Preparation process of imitated tencel style fabric

A preparation process and fabric technology, applied in the field of textile printing and dyeing, can solve the problems of complex printing and dyeing process difficulty of TR fabric, hand feeling and style not as good as Tencel fabric, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

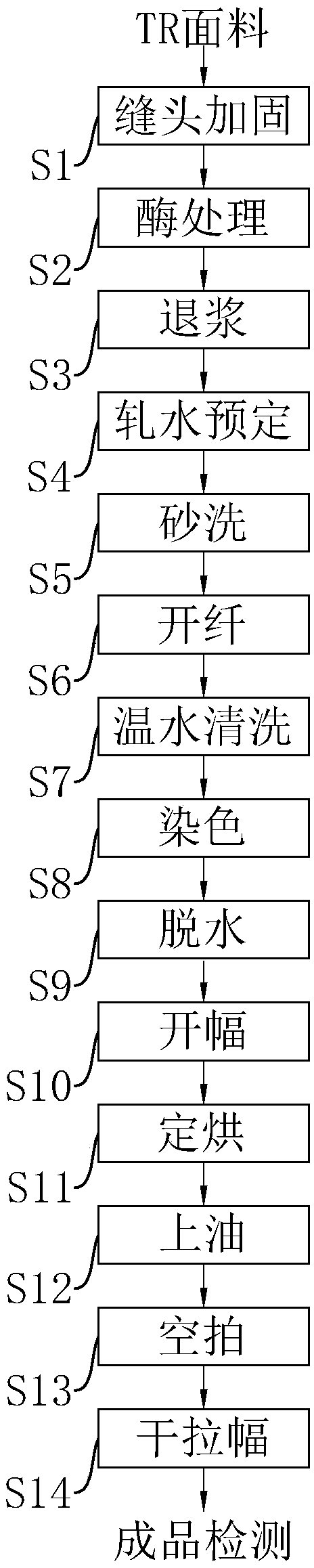

[0058] Reference figure 1 , A preparation process of imitation Tencel style fabric, the TR fabric is processed in the following steps:

[0059] S1: Seam head reinforcement.

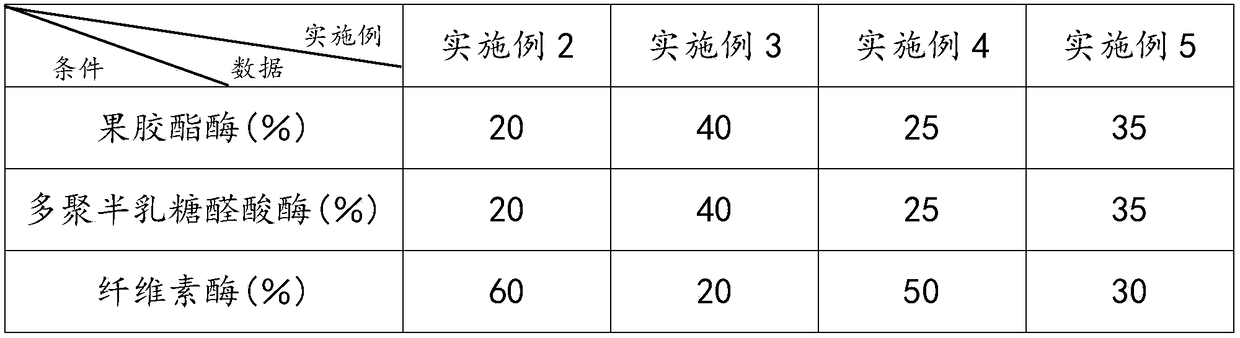

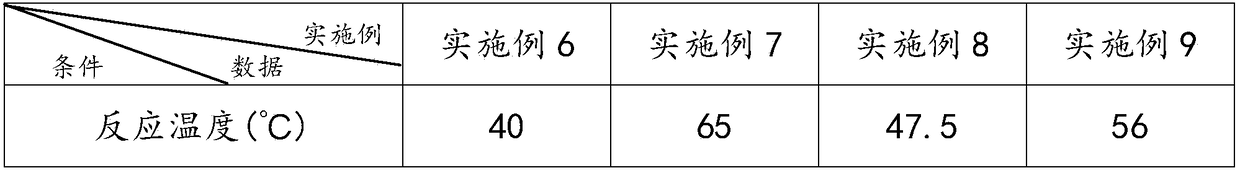

[0060] S2: Enzyme treatment is performed on the TR fabric with the above seam reinforcement. Put the prepared TR fabric into a container containing various enzymes, soak for 3 hours, and then dissolve and remove some impurities it originally contained. The enzyme contained in the container and its mass percentage are: 30% pectin esterase, 30% polygalacturonase and 40% cellulase. The reaction temperature is 52.5°C, and the pH is controlled by pH. In 5.2.

[0061] S3: Desizing the TR fabric after the above enzyme treatment, adding desizing agent C in the desizing tank 15 H 31 O(CH 2 OCH 2 ) 15 H; Put the TR fabric in and add C 15 H 31 O(CH 2 OCH 2 ) 15 Desizing in the desizing tank of H, desizing agent C 15 H 31 O(CH 2 OCH 2 ) 15 The amount of H added is 8g / L.

[0062] S4: Pre-roll the TR fabric after desizing; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com