Parallel multi-channel CNC machine tool

A CNC machine tool and multi-channel technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of untidy beam slots, position shielding, unfavorable design layout and assembly maintenance, etc. less, improve processing efficiency, and facilitate the effect of design layout and assembly maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

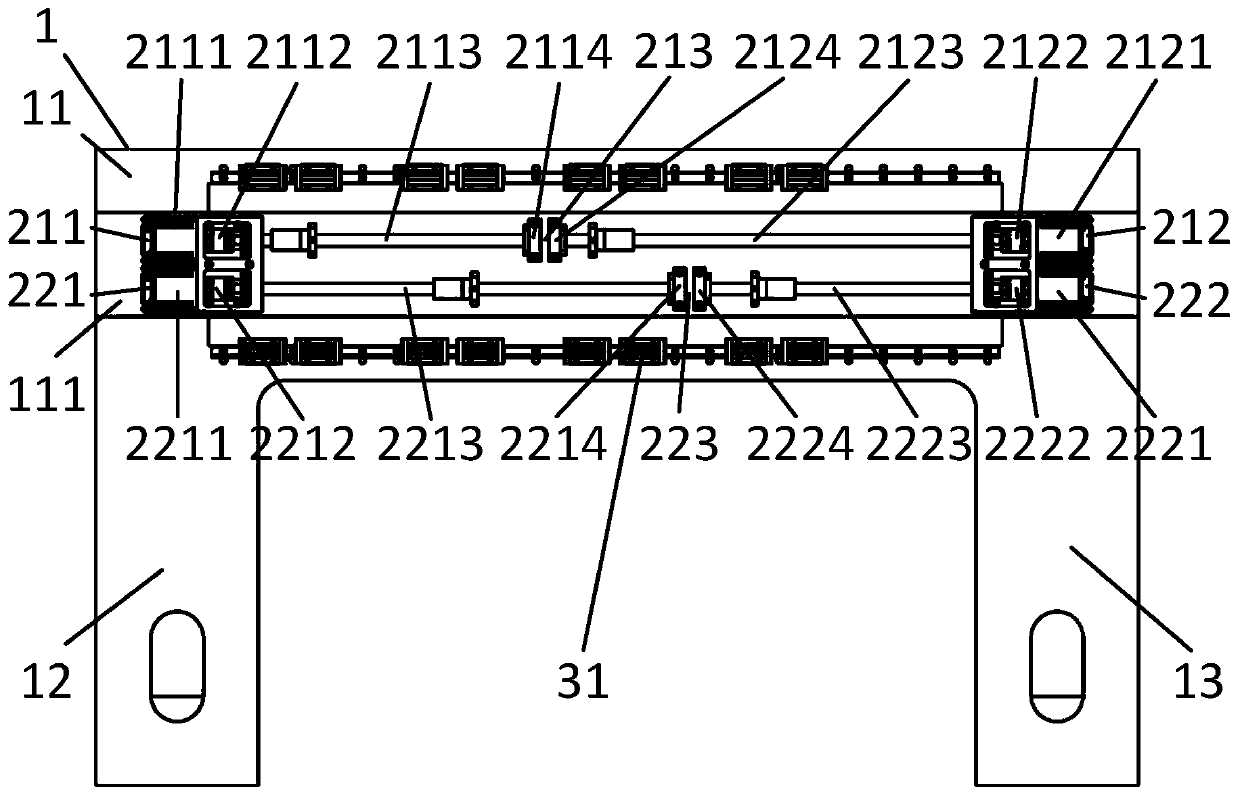

[0051] Combine below Figure 1 to Figure 3 The structure of the machine tool according to the first embodiment of the present invention will be described.

[0052] figure 1 A beam structure diagram of the machine tool according to the first embodiment of the present invention is shown.

[0053] Beam 1

[0054] Such as figure 1 As shown, the beam 1 includes a top beam 11 , a left support column 12 and a right support column 13 , and the left support column 12 and the right support column 13 are fixedly arranged at both ends of the top beam 11 . The beam 1 is in the shape of a door as a whole.

[0055] A beam groove 111 is opened on the front surface of the top beam 11 , and a ball screw transmission mechanism 2 is arranged in the beam groove 111 .

