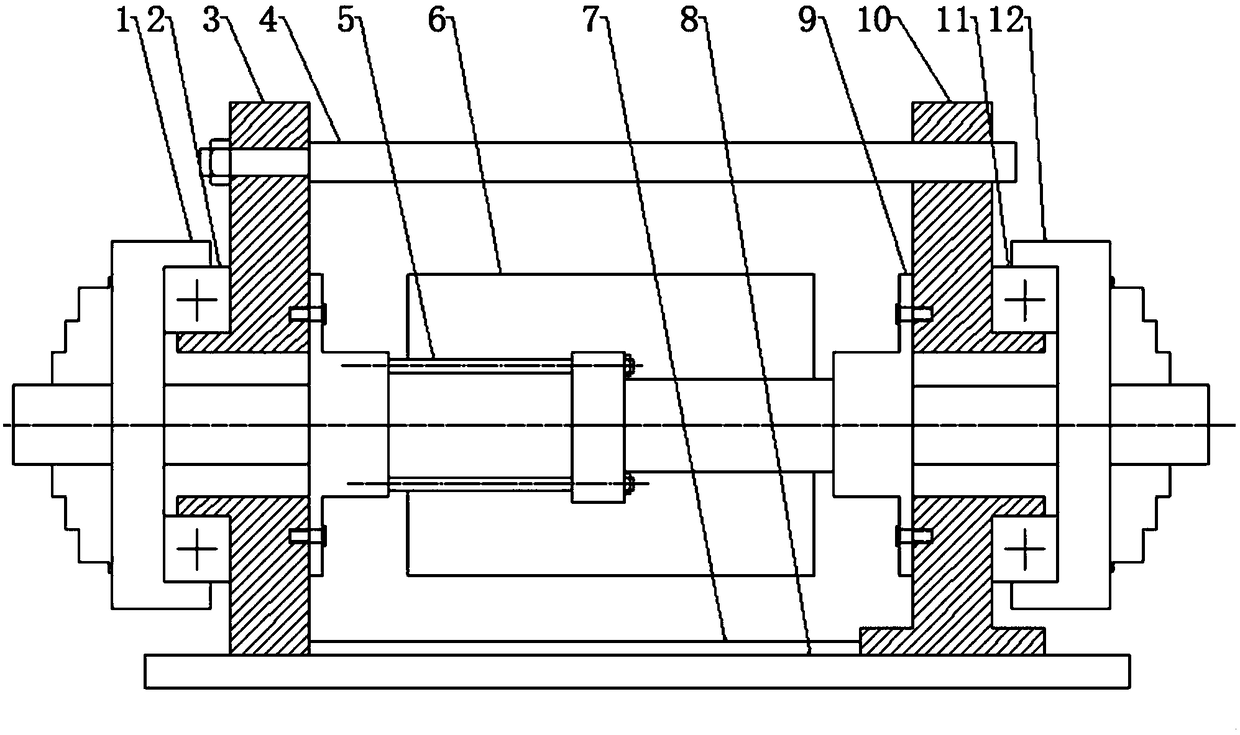

Prestressed laser cladding crack suppressing method and device of shaft sleeve part

A laser cladding and suppression device technology, which is applied in the coating process of metal materials, coating, etc., can solve the problem that the size of the prestress cannot be accurately controlled, and the rotary motion of shaft sleeve parts cannot be satisfied, and the efficiency and effect are limited. and other problems to achieve the effect of reducing the occurrence of cracks in the cladding layer, reducing the possibility and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

