Uracil maleamic polyol ester and preparation method and application thereof

A technology of maleamic acid and polyol ester, applied in organic chemistry and other directions, can solve the problems of insufficient thermal stability and durability, and achieve the effects of inhibiting degradation and coloring, simple preparation method and improving precipitation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

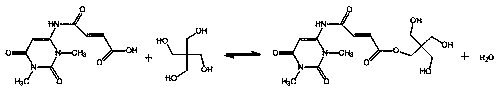

[0035] A kind of 1,3-dimethyl-6 aminouracil pentaerythritol maleamic acid ester, its preparation method is as follows:

[0036] S1. Take 24.5g (0.25mol) of maleic anhydride and pour it into a 500ml three-neck round bottom flask, stir and heat up to 60°C, and pass nitrogen gas. After it melts, add 38.8g (0.25mol) of 1,3-dimethyl -6-aminouracil, the intermediate 1,3-dimethyl-6-aminouracil maleamic acid

[0037] ,

[0038] Wherein the amidation reaction temperature is 70°C, the reaction time is 4h, and the molar ratio of maleic anhydride to 1,3-dimethyl-6-aminouracil is 1:1;

[0039]S2. Add 20.5g (0.15mol) of pentaerythritol and 38g (0.15mol) of 1,3-dimethyl-6-aminouracil maleamic acid into a 250ml three-necked round-bottomed flask, and add 0.8g (2.2% of polyol) ) Titanium sulfate, the titanium sulfate has been roasted at 500°C for 3 hours, heated to reflux to separate water, and the product obtained from the esterification reaction under sufficient stirring is 1,3-dimethyl-6...

Embodiment 2

[0043] A kind of preparation method of 1,3-dimethyl-6 aminouracil maleamic acid polyol ester, comprises the steps:

[0044] S1. Take 24.5g (0.25mol) of maleic anhydride and pour it into a 500ml three-neck round bottom flask, stir and heat up to 60°C, and blow nitrogen gas. After it melts, add 58.2g (0.38mol) of 1,3-dimethyl -6 aminouracil, the intermediate 1,3-dimethyl-6 aminouracil maleamic acid,

[0045] Wherein the amidation reaction temperature is 90°C, the reaction time is 3h, and the molar ratio of maleic anhydride to 1,3-dimethyl-6-aminouracil is 1:1.5;

[0046] S2. Add 15.66g (0.115mol) of pentaerythritol and 38g (0.15mol) of 1,3-dimethyl-6-aminouracil maleamic acid into a 250ml three-necked round-bottomed flask, and add 0.6g (0.0025mol) of titanium sulfate , the titanium sulfate has been roasted at 500°C for 3 hours, heated to reflux to separate water, and the product obtained from the esterification reaction under sufficient stirring is 1,3-dimethyl-6-aminouracil ma...

Embodiment 3

[0049] A kind of preparation method of 1,3-dimethyl-6 aminouracil maleamic acid polyol ester, comprises the steps:

[0050] S1. intermediate 1,3-dimethyl-6 aminouracil maleamic acid is obtained according to the method of embodiment 1;

[0051] S2. Add 18.5g (0.136mol) of pentaerythritol and 38g (0.15mol) of 1,3-dimethyl-6-aminouracil maleamic acid into a 250ml three-necked round-bottomed flask, and add 0.7g (0.0030mol) of titanium sulfate , the titanium sulfate has been roasted at 500°C for 3 hours, heated to reflux to separate water, and the product obtained from the esterification reaction is 1,3-dimethyl-6-aminouracil maleamic acid pentaerythritol ester under full stirring.

[0052] Wherein, the esterification reaction temperature is 170° C., the reaction time is 4 hours, and the molar ratio of 1,3-dimethyl-6-aminouracil maleamic acid to pentaerythritol is 1:1.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com