[0056] Ball screw drive mechanism 2

[0057] Such as Figure 1 to Figure 3 As shown, in this embodiment, the ball screw transmission mechanism 2 includes a first pair of ball screw transmission mechanisms 21 and a second pair...

no. 2 approach

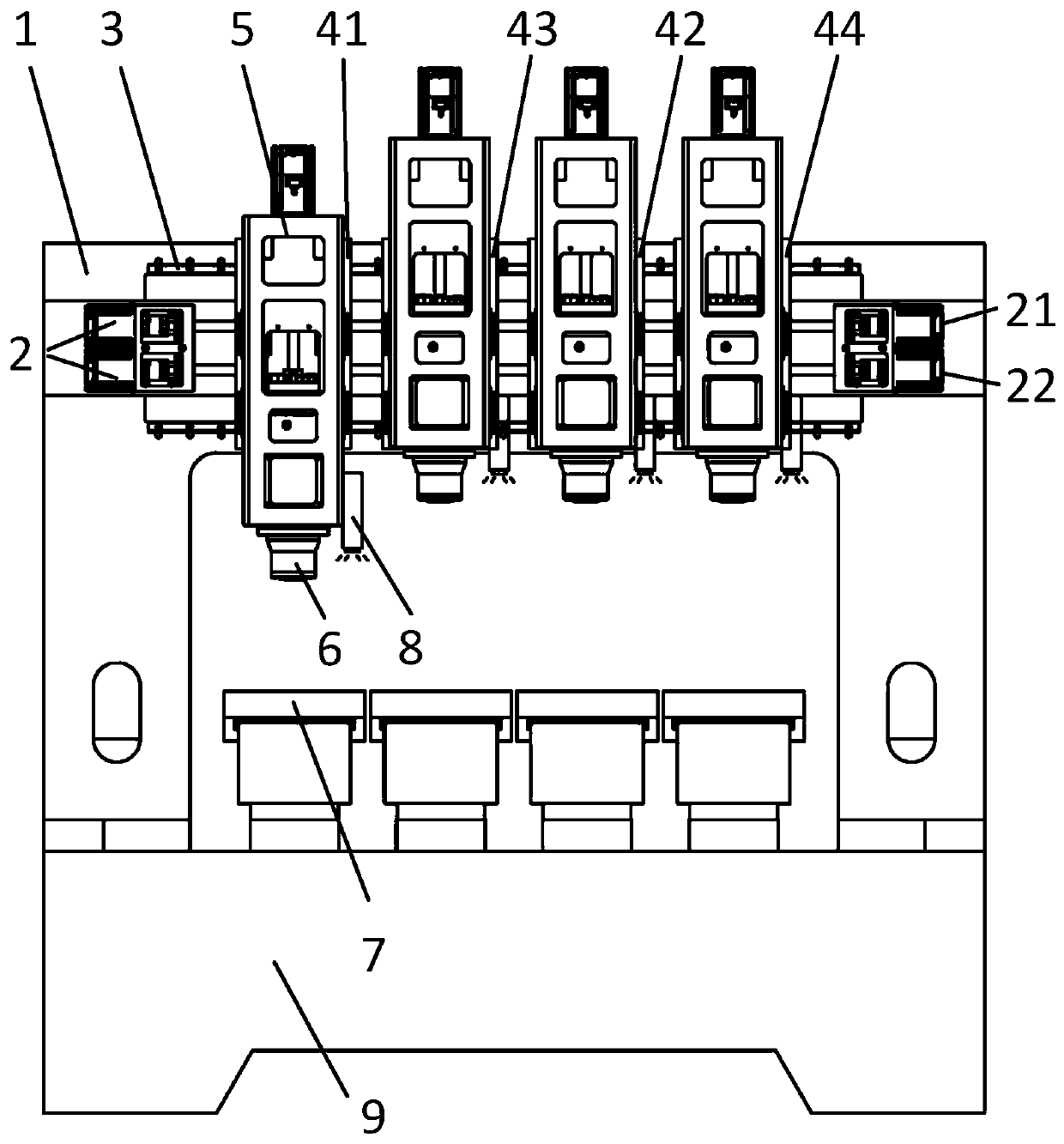

[0096] Figure 4 A beam structure diagram of a machine tool according to a second embodiment of the present invention is shown.

[0097] The beam 1, linear guide rail 3, horizontal slide 4, vertical slide 5, processing head 6, longitudinal table 7, online measuring device 8 and bed 9 in the second embodiment are the same as the beam 1 in the first embodiment. , linear guide rail 3, horizontal slide plate 4, vertical slide plate 5, processing head 6, longitudinal workbench 7, on-line measuring device 8, and bed 9 are roughly the same in structure, and the following mainly introduces the differences between this embodiment and the first embodiment place.

[0098] The difference between this embodiment and the first embodiment mainly lies in the structure of the motor driving mechanism in the ball screw transmission mechanism 2 , which will be described in detail below.

