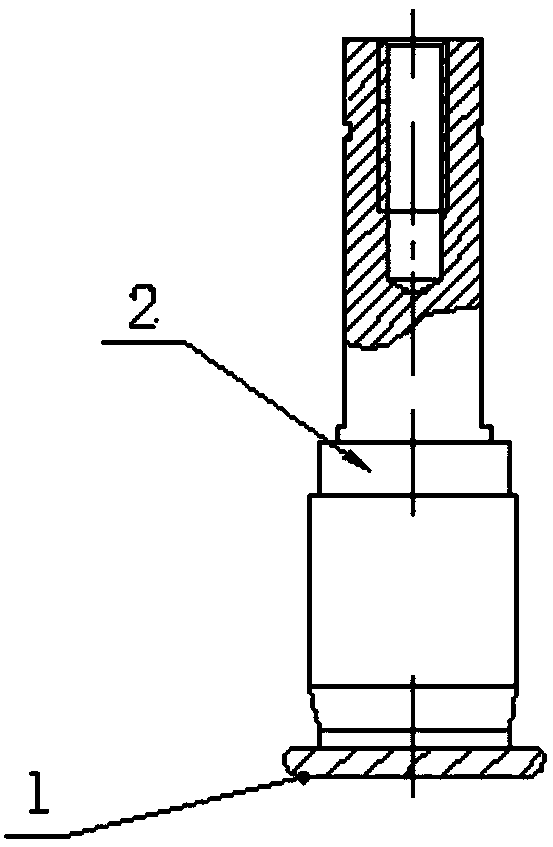

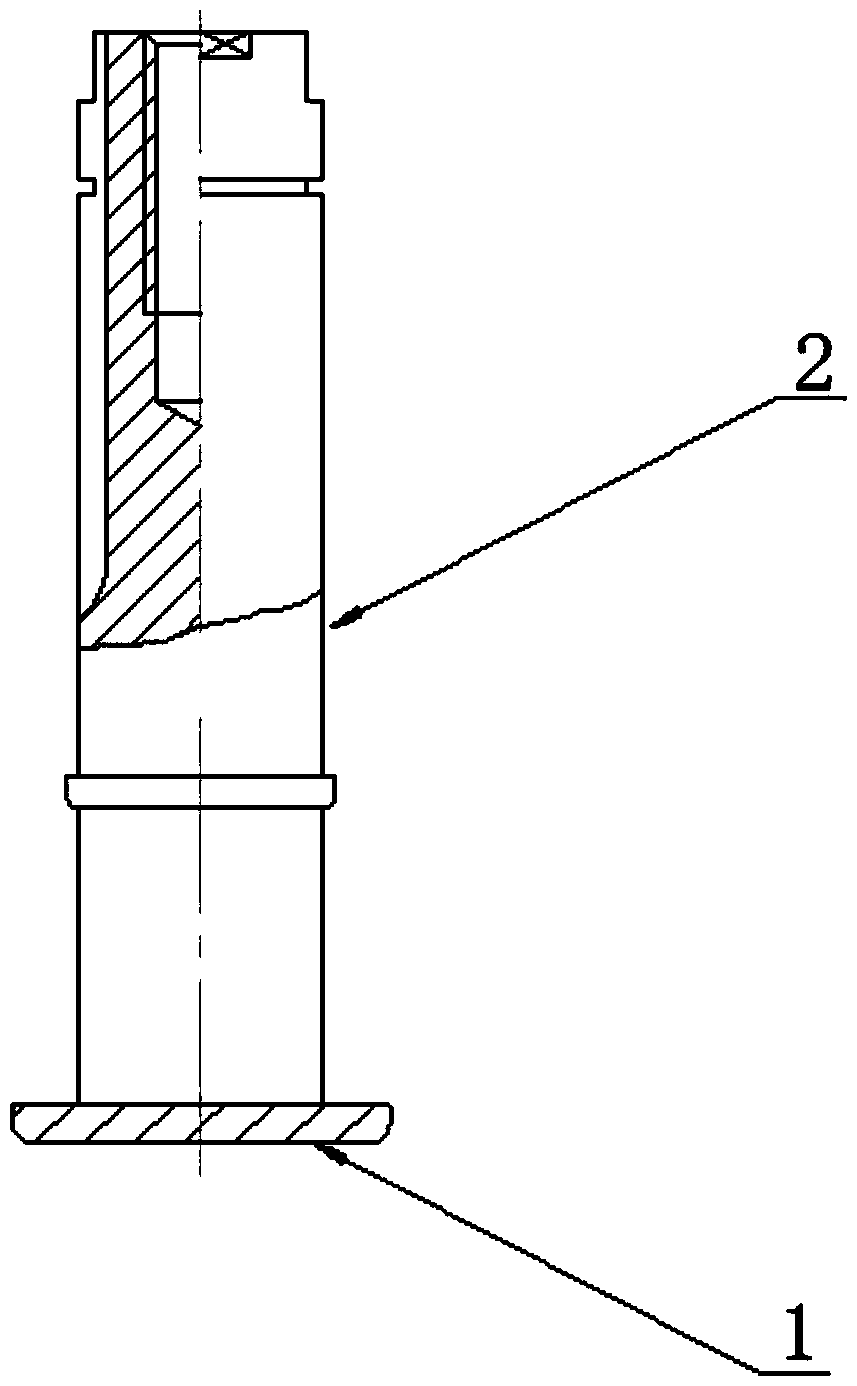

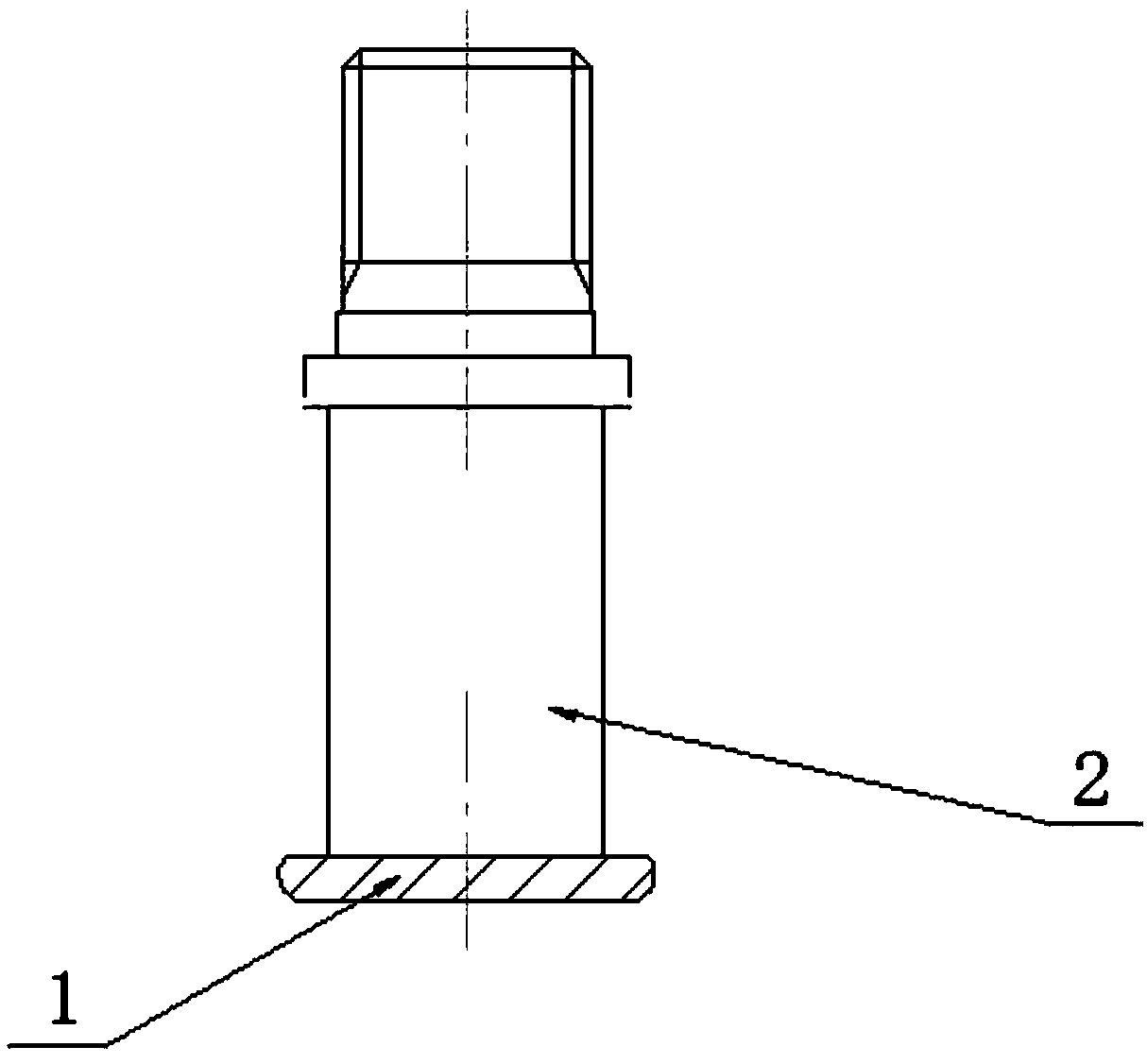

[0042] Step 1. Select copper-clad tungsten-copper contact 1 of appropriate specifications (tungsten mass content 70%, copper mass content 30%), first flatten the copper-clad end surface, and then flatten the end surface of the oxygen-free copper rod (TU0 or TU1) of the same specification Cheping then uses high-speed friction welding to weld the two metals together. A conductive rod blank for a vacuum interrupter in which the tungsten copper contact 1 (tungsten content 70%, copper content 30%) and the oxygen-free copper guide rod (TU0 or TU1) are integrated is obtained.

[0043] Step 2, the conductive rod blank for the vacuum interrupter obtained in step 1 is subjected to conventional mechanical processing, and then undergoes conventional production processes of conductive rods such as drilling, tapping, and slot milling, and finally deburrs and cleans, that is, Obtain dynamic / static conduction rods for vacuum interrupters.

