A method for preparing silver micron hollow frame structure material

A frame structure and hollow technology, which is applied in the field of metal silver material preparation, can solve the problems of lack of preparation methods for silver micron hollow frame structure materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Prepare silver micron hollow frame structure material according to the following steps

[0020] (1) At room temperature, configure AgNO with a concentration of 0.002mol / L 3 Aqueous solution; according to preset HF, FeSO 4 and AgNO 3 The molar ratio of 5:1.1:1 to AgNO 3 Add HF and FeSO to aqueous solution 4 , the stirring speed is set at 200 rpm, and the stirring is performed to obtain a clear mixed solution;

[0021] (2) The above mixed solution was placed in a water bath at a temperature of 35°C, and the reaction time was maintained for 1 h, and the resulting product was centrifuged, washed, and dried to obtain a silver micron hollow frame structure material.

Embodiment 2

[0022] Embodiment 2: Prepare silver micron hollow frame structure material according to the following steps

[0023] (1) At room temperature, configure AgNO with a concentration of 0.006 mol / L 3 Aqueous solution; according to preset HF, FeSO 4 and AgNO 3 The molar ratio of 15:1.1:1, to AgNO 3 Add HF and FeSO to aqueous solution 4 , the stirring speed is set at 200 rpm, and the stirring is performed to obtain a clear mixed solution;

[0024] (2) Put the above mixed solution in a water bath at a temperature of 50°C, and keep the reaction time for 0.75h, centrifuge, wash, and dry the resulting product to obtain a silver micron hollow frame structure material.

Embodiment 3

[0025] Embodiment 3: Prepare silver micron hollow frame structure material according to the following steps

[0026] (1) At room temperature, configure AgNO with a concentration of 0.01 mol / L 3 Aqueous solution; according to preset HF, FeSO 4 and AgNO 3 The molar ratio of 25:1.1:1, to AgNO 3 Add HF and FeSO to aqueous solution 4 , the stirring speed is set at 200 rpm, and the stirring is performed to obtain a clear mixed solution;

[0027] (2) The above mixed solution was placed in a water bath at a temperature of 65°C, and the reaction time was kept for 0.5h, and the resulting product was centrifuged, washed, and dried to obtain a silver micron hollow frame structure material.

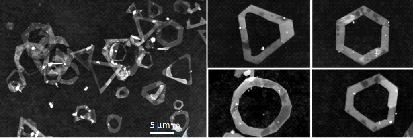

[0028] The scanning electron microscope picture of the silver micron hollow frame structure material of embodiment 1-3 gained is as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com