Prefabricated concrete column and column assembly connection node fabrication and installation method

A technology of prefabricated concrete and connecting nodes, which is applied in the direction of columns, pillars, pier columns, etc., can solve the problems of easy occurrence of sandwich layers, difficulty in guaranteeing construction quality, and slow construction speed, so as to achieve convenient connection quality, controllable component quality, The effect of quick construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

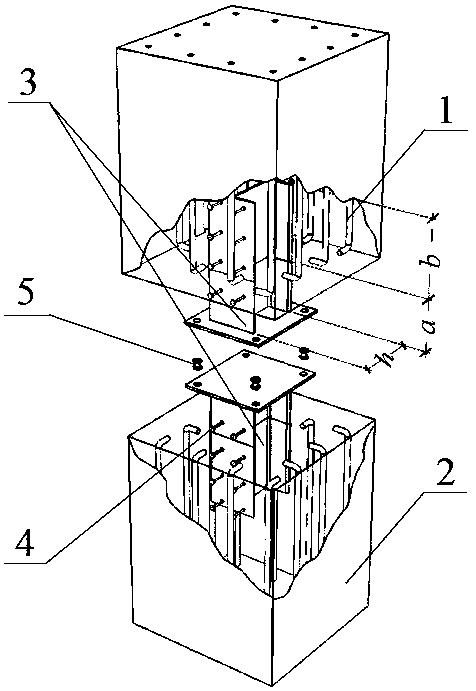

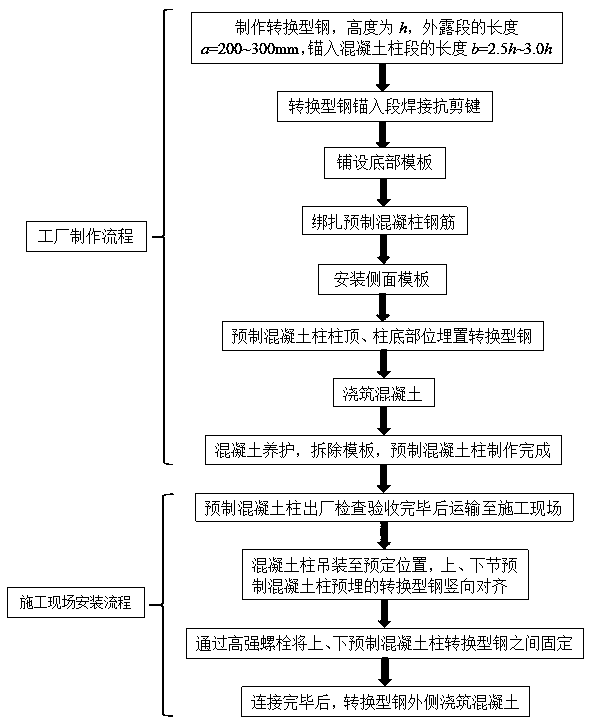

[0025] The fabrication and installation method of prefabricated concrete columns and prefabricated concrete columns, including the upper precast concrete column 1, the lower precast concrete column 2, the conversion steel 3, the shear key 4, and the high-strength bolt 5. The precast concrete columns are first fabricated in a factory and then transported to the construction site for installation.

[0026] The fabrication and installation method of the prefabricated concrete column and the column assembly type connection node includes the following steps:

[0027] The first step is to make the conversion steel 3, the height is h, the length of the exposed section is a, the length of the anchored concrete column section is b, the end of the exposed section of the conversion steel 3 is welded with a steel plate, and a bolt hole is opened on the steel plate;

[0028] In the second step, the shear key 4 is welded according to the design on the anchoring section of the conversion sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com