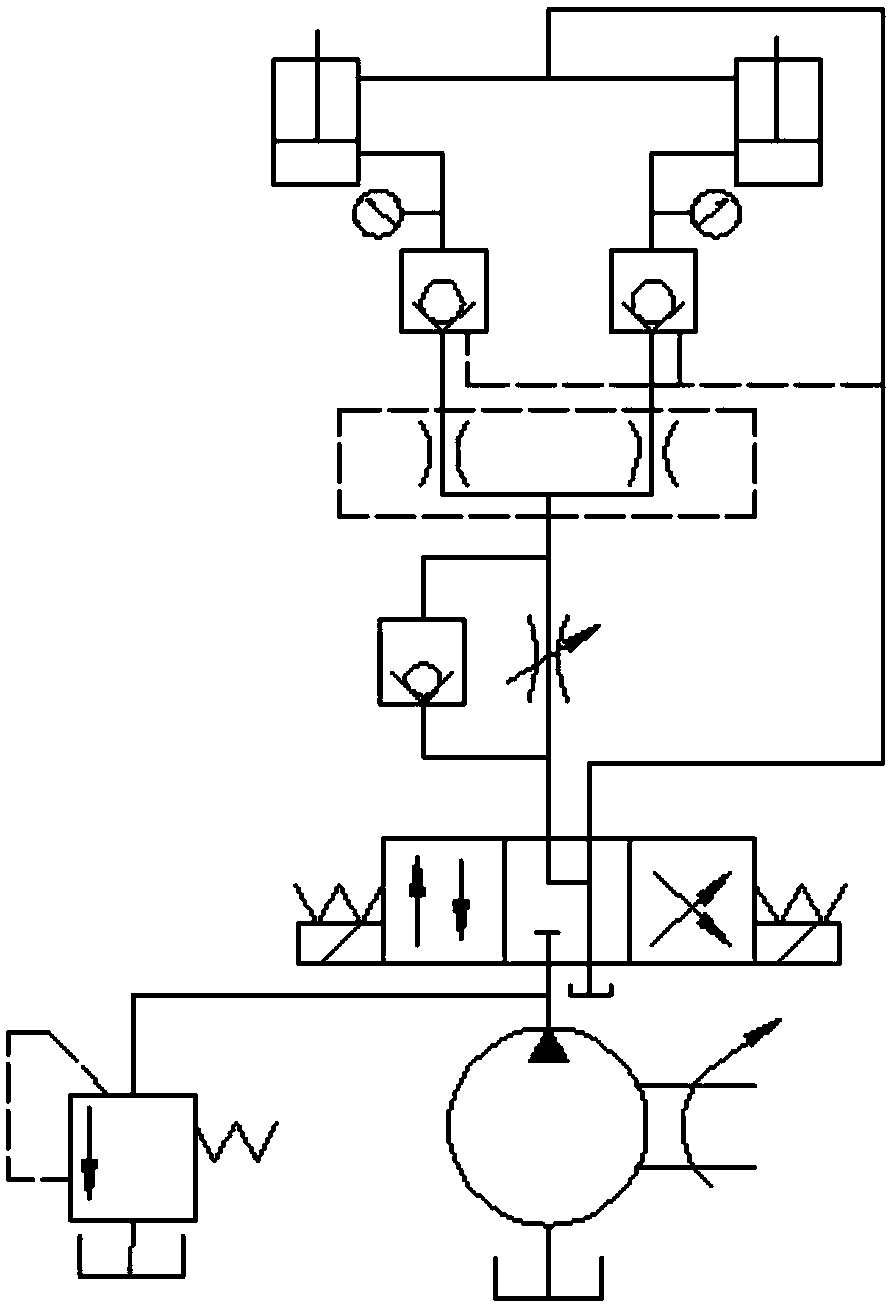

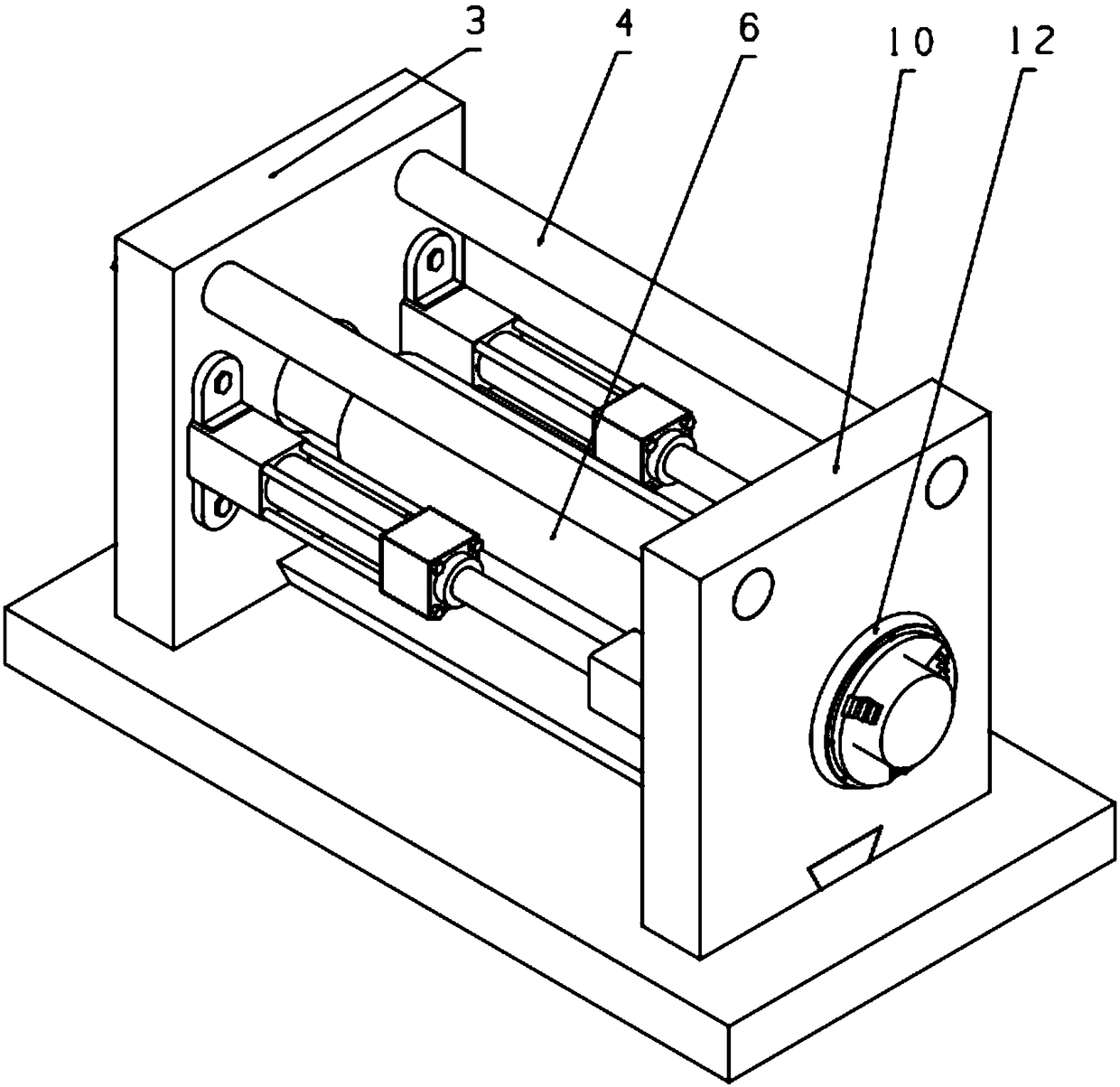

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 The material of shaft sleeve parts is 35CrMo steel; first, confirm the elastic limit strength of the processed 35CrMo material.

[0020] Example 1 Then, an axial tensile stress is applied to the sleeve part on the prestressed laser cladding crack suppression device, and the corresponding prestress is measured and calculated by the electric resistance strain gauge method, and the conversion ensures that the workpiece material is still in the in an elastic state.

[0021] Embodiment 1 Next, under the condition of maintaining the prestress, the laser cladding crack suppression device with prestress is placed on the laser cladding equipment, and the shaft sleeve parts are treated with the Zhongke Sixiang LDM3000-100 laser Carry out prestressed laser cladding, during laser cladding, the magnitude and direction of the applied prestress remain unchanged, the scanning speed is 4mm / s, the power is 2.5KW, the delivery rate is 0.1g / s, the spot diameter is 5mm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com