Centrifugal water pump

A centrifugal and water pump technology, used in non-displacement pumps, non-displacement pumps, rotary piston pumps, etc., can solve the problems of straining the cylinder wall, reducing the efficiency of the plunger pump, and high cost, saving energy. Consumption, improve stability, high self-priming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

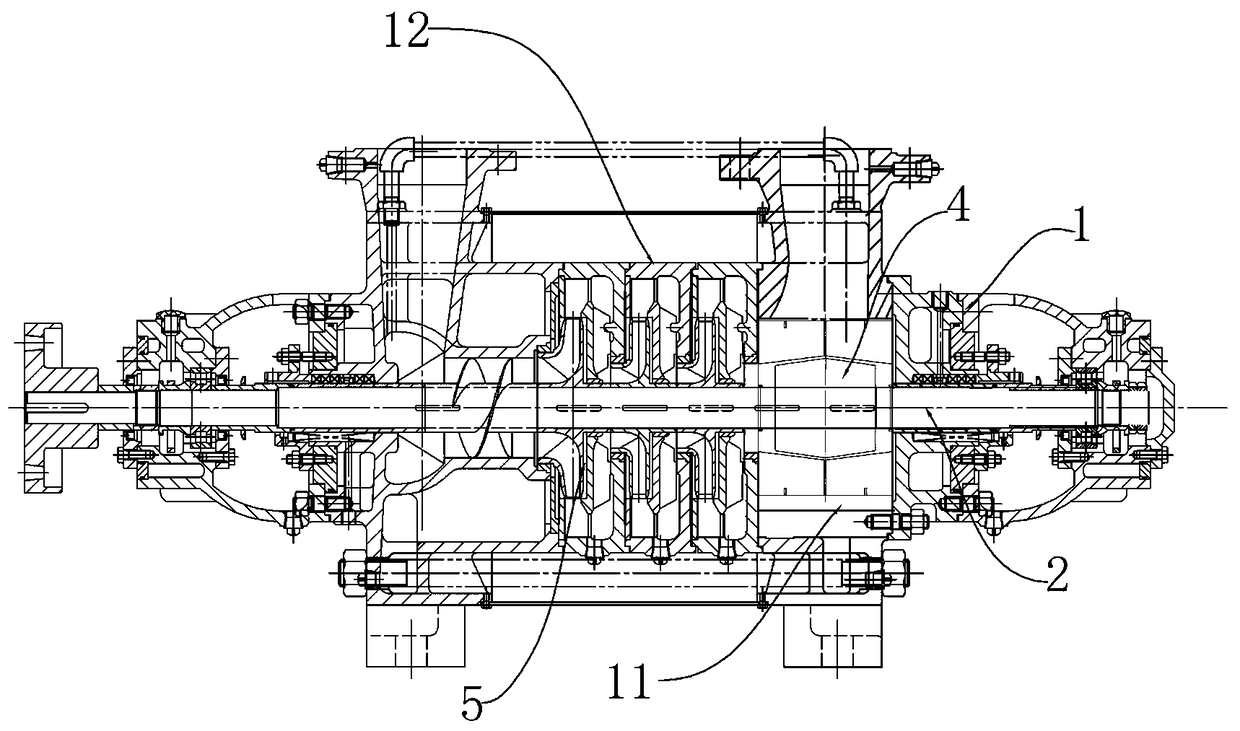

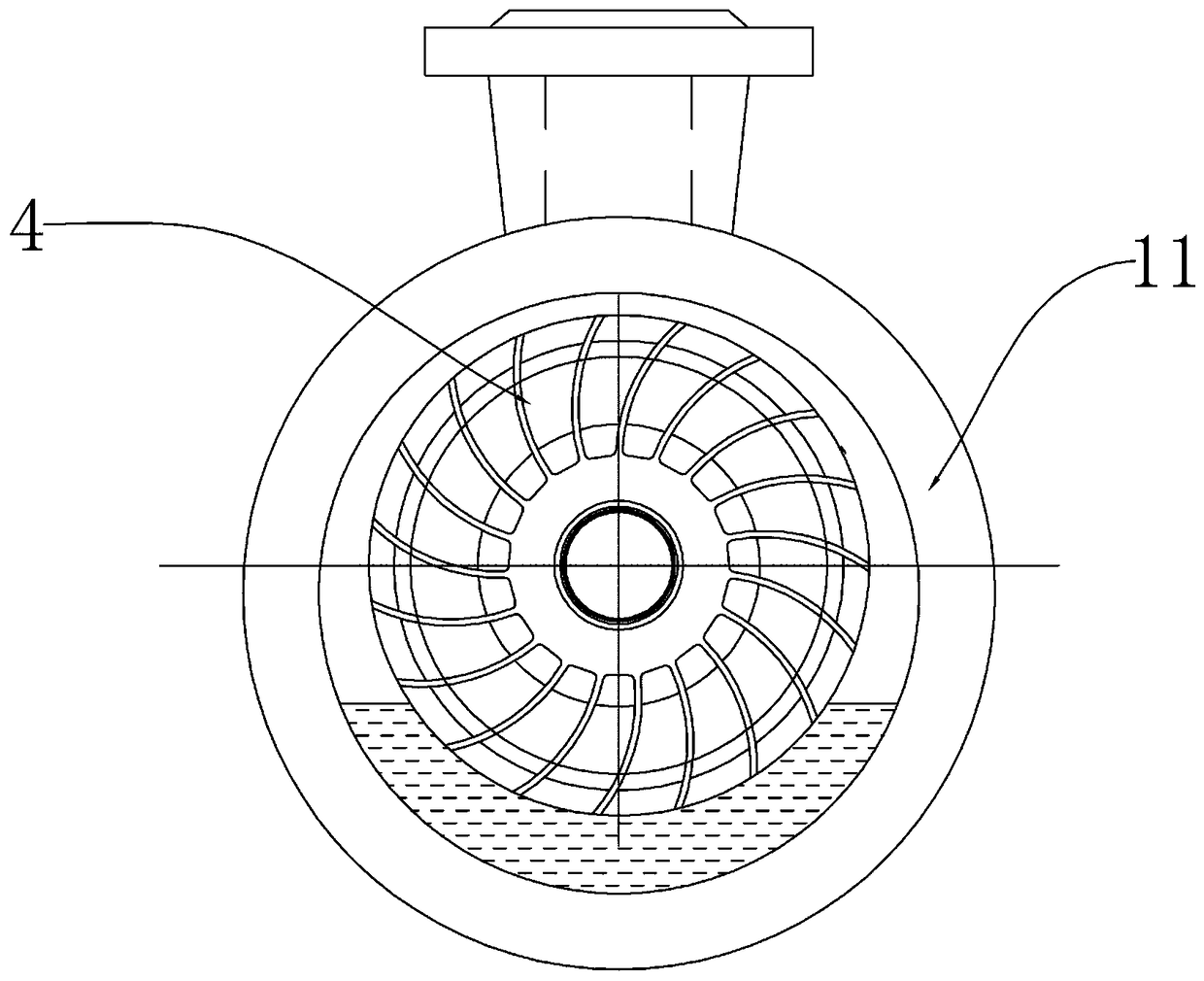

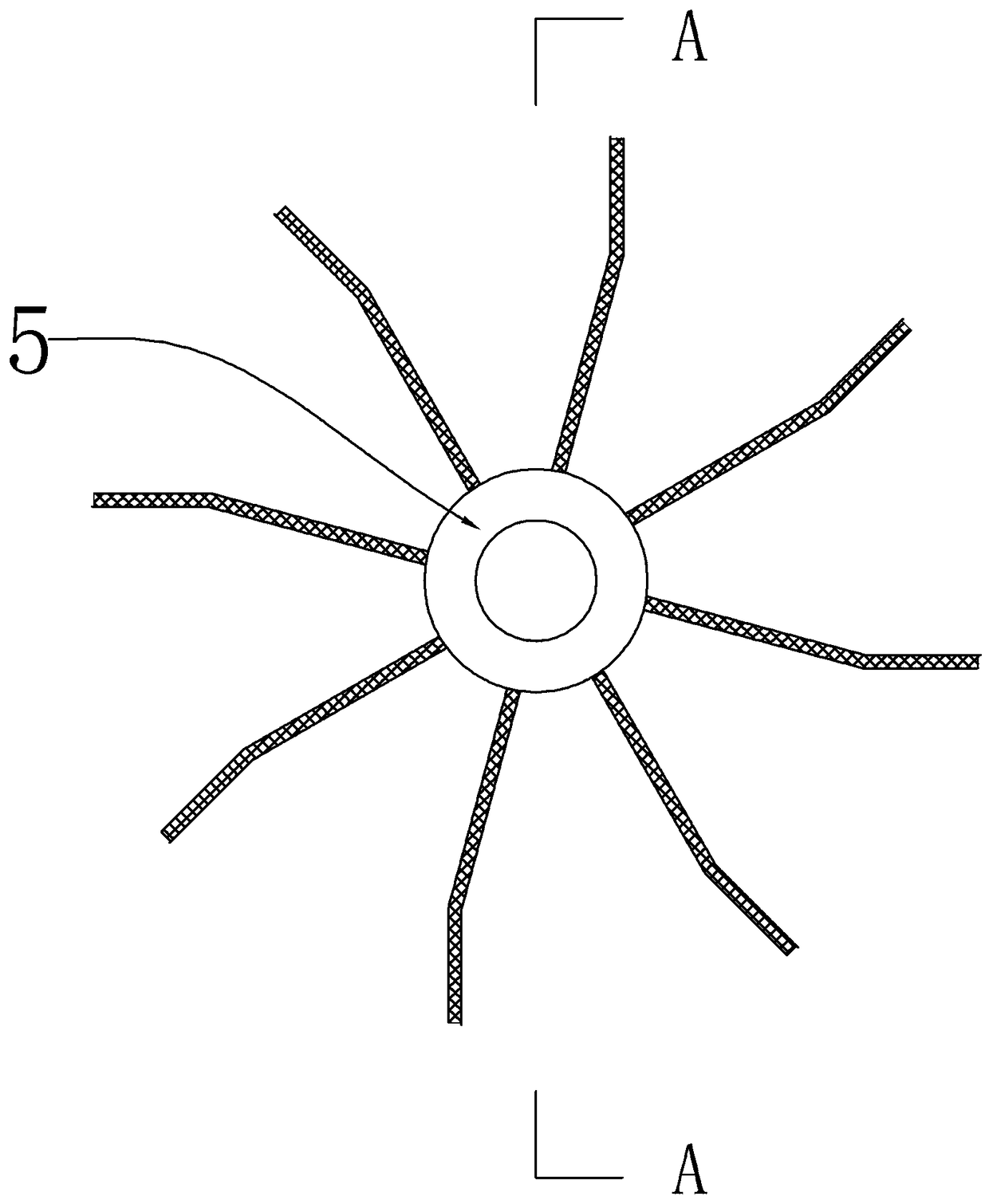

[0017] Such as figure 1 , a centrifugal water pump, comprising a pump casing 1 and a pump shaft 2 rotatably mounted on both ends of the pump casing through bearings, one end of the pump shaft protrudes outside the pump casing, and a connecting part connected to a power input device is installed on the extended section, The connecting part can be a flange 3, such as figure 1 . The pump casing 1 is divided into two connected sections, the front section is the pump volute 11, and the rear section is the segmental pump casing 12; the eccentric rotor 4 with fixed blades is installed in the pump volute; the segmental pump casing is installed with Semi-open tangent impeller 5, the semi-open tangent impeller has a radial structure from the blade to the center of rotation, such as image 3 , Figure 4 .

[0018] In order to improve the efficiency of impeller operation and reduce flow resistance, the impeller can be rotated 15° towards the tangential direction, such as image 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com