Embodiment 2

[0045] Step 1. Select a copper-clad tungsten-copper contact with a suitable specification (tungsten mass content 80%, copper mass content 20%), first flatten the copper-clad end face, and then carve the end face of the same specification oxygen-free copper rod (TU0 or TU1) flat, and then use plasma welding to weld the two metals together. A conductive rod blank for a vacuum interrupter in which the tungsten-copper contact (80% tungsten content, 20% copper content) and the oxygen-free copper rod (TU0 or TU1) are integrated is obtained.

[0046]Step 2, the conductive rod blank for the vacuum interrupter obtained in step 1 is subjected to conventional mechanical processing, and then undergoes conventional production processes of conductive rods such as punching, tapping, and slot milling, and finally deburring and cleaning, that is, Obtain dynamic / static conduction rods for vacuum interrupters.

Embodiment 3

[0048] Step 1. Select a copper-clad tungsten-copper contact with a suitable specification (90% tungsten mass content, 10% copper mass content), first flatten the copper-clad end face, and then carve the end face of the same specification oxygen-free copper rod (TU0 or TU1) flat, and then use high-speed friction welding to weld the two metals together. A conductive rod blank for a vacuum interrupter in which the tungsten-copper contact and the oxygen-free copper rod are integrated is obtained.

[0049] Step 2, the conductive rod blank for the vacuum interrupter obtained in step 1 is subjected to conventional mechanical processing, and then undergoes conventional production processes of conductive rods such as punching, tapping, and slot milling, and finally deburring and cleaning, that is, Obtain dynamic / static conduction rods for vacuum interrupters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com