[0099] As mentioned in the first embodiment, if the first left lateral slide plate 41 is arranged on the le...

no. 3 approach

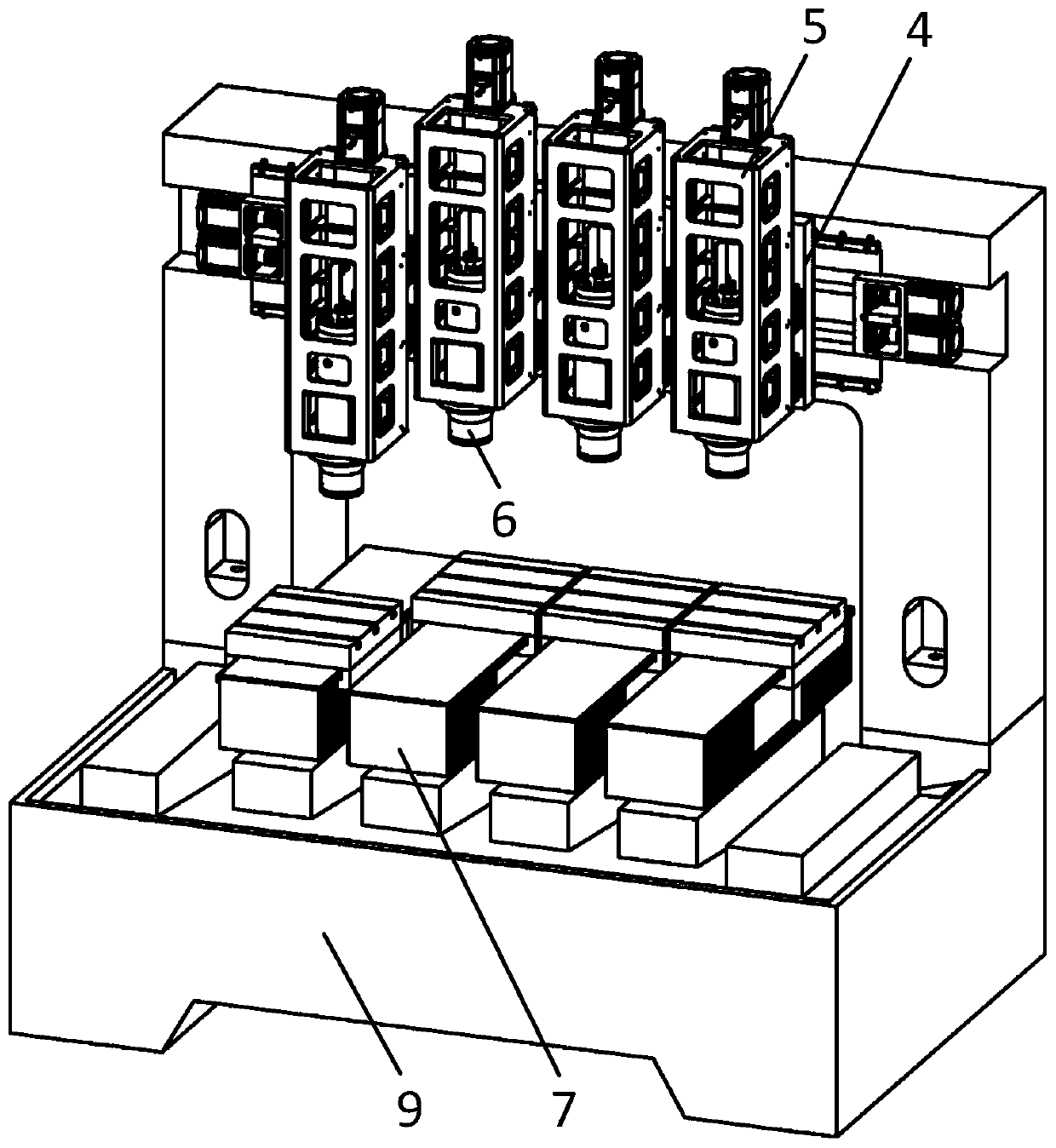

[0104] Figure 5 A beam structure diagram of a machine tool according to a third embodiment of the present invention is shown.

[0105] The beam 1, linear guide rail 3, horizontal slide 4, vertical slide 5, processing head 6, longitudinal table 7, online measuring device 8 and bed 9 in the third embodiment are the same as the beam 1 in the first embodiment. , linear guide rail 3, horizontal slide plate 4, vertical slide plate 5, processing head 6, longitudinal workbench 7, on-line measuring device 8 and bed 9 are basically the same in structure respectively, and the following mainly introduces the differences between this embodiment and the first embodiment the difference.

[0106] The difference between this embodiment and the first embodiment mainly lies in the structure of the ball screw transmission mechanism 2, which will be described in detail below.

[0107] In this embodiment, by increasing the vertical width dimension of the beam groove 111 , a third pair of ball sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com