Method for obtaining uniaxial stress-strain relation of material by pressing spherical pressure head in by repeatedly loading and unloading

A technology of spherical indenter and strain relationship, applied in the direction of analyzing materials, testing material hardness, instruments, etc., can solve the problems that the measurement accuracy depends on the reliability of finite element simulation results, and the accuracy of non-power strengthened materials is difficult to guarantee, so as to overcome time-consuming Laborious and unreliable effects of fitting results

Inactive Publication Date: 2018-12-18

SHANDONG UNIV

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method also needs to use finite element simulation to press the spherical indenter into the undetermined parameters in the calibration equation (8), so the calculation accuracy largely depends on the reliability of the finite element simulation results

And the test materials are limited to power-strengthened materials, and it is difficult to guarantee the test accuracy of non-power-strengthened materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

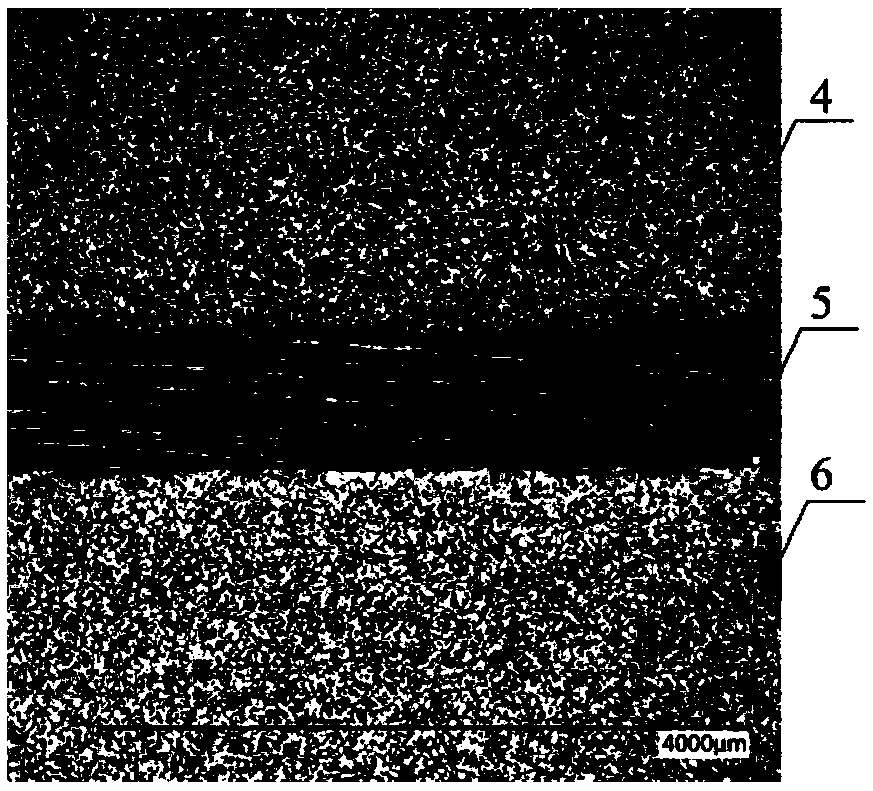

[0059] Embodiment: Apply the method of the present invention to obtain the uniaxial stress-strain relationship of 15CrMoR steel.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

