Punching cutting tool

A tool and punching technology, which is applied in the field of punching tools, can solve the problems of broken tool life, waste stuck on the inner hole of the tool, and safety, and achieve high machining accuracy, reduced deformation, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

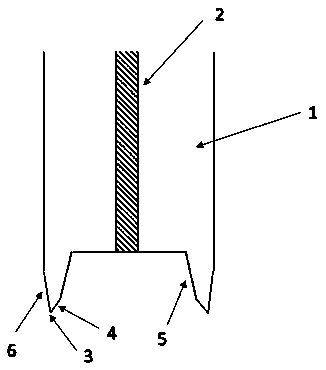

[0013] Such as figure 1 As shown, a punching tool includes a tool matrix 1, a knife tip 3, an outer edge surface 6, a knife edge surface 4 and a knife body surface 5, wherein the tool matrix 1 is a cylindrical Cr12, and there is a vent hole 2 in the middle of the tool matrix 1. The first acute angle formed by the blade surface 4 and the outer edge surface 6 is the tip 3, and the second acute angle formed by the blade surface 5 and the outer edge surface 6 of the tool is smaller than the first acute angle formed by the blade surface 4 and the outer edge surface 6. Acute angle.

[0014] Further, the acute angle formed by the blade edge surface 4 and the outer edge surface 6 is between 15-25 degrees.

[0015] Further, the acute angle formed by the blade surface 5 and the outer edge surface 6 is between 5-10 degrees.

[0016] Further, the cutti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com