Underground structure anti-floating system and construction method thereof

An underground structure and system technology, applied in the direction of infrastructure engineering, protection devices, buildings, etc., can solve the problems of cracking and water seepage of underground structures, arching or floating of underground structures, affecting the normal use of underground structures, etc., so as to improve the anti-floating performance. , the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

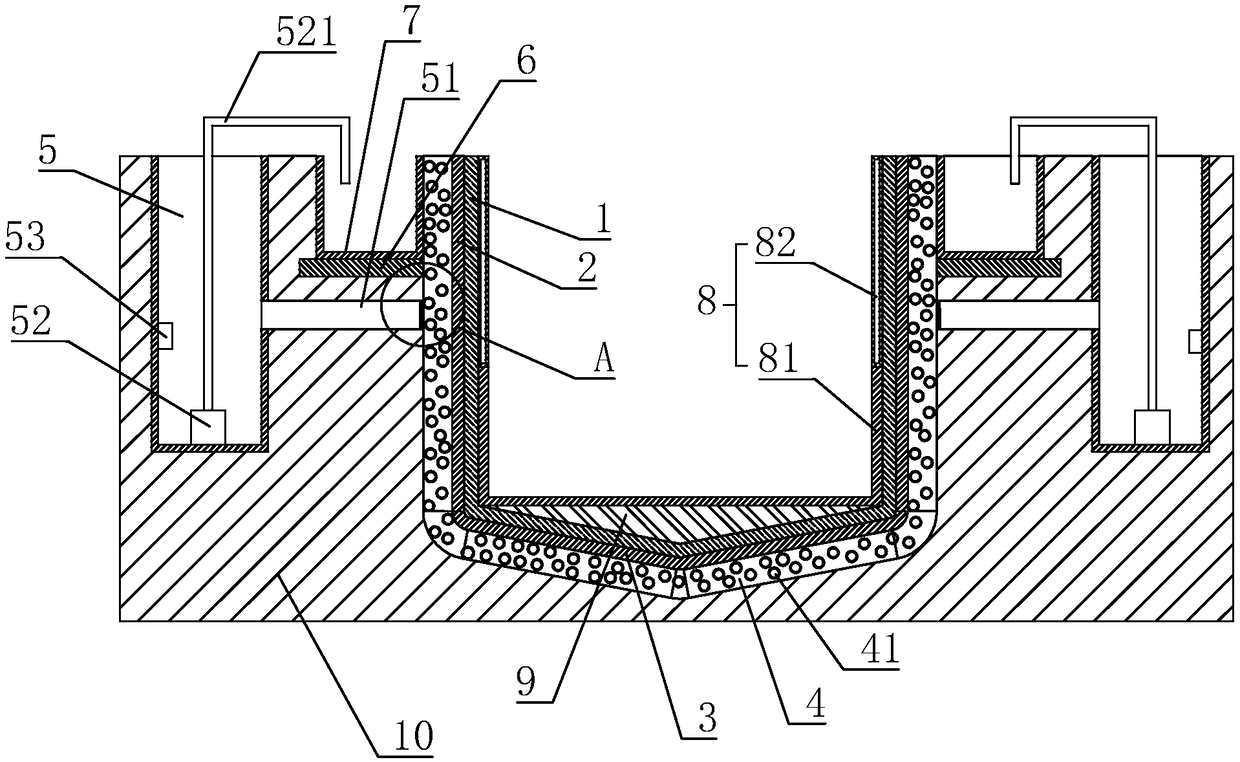

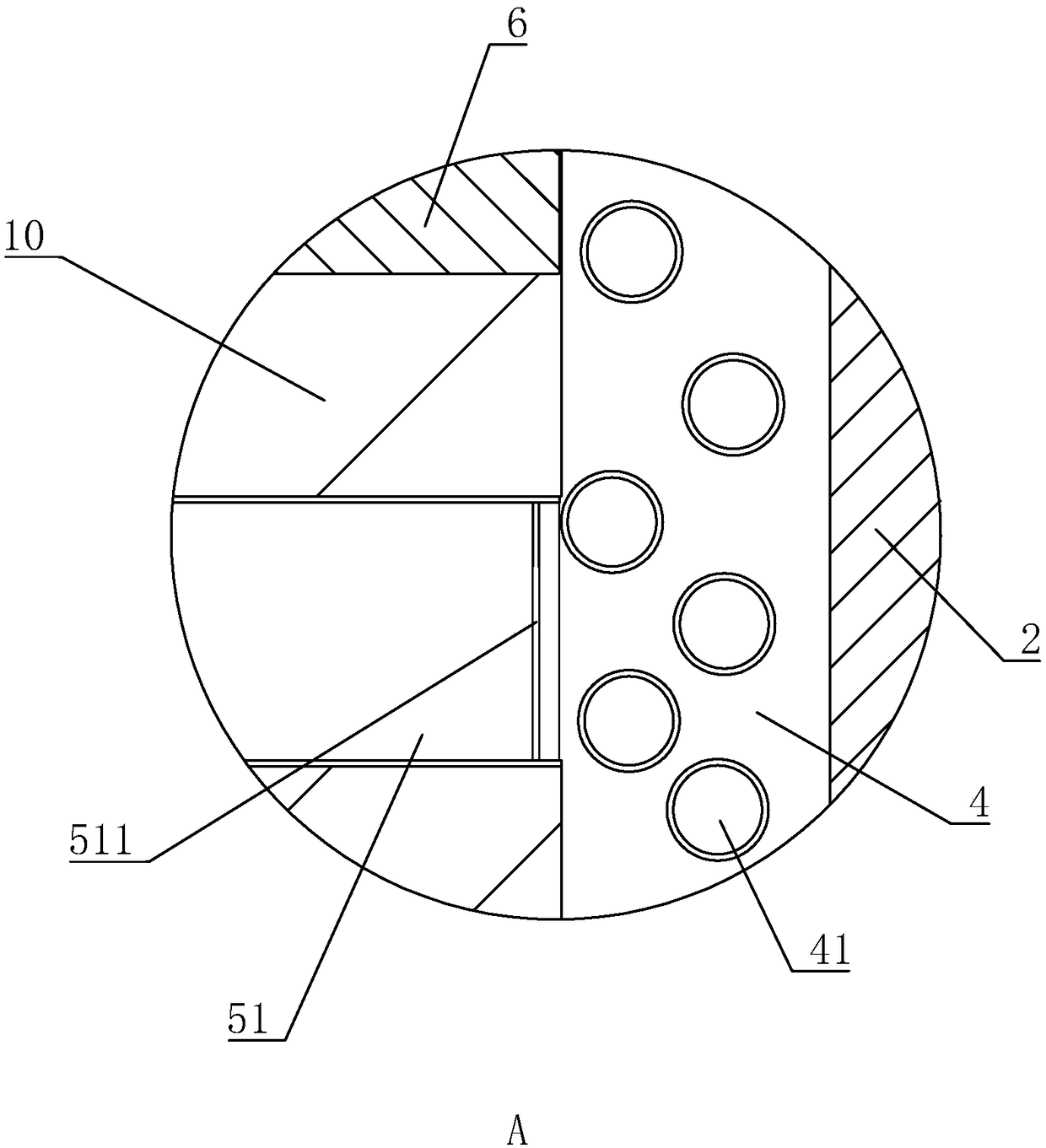

[0035] Embodiment 1: a kind of underground structure anti-floating system, such as figure 1 , including the foundation pit 1, and also includes several vertical retaining piles 2 arranged along the periphery of the foundation pit 1, each vertical retaining pile 2 is adjacent to each other and forms a protective pile wall, so as to protect the periphery of the foundation pit 1 and reduce the The foundation pit 1 is subjected to the pressure of the soil body 10 . The bottom of the foundation pit 1 is provided with a number of cable-stayed piles 3 embedded in the soil 10. The cable-stayed piles 3 are arranged obliquely downward and the lower end extends to the middle of the foundation pit 1. In this embodiment, the inclination of the cable-stayed piles 3 is set is 30°. The higher end of the cable-stayed pile 3 is connected to the bottom of the vertical guard pile 2, and the vertical guard pile 2 and the cable-stayed pile 3 are all pierced with steel cages to improve the structur...

Embodiment 2

[0041] Embodiment 2: a kind of construction method that is used for the anti-floating system of underground structure in embodiment 1, comprises the following steps:

[0042] The operator first uses the excavator to excavate the soil 10 to form the required foundation pit 1, and then drills a number of cable-stayed holes slanting downward toward the middle of the foundation pit 1 at the bottom of the foundation pit 1 along the periphery of the foundation pit 1. Put steel reinforcement cage inside, and pour concrete to form cable-stayed pile 3. Afterwards, the bottom of the foundation pit 1 is excavated and filled with fine sand to form a buffer layer 9, and the upper surface of the buffer layer 9 is filled with soil to re-form the bottom of the foundation pit 1.

[0043] Then backfill a layer of soil body 10 to the inner side wall of the foundation pit 1, and fill the bottom of the foundation pit 1 and the middle and lower parts of the side wall of the foundation pit 1 with gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com