A simulation test method for tier III performance of marine low-speed diesel engine

A simulation test, diesel engine technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of large space occupation, long installation and debugging cycle, affecting the normal debugging of diesel engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The simulation test method for the Tier III performance of a marine low-speed diesel engine described in the present invention is suitable for the bench test of a sub-type machine shop of a marine low-speed diesel engine set installed with an HPSCR device.

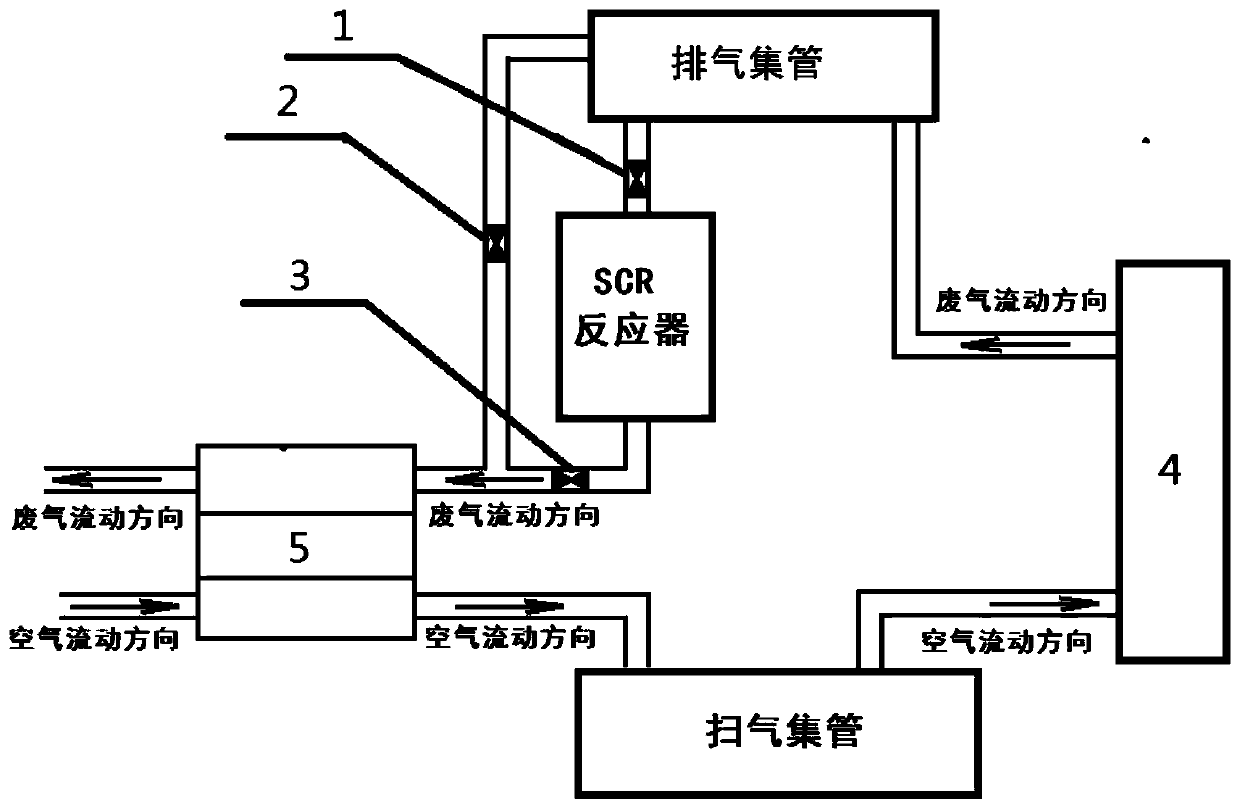

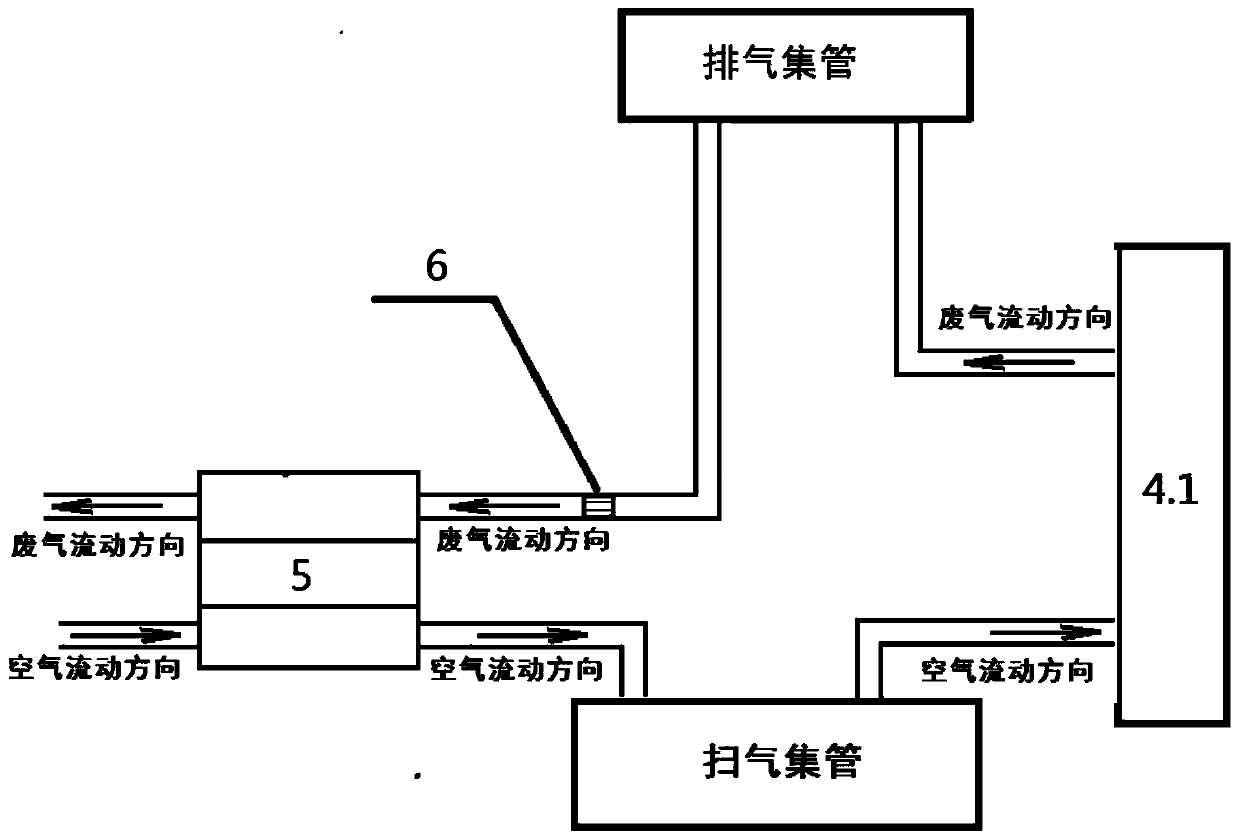

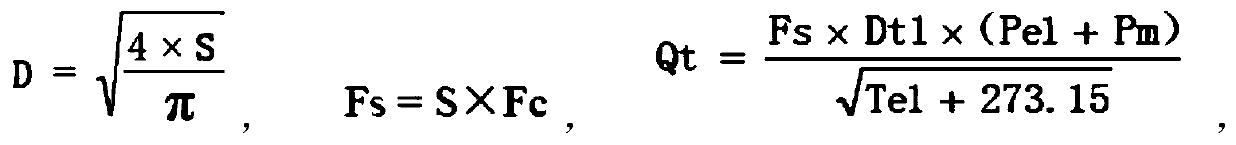

[0046] The following further analyzes the role of the HPSCR device in the Tier III condition of the diesel engine and its impact on the performance parameters of the diesel engine. When the diesel engine is running in Tier III conditions, such as figure 1 As shown, the HPSCR exhaust gas entry control valve 1 and the HPSCR exhaust gas discharge control valve 3 are opened, the supercharger exhaust gas entry control valve 2 is closed, and the diesel engine exhaust gas enters the supercharger 5 after undergoing selective catalytic reduction reaction in the HPSCR device. When the diesel engine exhaust gas passes through the HPSCR device, there will be exhaust energy and pressure loss in the diesel engine exhaust gas. Sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com