An ultrasonic cutting device applied to fixed-length trimming of rubber materials

An ultrasonic and trimming technology, applied in the field of rubber materials, can solve problems such as low production efficiency and unstable quality, and achieve the effect of preventing deviation and uniform length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

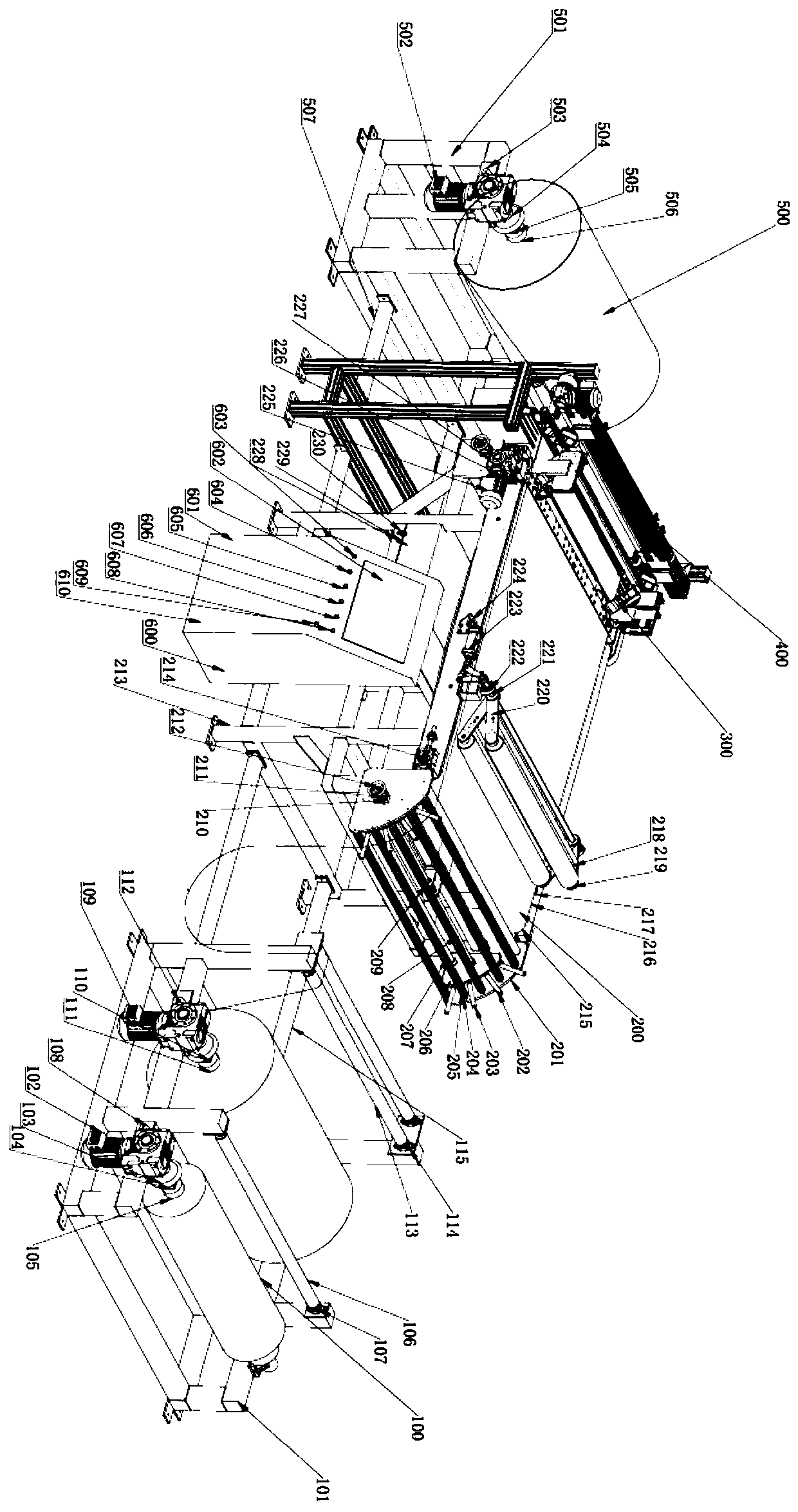

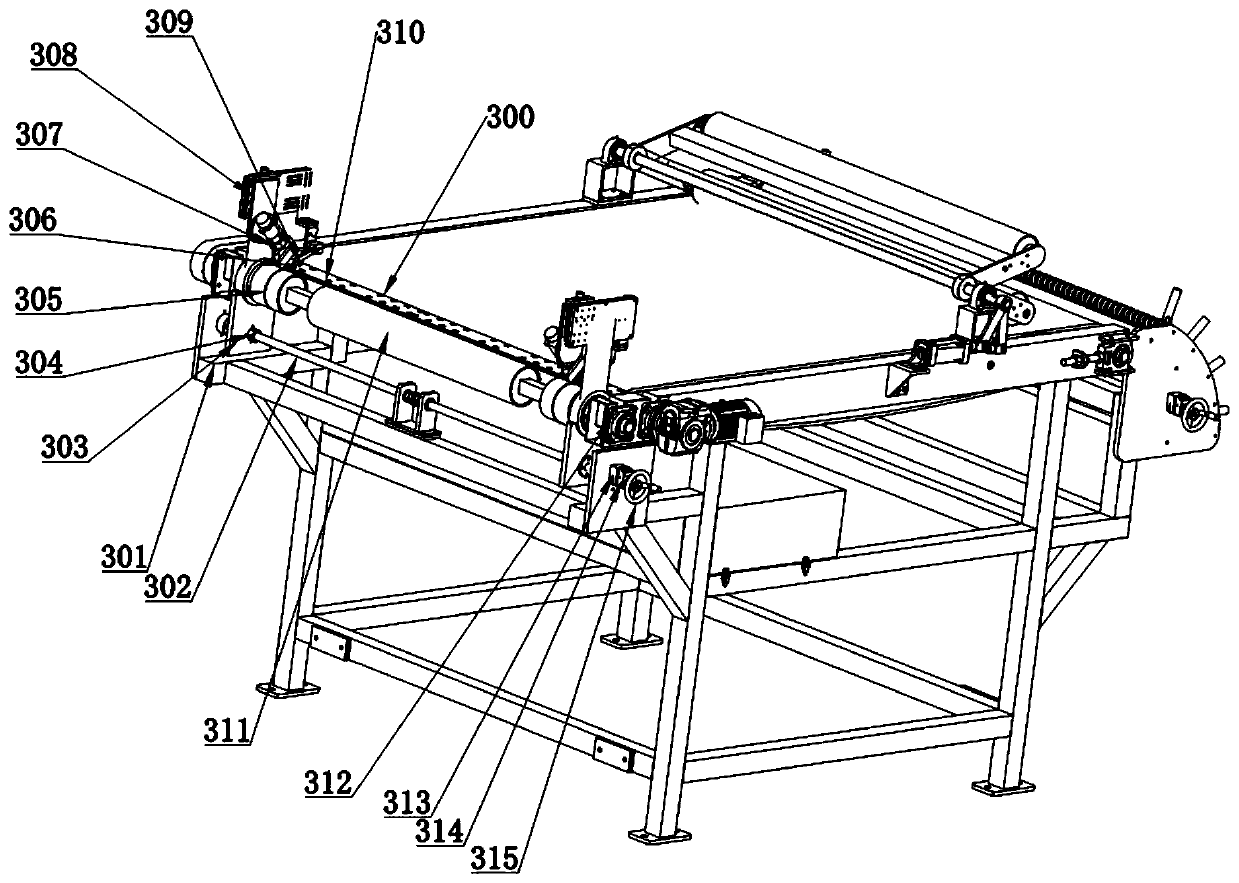

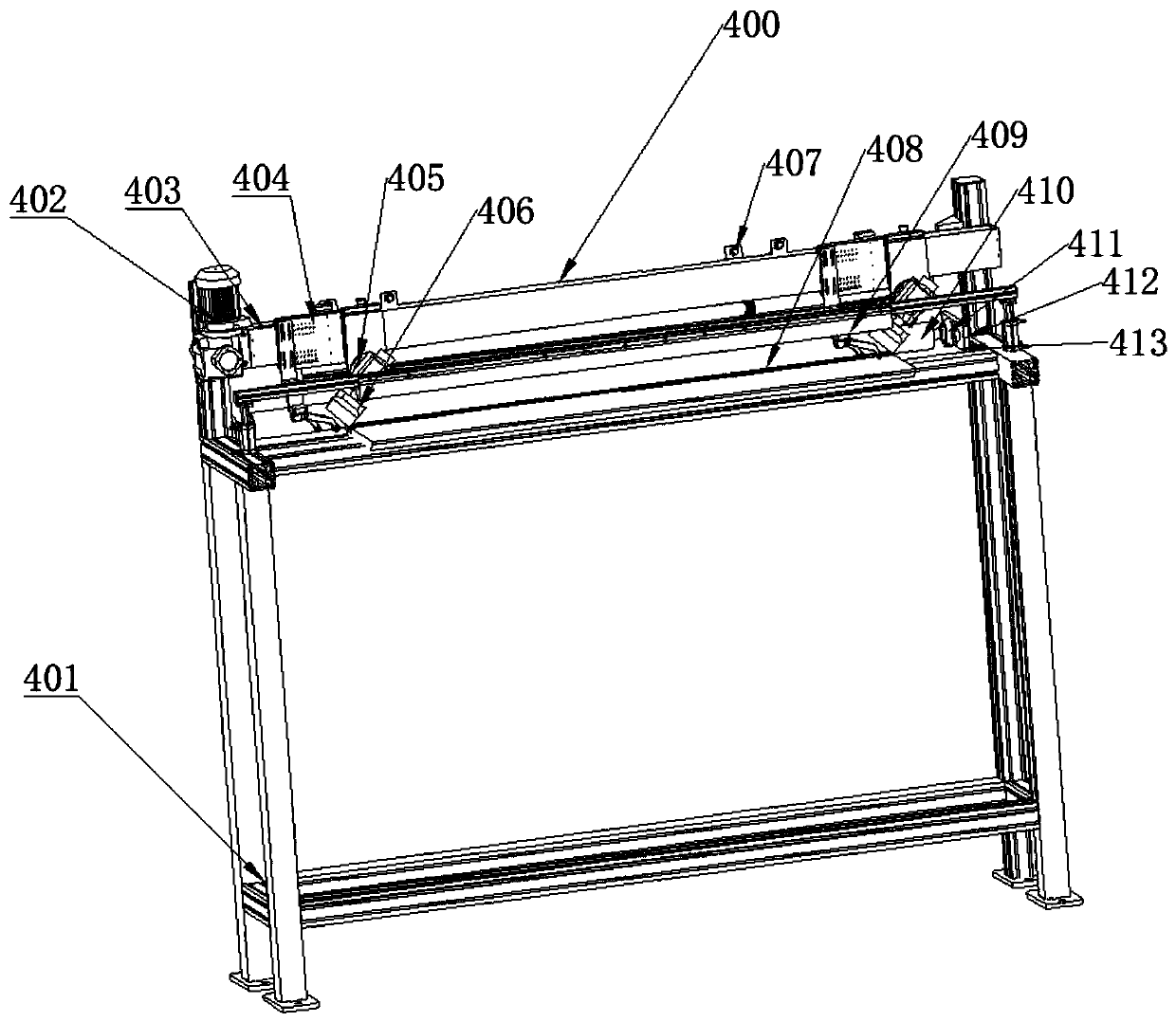

[0016] Such as Figures 1 to 3 As shown, this specific embodiment adopts the following technical solutions: an ultrasonic cutting device applied to fixed-length trimming of rubber materials, including an unwinding device 100, a conveying device 200, a trimming device 300, a cutting device 400 and a winding device 500 ; The unwinding device 100, the conveying device 200, the trimming device 300, the cutting device 400 and the winding device 500 are sequentially connected together; the specific structure of the trimming device 300 is: comprising a trimming support 301, a trimming wire Rod 302, edge trimming moving plate 303, edge trimming moving nut 304, edge trimming base film 305, edge trimming cutter 306, edge trimming cutter clamp 307, edge trimming cutter bracket 308, edge trimming pressure wheel 309, edge trimming knife Plate 310, trimming transition roller 311, trimming roller bearing 312, trimming screw rod support assembly 313, trimming display 314 and trimming hand whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com