Pipe gallery anchor core mold pressing and fixing device

A technology for stabilizing devices and anchors, applied in water conservancy projects, artificial islands, sheet pile walls, etc., can solve the problems of affecting the compaction effect, limited length of steel cables, and increasing costs, etc., to achieve reasonable design, convenient use, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

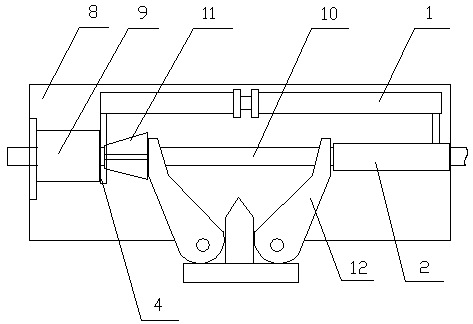

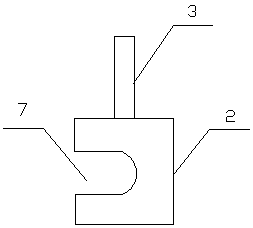

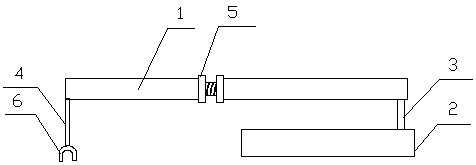

[0014] As shown in the figure, a mandrel pressing and stabilizing device for a pipe gallery anchorage according to the present invention includes an adjustment frame 1, a support block 2, a connecting rod 3, and a limit rod 4. The adjustment frame 1 is divided into two sections, front and rear. , the length adjustment nut 5 is arranged between the front and rear joints, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com