Flame-retardant, smoke-suppressing and environmentally-friendly PVC low foaming board and production method thereof

A low-foaming and environmentally friendly technology, applied in the field of plastic sheets and their processes, can solve the problems of large influence of the processing technology of flame retardant and smoke suppressant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

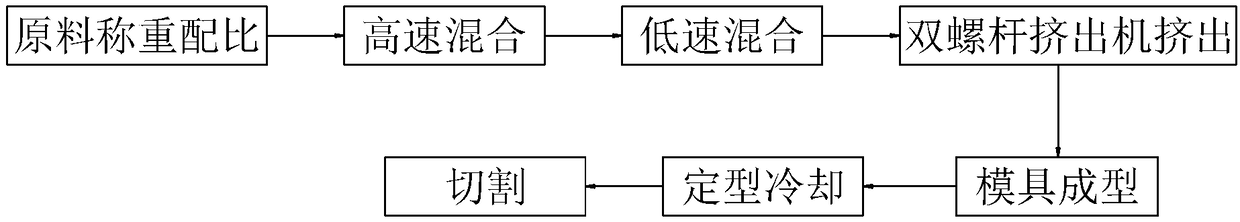

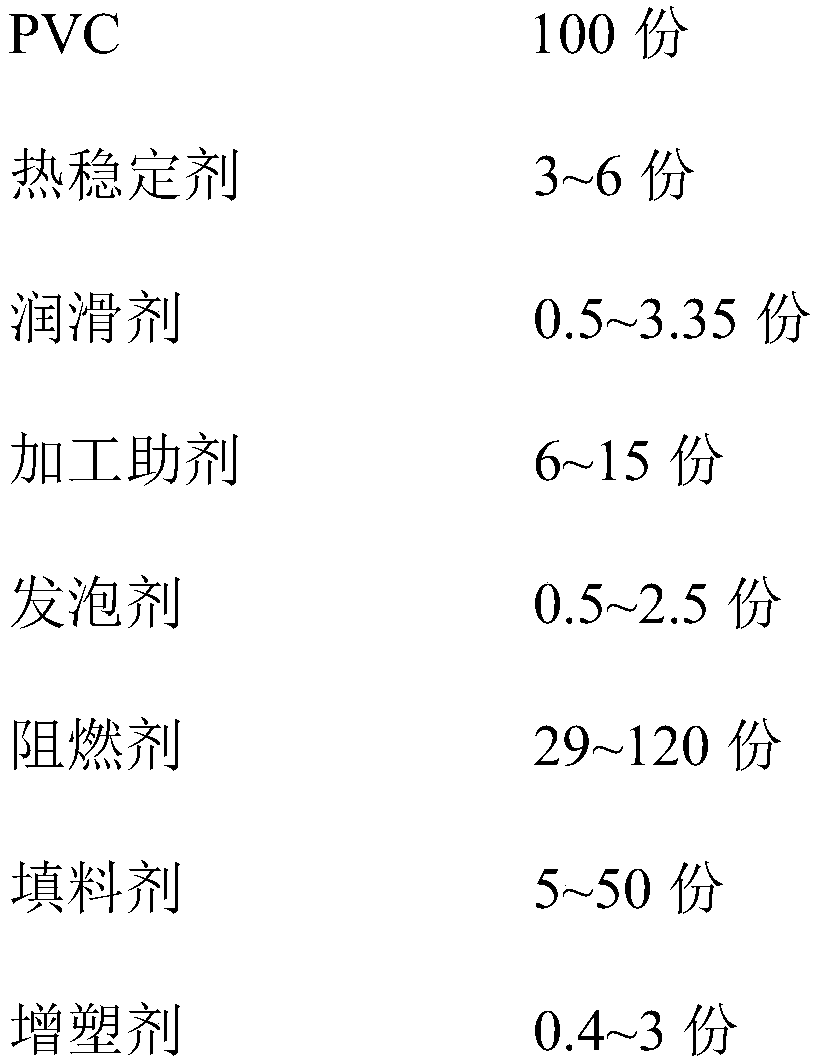

[0035] The present invention also provides a method for preparing flame-retardant, smoke-suppressing, environment-friendly PVC low-foaming board, which is used to prepare the flame-retardant, smoke-suppressing, environment-friendly PVC low-foaming board, see figure 1 , the preparation method of the flame-retardant smoke-suppressing environment-friendly PVC low-foaming board comprises the following steps:

[0036] Step 1: Weigh zinc borate, ammonium octamolybdate and environmentally friendly non-toxic compounds in PVC, heat stabilizer, lubricant, processing aid, foaming agent, filler, plasticizer and flame retardant by weight of the raw materials. Antimony flame retardant;

[0037] Step 2: put the raw materials weighed in step 1 into a high-speed mixing device, stir at a temperature of 90-120°C for 10-20min, and the stirring speed is 1600-2650r / min;

[0038] Step 3: Put the high-speed mixed raw materials into the low-speed mixing device, weigh magnesium hydroxide and aluminum ...

Embodiment 1

[0044] This embodiment provides a flame-retardant, smoke-suppressing, environmentally friendly PVC low-foaming board, which includes: 100 parts of PVC, 5.6 parts of calcium-zinc stabilizer, 1 part of G60, 1 part of stearic acid, and 1.35 parts of polyethylene wax in parts by weight , 15 parts of methyl methacrylate, 2.5 parts of azodicarbonamide, 18 parts of zinc borate, 45 parts of aluminum hydroxide, 15 parts of magnesium hydroxide, 10 parts of ammonium octamolybdate, 8 parts of environmentally friendly antimony-free flame retardant, 2 parts epoxy soybean oil and 5 parts modified light calcium carbonate.

[0045] After weighing zinc borate, ammonium octamolybdate and environmentally friendly antimony-free flame retardant in PVC, heat stabilizer, lubricant, processing aid, foaming agent, filler, plasticizer and flame retardant Put it into a high-speed mixing device, stir at 120°C for 10 minutes, and the stirring speed is 1980r / min; put the high-speed mixed raw materials into ...

Embodiment 2

[0052] This embodiment provides a flame-retardant, smoke-suppressing, environment-friendly PVC low-foaming board, which includes in parts by weight: 100 parts of PVC, 4 parts of calcium zinc stabilizer, 0.3 part of G60, 0.3 part of stearic acid, 0.4 part of polyethylene wax, 6 parts of methyl methacrylate, 0.6 parts of azodicarbonamide, 8 parts of zinc borate, 30 parts of aluminum hydroxide, 10 parts of magnesium hydroxide, 5 parts of ammonium octamolybdate, 10 parts of environmental protection antimony-free flame retardant, oxidation 0.6 parts of polyethylene wax and 40 parts of modified light calcium carbonate.

[0053] After weighing zinc borate, ammonium octamolybdate and environmentally friendly antimony-free flame retardant in PVC, heat stabilizer, lubricant, processing aid, foaming agent, filler, plasticizer and flame retardant Put it into a high-speed mixing device, stir at 120°C for 10 minutes, and the stirring speed is 1980r / min; put the high-speed mixed raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com