A Large Vibration Horn for Ultrasonic High-speed Vibration Assisted Machining

A technology of auxiliary processing and horn, which is applied in the direction of vibrating fluid, metal processing equipment, manufacturing tools, etc., which can solve the problems of affecting broaching efficiency, shortening the service life of tools, and being unable to guarantee a non-interference state, so as to achieve high vibration The effect of speed, prolonging service life and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

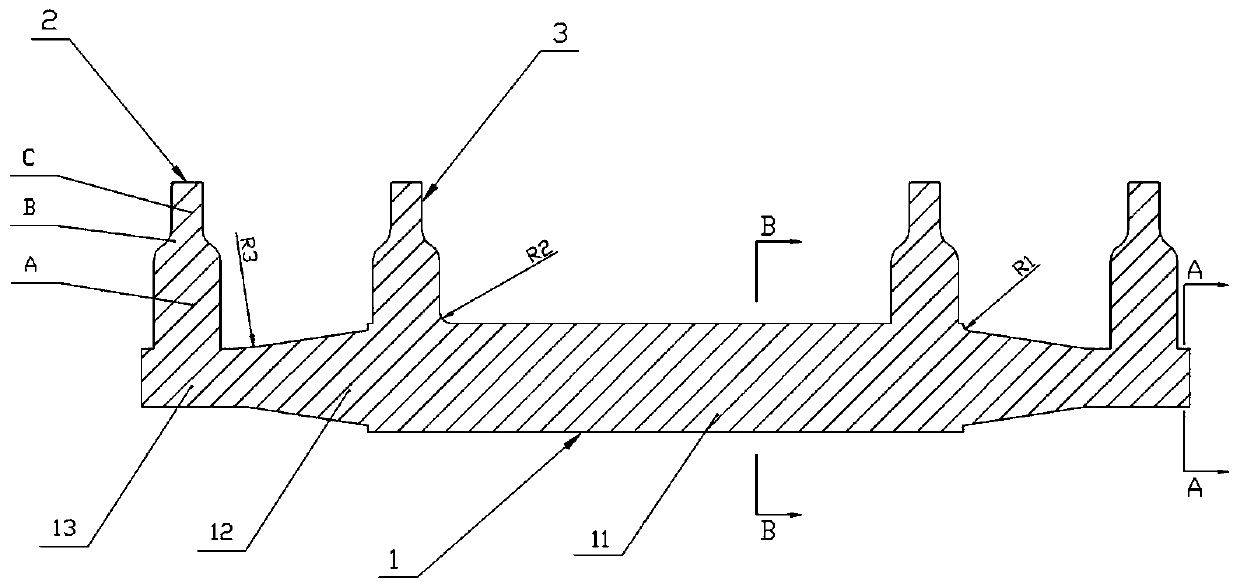

[0028] When the inventor was designing, it was considered that in processing the tenon groove of the turbine disk, since a profile of the tenon groove is a curve (in the X-Y plane), the chip formed during the cutting process is a curved surface. In ultrasonic vibration assisted machining, the tool When vibrating relative to the workpiece along the x and y axes, interference will occur. There is no guarantee that the cutter teeth will be out of contact with the workpiece within one vibration frequency cycle.

[0029] In order to solve the above interference problems, the inventor hopes to control the vibration transmission system in the X, Y, and Z directions in the cutting vibration transmission system to achieve no motion interference, that is, to realize the cutting tool and the workpiece within a part of the cycle. Completely out of contact in x, y, z directions. Therefore, according to the vibration characteristics, the inventor designed this device, which can controllabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com