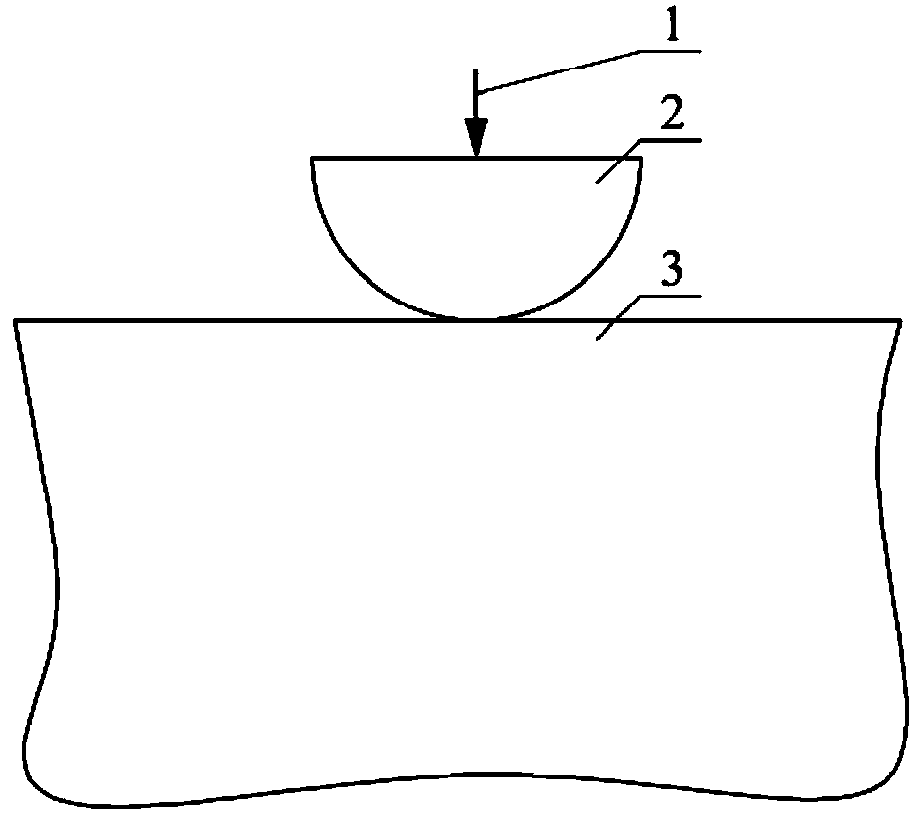

The invention relates to the field of testing of uniaxial stress-strain relation of in-service engineering structural materials, in particular to a method for obtaining the uniaxial stress-strain relation of a material by pressing a spherical pressure head in by repeatedly loading and unloading. The method comprises the steps that firstly, the hard material spherical pressure head is adopted to bepressed in the smooth surface of the tested material in an N-time quasi-static repeated loading and unloading mode to obtain a continuous pressing load P-pressing-in depth h curve, the plastic zone radius rp around a residual indentation pit is then measured after the press-in test is completed, and the method is used for processing data to draw a stress sigma-strain epsilon scatter plot similarto an uniaxial mechanical property test result. The method overcomes the local occasion limitation of the tested material range caused by the dependence of an existing spherical pressure head pressing-in test technology on a specific constitutive relation, the defects of time-consuming and labor-consuming and unreliable of fitting results caused by the fact that a large number of finite element simulation results or experimental result experience summary are required in the existing spherical pressure head pressing-in test technology are overcome, and the popularization and application of thespherical pressure head pressing-in test technology are facilitated.

Description

1. Technical field [0001] The invention relates to the field of testing the uniaxial stress-strain relationship of in-service engineering structure materials, in particular to a method for obtaining the uniaxial stress-strain relationship of materials by repeatedly loading and unloading spherical indenters. 2. Background technology [0002] The uniaxial stress-strain relationship is the basis for determining the yield strength, tensile strength and fracture toughness of materials, and plays a vital role in the structural integrity assessment of in-service engineering components. Traditional uniaxial tensile or uniaxial compression methods for obtaining uniaxial mechanical properties require destructive sampling according to standard sizes, so they cannot be fully applied to in-service engineering structures. In addition, the size requirements of traditional uniaxial mechanical tests also limit their application in the evaluation of local material mechanical properties such a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/42

CPCG01N3/42G01N2203/0005G01N2203/0019G01N2203/0075G01N2203/008

Inventor 王威强张泰瑞王尚

Owner SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com