Preparation method of dry pink strawberry wine

A technology for strawberry wine and rosé, which is applied in the field of preparation of dry rosé strawberry wine, can solve the problems of insufficient aftertaste, unacceptable to consumers, weak taste and the like, and achieves the effect of solving the sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

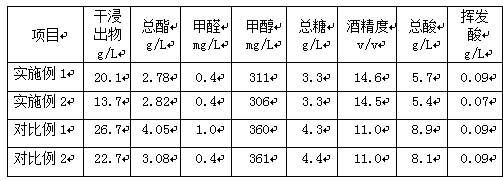

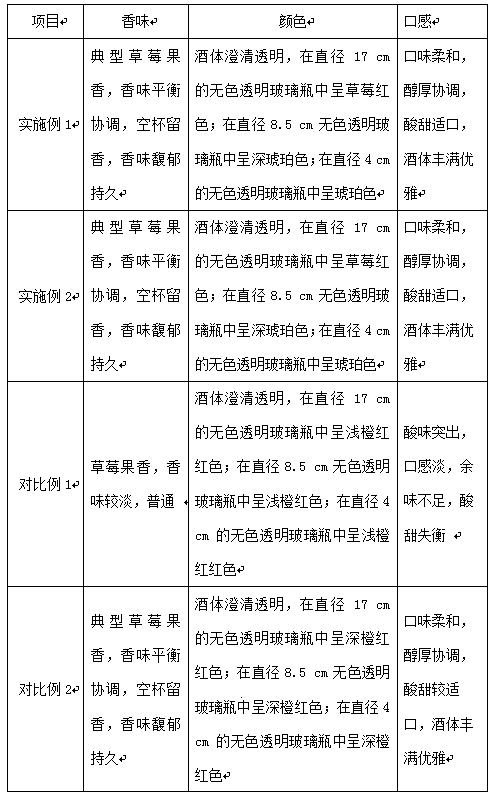

Examples

Embodiment 1

[0016] (1) Cleaning: Select ripe and complete fresh strawberries, remove calyx, wash with water, soak in salt solution with a mass concentration of 1.8% for 30 minutes, then soak in clean rice washing water for 15 minutes, and then place Drain in clean water to wash the strawberries, break them, and separate the juice residue; (2) Blending: use the dilution acid drop method and ingredient blending treatment to blend the ingredients of the strawberry pulp to ensure a suitable acid value and sugar content. Carry out natural fermentation; (3) Main fermentation: The fermentation temperature is controlled at 25°C, stirred twice a day, and the main fermentation period is 7 days; (4) Filtration: After filtering the fermentation slurry, add seaweed polysaccharide and salt, stir evenly, and place in 1 Stand at ℃ for 3 days, take out and filter the fermented liquid roughly; (5) post-fermentation: put the filtrate into another sterilized fermenter, add a fermentation plug, seal with water...

Embodiment 2

[0021] (1) Cleaning: Select ripe and complete fresh strawberries, remove calyx, wash with water, soak in salt solution with a mass concentration of 1.8% for 30 minutes, then soak in clean rice washing water for 15 minutes, and then place Drain in clean water to wash the strawberries, break them, and separate the juice residue; (2) Blending: use the dilution acid drop method and ingredient blending treatment to blend the ingredients of the strawberry pulp to ensure a suitable acid value and sugar content. Carry out natural fermentation; (3) Main fermentation: The fermentation temperature is controlled at 20°C, stirred twice a day, and the main fermentation period is 7 days; (4) Filtration: After filtering the fermentation slurry, add seaweed polysaccharide and salt, stir evenly, and place in 1 Stand at ℃ for 3 days, take out and filter the fermented liquid roughly; (5) post-fermentation: put the filtrate into another sterilized fermenter, add a fermentation plug, seal with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com