Internal combustion engine nitrogen oxide efficient control system and working method thereof

A nitrogen oxides and control system technology, applied in the field of SCR flue gas denitrification, to achieve the effect of mature technology, reasonable structure, low cost of transformation and operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0019] Example.

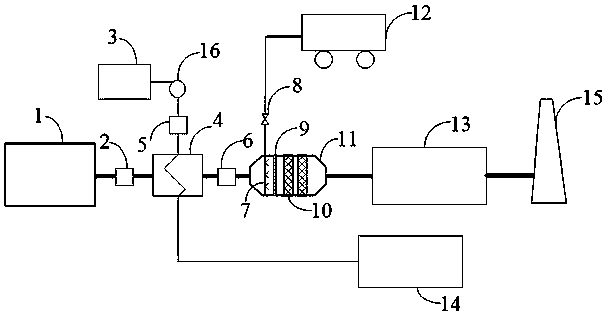

[0020] see figure 1 , a high-efficiency control system for nitrogen oxides in an internal combustion engine, comprising an internal combustion engine 1, a No. 1 temperature sensing device 2, a water storage tank 3, a heat exchanger 4, a flow control valve 5, a No. 2 temperature sensing device 6, and an ammonia injection grid 7 , reducing agent flow control valve 8, rectifying grid 9, catalyst layer 10, SCR reactor 11, reducing agent storage tank 12, flue gas type lithium bromide unit 13, steam type lithium bromide unit 14, chimney 15, water pump 16.

[0021] The internal combustion engine 1, the heat exchanger 4, the SCR reactor 11, the flue gas type lithium bromide unit 13 and the chimney 15 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com