Special anti-oxidation lubricating coating for hot stamping, and preparation method and application thereof

A hot stamping and anti-oxidation technology, used in fire-resistant coatings, coatings, etc., can solve the problems of wear and tear, product oxidation, etc., to reduce wear and tear, reduce damage, and enhance formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

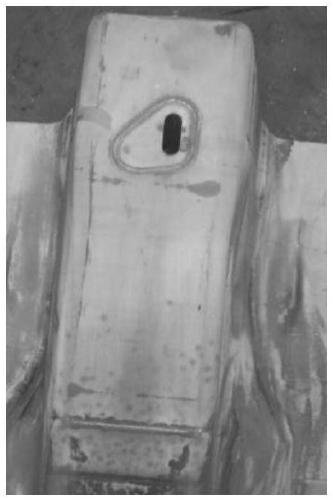

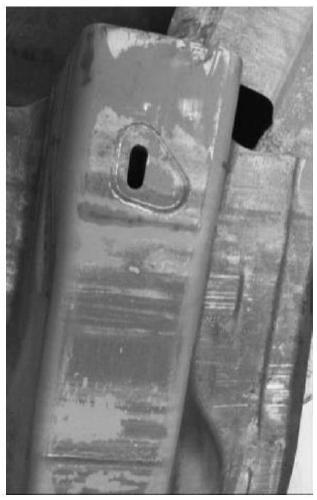

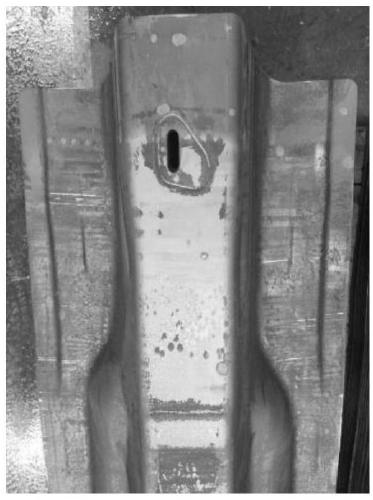

Image

Examples

Embodiment 1

[0032] According to hexagonal boron nitride powder 30%, sodium boron bentonite (thickener) 5%, polyvinyl alcohol (dispersant) 2%, DF-8025 defoamer 0.5%, LF-1207 alcohol amine rust inhibitor 1.2 %, the balance is water, and the components are proportioned and weighed. First, add the dispersant, thickener, antirust agent, and defoamer to the solvent, and use ultrasonic waves to make them fully mixed and dissolved, and then hexagonal boron nitride Add it, and use ultrasonic waves to mix and dissolve evenly to obtain the special anti-oxidation lubricating coating for hot stamping. The particle size distribution of the hexagonal boron nitride powder is 1-3 μm, and the purity is 99.6%.

[0033] Spray the above-mentioned anti-oxidation lubricating coating specially for hot stamping on the sheet evenly with spraying equipment, the spray thickness is 20 μm, dry it in a furnace at 300°C and keep it warm for 30s-50s, take out the sheet and heat it on the thermoforming equipment For form...

Embodiment 2

[0035] 40% hexagonal boron nitride powder, 15% organic boron bentonite (thickener), 15% polyethylene glycol (dispersant), 1.0% DT-135 industrial defoamer, 2% acetylene glycol rust inhibitor , and the balance is ethanol, and the proportion of each component is weighed. First, add the dispersant, thickener, antirust agent, and defoamer to the solvent, and use ultrasonic waves to fully mix and dissolve them evenly, and then add hexagonal boron nitride. Wherein, ultrasonic waves are used to fully mix and dissolve evenly to obtain the special anti-oxidation lubricating coating for hot stamping. The particle size distribution of the hexagonal boron nitride powder is 3-10 μm, and the purity is 99.6%.

[0036] Spray the above-mentioned special anti-oxidation lubricating coating for hot stamping evenly on the sheet with a spraying equipment, the spraying thickness is 30 μm, dry it in a furnace at 200°C and keep it warm for 30s-50s, take out the sheet and heat it on the thermoforming eq...

Embodiment 3

[0037] Embodiment 3 comparative experiment

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com